Pressure swing adsorption

Pressure swing adsorption (PSA) is a technology used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material. It operates at near-ambient temperatures and differs significantly from cryogenic distillation techniques of gas separation. Specific adsorbent materials (e.g., zeolites, activated carbon, molecular sieves, etc.) are used as a trap, preferentially adsorbing the target gas species at high pressure. The process then swings to low pressure to desorb the adsorbed material.

Process

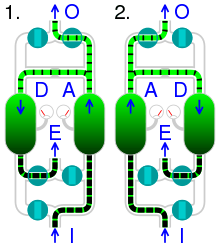

| I | compressed air input | A | adsorption | |

|---|---|---|---|---|

| O | oxygen output | D | desorption | |

| E | exhaust |

Pressure swing adsorption processes utilize the fact that under high pressure, gases tend to be attracted to solid surfaces, or "adsorbed". The higher the pressure, the more gas is adsorbed. When the pressure is reduced, the gas is released, or desorbed. PSA processes can be used to separate gases in a mixture because different gases tend to be attracted to different solid surfaces more or less strongly. If a gas mixture such as air is passed under pressure through a vessel containing an adsorbent bed of zeolite that attracts nitrogen more strongly than oxygen, part or all of the nitrogen will stay in the bed, and the gas exiting the vessel will be richer in oxygen than the mixture entering. When the bed reaches the end of its capacity to adsorb nitrogen, it can be regenerated by reducing the pressure, thus releasing the adsorbed nitrogen. It is then ready for another cycle of producing oxygen-enriched air.

This is the process used in medical oxygen concentrators used by emphysema patients and others requiring oxygen-enriched air for breathing.

Using two adsorbent vessels allows near-continuous production of the target gas. It also permits so-called pressure equalisation, where the gas leaving the vessel being depressurised is used to partially pressurise the second vessel. This results in significant energy savings, and is common industrial practice.

Adsorbents

Aside from their ability to discriminate between different gases, adsorbents for PSA systems are usually very porous materials chosen because of their large specific surface areas. Typical adsorbents are activated carbon, silica gel, alumina, resin and zeolite. Though the gas adsorbed on these surfaces may consist of a layer only one or at most a few molecules thick, surface areas of several hundred square meters per gram enable the adsorption of a significant portion of the adsorbent's weight in gas. In addition to their selectivity for different gases, zeolites and some types of activated carbon called carbon molecular sieves may utilize their molecular sieve characteristics to exclude some gas molecules from their structure based on the size of the molecules, thereby restricting the ability of the larger molecules to be adsorbed.

Applications

Aside from its use to supply medical oxygen, or as a substitute for bulk cryogenic or compressed-cylinder storage, which is the primary oxygen source for any hospital, PSA has numerous other uses. One of the primary applications of PSA is in the removal of carbon dioxide (CO2) as the final step in the large-scale commercial synthesis of hydrogen (H2) for use in oil refineries and in the production of ammonia (NH3). Refineries often use PSA technology in the removal of hydrogen sulfide (H2S) from hydrogen feed and recycle streams of hydrotreating and hydrocracking units. Another application of PSA is the separation of carbon dioxide from biogas to increase the methane (CH4) ratio. Through PSA the biogas can be upgraded to a quality similar to natural gas. This includes a process in landfill gas utilization to upgrade landfill gas to utility-grade high purity methane gas to be sold as natural gas.[1]

PSA is also used in:-

- Hypoxic air fire prevention systems to produce air with a low oxygen content.

- On purpose propylene plants via propane dehydrogenation. They consist of a selective medium for the preferred adsorption of methane and ethane over hydrogen.[2]

- Industrial nitrogen generator units which employ the PSA technique produce high purity nitrogen gas (up to 99.9995%) from a supply of compressed air. But such PSA are more fitted to supply intermediate ranges of purity and flows. Capacities of such units are given in Nm³/h, normal cubic meters per hour, one Nm³/h being equivalent to 1000 liters per hour under any of several standard conditions of temperature, pressure, and humidity.

- for nitrogen : from 100 Nm³/h at 99.9% purity, to 9000 Nm³/h at 97% purity ;

- for oxygen : up to 1500 Nm³/h with a purity between 88% and 93%.[3]

Research is currently underway for PSA to capture CO2 in large quantities from coal-fired power plants prior to geosequestration, in order to reduce greenhouse gas production from these plants.[4][5]

PSA has also been discussed as a future alternative to the non-regenerable sorbent technology used in space suit Primary Life Support Systems, in order to save weight and extend the operating time of the suit.[6]

Variations of PSA technology

Double Stage PSA

(DS-PSA, sometimes referred to as Dual Step PSA). With this variation of PSA developed for use in Laboratory Nitrogen Generators generation of nitrogen gas is divided into two steps: in the first step, the compressed air is forced to pass through a carbon molecular sieve to produce nitrogen at a purity of approximately 98%; in the second step this nitrogen is forced to pass into a second carbon molecular sieve and the nitrogen gas reaches a final purity up to 99.999%. The purge gas from the second step is recycled and partially used as feed gas in the first step.

In addition, the purge process is supported by active evacuation for better performance in the next cycle. The goals of both of these changes is to improve efficiency over a conventional PSA process.

The DS-PSA is also applied to up levels oxygen concentration in this case a zeolite aluminum silica based adsorb Nitrogen in the first stage focusing Oxygen 95%, and in the second stage the molecular sieve carbon-based adsorbs the residual nitrogen in a reverse cycle, concentrating to 99% oxygen.

Rapid PSA

Rapid pressure swing adsorption or RPSA is frequently used in portable oxygen concentrators. It allows a significant reduction in the size of the adsorbent bed when high purity is not essential and feed gas can be discarded.[7] It works by quickly cycling the pressure while alternately venting opposite ends of the column at the same rate. This means that unadsorbed gases progress along the column much faster and are vented at the distal end, while adsorbed gases do not get the chance to progress and are vented at the proximal end.[8]

See also

- Adsorption – Physical phenomenon of adhesion

- Gas separation – Techniques to provide multiple products or purify a product

- Hydrogen pinch

- Hydrogen purifier

- Industrial gas – Gaseous materials produced for use in industry

- Oxygen concentrator – A device which removes nitrogen from air

- Compressed air dryer

- Vacuum swing adsorption

References

- "SWANA 2012 Excellence Award Application "Landfill Gas Control" Seneca Landfill, Inc" (PDF): 8. Retrieved 13 October 2016. Cite journal requires

|journal=(help) - Propylene Production via Propane Dehydrogenation, Technology Economics Program. Intratec. 2012. ISBN 9780615661025.

- Air Products and Chemicals, Inc (2009). "Systèmes de production de gaz PRISM®" (PDF) (in French).

- http://www.co2crc.com.au Archived August 19, 2006, at the Wayback Machine

- Grande, Carlos A.; Cavenati, Simone, eds. (2005), "Pressure Swing Adsorption for Carbon Dioxide Sequesteration", 2nd Mercosur Congress on Chemical Engineering

- Alptekin, Gokhan (2005-01-08). "An Advanced Rapid Cycling CO2 and H2O Control System for PLSS". NASA. Retrieved 2007-02-24.

- Chai, S. W.; Kothare, M. V.; Sircar, S. (2011). "Rapid Pressure Swing Adsorption for Reduction of Bed Size Factor of a Medical Oxygen Concentrator". Industrial & Engineering Chemistry Research. 50 (14): 8703. doi:10.1021/ie2005093.

- Ruthven, Douglas M.; Shamsuzzman Farooq, Kent S. Knaebel (1993). Pressure Swing Adsorption. Wiley-VCH. ISBN 9780471188186.