Acrylic acid

| |

| |

| Names | |

|---|---|

| Preferred IUPAC name

Prop-2-enoic acid | |

| Other names

Acrylic acid Acroleic acid Ethylenecarboxylic acid Propenoic acid Vinylformic acid | |

| Identifiers | |

3D model (JSmol) |

|

| ChEBI | |

| ChEMBL | |

| ChemSpider | |

| DrugBank | |

| ECHA InfoCard | 100.001.071 |

| EC Number | 201-177-9 |

| KEGG | |

PubChem CID |

|

| RTECS number | AS4375000 |

| UNII | |

| |

| |

| Properties | |

| C3H4O2 | |

| Molar mass | 72.06 g·mol−1 |

| Appearance | clear, colorless liquid |

| Odor | acrid[2] |

| Density | 1.051 g/mL |

| Melting point | 14 °C (57 °F; 287 K) |

| Boiling point | 141 °C (286 °F; 414 K) |

| Miscible | |

| log P | 0.28[3] |

| Vapor pressure | 3 mmHg[2] |

| Acidity (pKa) | 4.25[4] |

| Viscosity | 1.3 cP at 20 °C (68 °F) |

| Hazards | |

| Main hazards | Corrosive (C), Dangerous for the environment (N) |

| Safety data sheet | MSDS |

| R-phrases (outdated) | R10 R20/21/22 R35 R50 |

| S-phrases (outdated) | S26 S36/37/39 S45 S61 |

| NFPA 704 | |

| Flash point | 68 °C (154 °F; 341 K) |

| 429 °C (804 °F; 702 K) | |

| Explosive limits | 2.4%-8.02%[2] |

| US health exposure limits (NIOSH): | |

PEL (Permissible) |

none[2] |

REL (Recommended) |

TWA 2 ppm (6 mg/m3) [skin][2] |

IDLH (Immediate danger) |

N.D.[2] |

| Related compounds | |

Other anions |

acrylate |

Related carboxylic acids |

acetic acid propionic acid lactic acid 3-hydroxypropionic acid malonic acid butyric acid crotonic acid |

Related compounds |

allyl alcohol propionaldehyde acrolein methyl acrylate |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

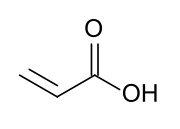

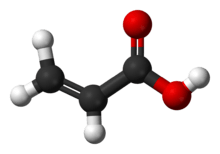

Acrylic acid (IUPAC: propenoic acid) is an organic compound with the formula CH2=CHCOOH. It is the simplest unsaturated carboxylic acid, consisting of a vinyl group connected directly to a carboxylic acid terminus. This colorless liquid has a characteristic acrid or tart smell. It is miscible with water, alcohols, ethers, and chloroform. More than a million tons are produced annually.[5]

Production

Acrylic acid is produced from propylene, which is a byproduct of ethylene and gasoline production:

- CH2=CHCH3 + 3⁄2 O2 → CH2=CHCO2H + H2O

Because propane is a significantly cheaper raw material than propylene, considerable research efforts are being undertaken to develop a process based on the one-step selective oxidation of propane to acrylic acid.[6][7][8][9] Carboxylating ethylene to acrylic acid under supercritical carbon dioxide condition is thermodynamically possible when an efficient catalyst is developed.[10]

Because acrylic acid and its esters have long been valued commercially, many other methods have been developed, but most have been abandoned for economic or environmental reasons. An early method was the hydrocarboxylation of acetylene ("Reppe chemistry"):

- HCCH + CO + H2O → CH2=CHCO2H

This method requires nickel carbonyl and high pressures of carbon monoxide. It was once manufactured by the hydrolysis of acrylonitrile, which is derived from propene by ammoxidation, but was abandoned because the method cogenerates ammonium derivatives. Other now abandoned precursors to acrylic acid include ethenone and ethylene cyanohydrin.[5]

Dow Chemical Company and its partner OPX Biotechnologies are investigating using fermented sugar to produce 3-hydroxypropionic acid (3HP), an acrylic-acid precursor.[11] The goal is to reduce greenhouse-gas emissions.[12]

Reactions and uses

Acrylic acid undergoes the typical reactions of a carboxylic acid. When reacted with an alcohol, it forms the corresponding ester. The esters and salts of acrylic acid are collectively known as acrylates (or propenoates). The most common alkyl esters of acrylic acid are methyl, butyl, ethyl, and 2-ethylhexyl acrylate.

Acrylic acid and its esters readily combine with themselves (to form polyacrylic acid) or other monomers (e.g. acrylamides, acrylonitrile, vinyl compounds, styrene, and butadiene) by reacting at their double bond, forming homopolymers or copolymers, which are used in the manufacture of various plastics, coatings, adhesives, elastomers, as well as floor polishes and paints.

Acrylic acid is a compound, which is used of many industries like the diaper industry, the water treatment industry or the textiles industry. On a worldwide scale the consumption rate of acrylic acid is projected to reach more than an estimated 8,000 kilo tons, by 2020. This increase is expected to occur as a result of using this product in new applications, including personal care products, detergents and products that are used for adult incontinence.[13]

Substituents

As a substituent acrylic acid can be found as an acyl group or a carboxyalkyl group, depending on the removal of the group from the molecule. More specifically, these are:

- The acryloyl group, with the removal of the −OH from carbon-1.

- The 2-carboxyethenyl group, with the removal of a −H from carbon-3. This substituent group is found in chlorophyll.

Safety

Acrylic acid is severely irritating and corrosive to the skin and the respiratory tract. Eye contact can result in severe and irreversible injury. Low exposure will cause minimal or no health effects, while high exposure could result in pulmonary edema. The LD50 is 340 mg/kg (rat, oral).

Acrylic acid is a constituent of tobacco smoke.[14]

See also

References

- ↑ Merck Index, 11th Edition, 124.

- 1 2 3 4 5 6 "NIOSH Pocket Guide to Chemical Hazards #0013". National Institute for Occupational Safety and Health (NIOSH).

- ↑ "Acrylic acid_msds".

- ↑ Dippy, J.F.J.; Hughes, S.R.C.; Rozanski, A. (1959). J. Chem. Soc.: 2492.

- 1 2 Takashi Ohara, Takahisa Sato, Noboru Shimizu, Günter Prescher Helmut Schwind, Otto Weiberg, Klaus Marten, Helmut Greim "Acrylic Acid and Derivatives" in Ullmann's Encyclopedia of Industrial Chemistry 2003, Wiley-VCH, Weinheim. doi: 10.1002/14356007.a01_161.pub2

- ↑ Kinetic studies of propane oxidation on Mo and V based mixed oxide catalysts (PDF). 2011.

- ↑ "The reaction network in propane oxidation over phase-pure MoVTeNb M1 oxide catalysts" (PDF). Journal of Catalysis. 311: 369–385. 2014. doi:10.1016/j.jcat.2013.12.008.

- ↑ "Multifunctionality of Crystalline MoV(TeNb) M1 Oxide Catalysts in Selective Oxidation of Propane and Benzyl Alcohol". ACS Catalysis. 3 (6): 1103–1113. 2013. doi:10.1021/cs400010q.

- ↑ "Surface chemistry of phase-pure M1 MoVTeNb oxide during operation in selective oxidation of propane to acrylic acid" (PDF). Journal of Catalysis. 285: 48–60. 2012. doi:10.1016/j.jcat.2011.09.012.

- ↑ Sakakura, Toshiyasu; Choi, Jun-Chul; Yasuda, Hiroyuki (13 June 2007). "Transformation of Carbon dioxide". Chemical Reviews. American Chemical Society. 107 (6): 2365–2387. doi:10.1021/cr068357u. PMID 17564481.

- ↑ Sweet Deal: Dow and Partner Cook up Sugar-to-Acrylic Plan. Durabilityanddesign.com. Retrieved on 2012-05-24.

- ↑ Better Bugs to Make Plastics, Technology Review, September 20, 2010, retrieved January 9, 2012. Technologyreview.com (2010-09-20). Retrieved on 2012-05-24.

- ↑ "Acrylic acid market". Retrieved 2018-05-30.

- ↑ Talhout, Reinskje; Schulz, Thomas; Florek, Ewa; Van Benthem, Jan; Wester, Piet; Opperhuizen, Antoon (2011). "Hazardous Compounds in Tobacco Smoke". International Journal of Environmental Research and Public Health. 8 (12): 613–628. doi:10.3390/ijerph8020613. ISSN 1660-4601. PMC 3084482. PMID 21556207.