Shellac

Shellac is a resin secreted by the female lac bug, on trees in the forests of India and Thailand. It is processed and sold as dry flakes (pictured) and dissolved in alcohol to make liquid shellac, which is used as a brush-on colorant, food glaze and wood finish. Shellac functions as a tough natural primer, sanding sealant, tannin-blocker, odour-blocker, stain, and high-gloss varnish. Shellac was once used in electrical applications as it possesses good insulation qualities and it seals out moisture. Phonograph and 78 rpm gramophone records were made of it until they were replaced by vinyl long-playing records from the 1950s onwards.

From the time it replaced oil and wax finishes in the 19th century, shellac was one of the dominant wood finishes in the western world until it was largely replaced by nitrocellulose lacquer in the 1920s and 1930s.

Etymology

Shellac comes from shell and lac, a calque of French laque en écailles, "lac in thin pieces", later gomme-laque, "gum lac".[1] Most European languages (except Romance ones and Greek) have borrowed the word for the substance from English or from the German equivalent Schellack.

Production

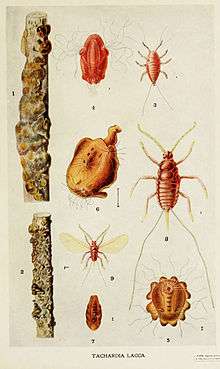

Shellac is scraped from the bark of the trees where the female lac bug, Kerria lacca (order Hemiptera, family Kerriidae, also known as Laccifer lacca), secretes it to form a tunnel-like tube as it traverses the branches of the tree. Though these tunnels are sometimes referred to as "cocoons", they are not cocoons in the entomological sense.[2] This insect is in the same superfamily as the insect from which cochineal is obtained. The insects suck the sap of the tree and excrete "sticklac" almost constantly. The least coloured shellac is produced when the insects feed on the kusum tree (Schleichera).

The number of lac bugs required to produce 1 kilogram (2.2 lb) of shellac has variously been estimated as 50,000,[3] 200,000,[4] or 300,000.[5][6] The root word lakh is a unit in Indian numbering system for 100,000 and presumably refers to the huge numbers of insects that swarm on host trees, up to 150 per square inch.[7]

The raw shellac, which contains bark shavings and lac bugs removed during scraping, is placed in canvas tubes (much like long socks) and heated over a fire. This causes the shellac to liquefy, and it seeps out of the canvas, leaving the bark and bugs behind. The thick, sticky shellac is then dried into a flat sheet and broken into flakes, or dried into "buttons" (pucks/cakes), then bagged and sold. The end-user then crushes it into a fine powder and mixes it with ethyl alcohol before use, to dissolve the flakes and make liquid shellac.

Liquid shellac has a limited shelf life (about 1 year), so is sold in dry form for dissolution before use. Liquid shellac sold in hardware stores is often marked with the production (mixing) date, so the consumer can know whether the shellac inside is still good. Some manufacturers (e.g., Zinsser) have ceased labeling shellac with the production date, but the production date may be discernible from the production lot code. Alternatively, old shellac may be tested to see if it is still usable: a few drops on glass should quickly dry to a hard surface. Shellac that remains tacky for a long time is no longer usable. Storage life depends on peak temperature, so refrigeration extends shelf life.

The thickness (concentration) of shellac is measured by the unit "pound cut", referring to the amount (in pounds) of shellac flakes dissolved in a gallon of denatured alcohol. For example: a 1-lb. cut of shellac is the strength obtained by dissolving one pound of shellac flakes in a gallon of alcohol. Most pre-mixed commercial preparations come at a 3-lb. cut. Multiple thin layers of shellac produce a significantly better end result than a few thick layers. Thick layers of shellac do not adhere to the substrate or to each other well, and thus can peel off with relative ease; in addition, thick shellac will obscure fine details in carved designs in wood and other substrates.

Shellac naturally dries to a high-gloss sheen. For applications where a flatter (less shiny) sheen is desired, products containing amorphous silica,[8] such as "Shellac Flat", may be added to the dissolved shellac.

Shellac naturally contains a small amount of wax (3%–5% by volume), which comes from the lac bug. In some preparations, this wax is removed (the resulting product being called "dewaxed shellac"). This is done for applications where the shellac will be coated with something else (such as paint or varnish), so the topcoat will adhere. Waxy (non-dewaxed) shellac appears milky in liquid form, but dries clear.

Colours and availability

Shellac comes in many warm colours, ranging from a very light blonde ("platina") to a very dark brown ("garnet"), with many varieties of brown, yellow, orange and red in between. The colour is influenced by the sap of the tree the lac bug is living on and by the time of harvest. Historically, the most commonly sold shellac is called "orange shellac", and was used extensively as a combination stain and protectant for wood panelling and cabinetry in the 20th century.

Shellac was once very common anywhere paints or varnishes were sold (such as hardware stores). However, cheaper and more abrasion- and chemical-resistant finishes, such as polyurethane, have almost completely replaced it in decorative residential wood finishing such as hardwood floors, wooden wainscoting plank panelling, and kitchen cabinets. These alternative products, however, must be applied over a stain if the user wants the wood to be coloured; clear or blonde shellac may be applied over a stain without affecting the colour of the finished piece, as a protective topcoat. "Wax over shellac" (an application of buffed-on paste wax over several coats of shellac) is often regarded as a beautiful, if fragile, finish for hardwood floors. Luthiers still use shellac to French polish fine acoustic stringed instruments, but it has been replaced by synthetic plastic lacquers and varnishes in many workshops, especially high-volume production environments.[9]

Properties

Shellac is a natural bioadhesive polymer and is chemically similar to synthetic polymers, and thus can be considered a natural form of plastic. It can be turned into a moulding compound when mixed with wood flour and moulded under heat and pressure methods, so it can also be classified as thermoplastic.

Shellac scratches more easily than most lacquers and varnishes, and application is more labour-intensive, which is why it has been replaced by plastic in most areas. But damaged shellac can easily be touched up with another coat of shellac (unlike polyurethane) because the new coat merges with and bonds to the existing coat(s). Shellac is much softer than Urushi lacquer, for instance, which is far superior with regard to both chemical and mechanical resistance.

Shellac is soluble in alkaline solutions such as ammonia, sodium borate, sodium carbonate, and sodium hydroxide, and also in various organic solvents. When dissolved in de-natured alcohol or ethanol, shellac yields a coating of good durability and hardness.

Upon mild hydrolysis shellac gives a complex mix of aliphatic and alicyclic hydroxy acids and their polymers that varies in exact composition depending upon the source of the shellac and the season of collection. The major component of the aliphatic component is aleuritic acid, whereas the main alicyclic component is shellolic acid.[10]

Shellac is UV-resistant, and does not darken as it ages (though the wood under it may do so, as in the case of pine).[4]

History

The earliest written evidence of shellac goes back 3,000 years, but shellac is known to have been used earlier.[4] According to the Mahabharata, an entire palace was built out of dried shellac.[4]

Shellac was in rare use as a dyestuff for as long as there was a trade with the East Indies. Merrifield[11] cites 1220 for the introduction of shellac as an artist's pigment in Spain. Lapis lazuli, an ultramarine pigment from Afghanistan, was already being imported long before this.

The use of overall paint or varnish decoration on large pieces of furniture was first popularised in Venice (then later throughout Italy). There are a number of 13th-century references to painted or varnished cassone, often dowry cassone that were made deliberately impressive as part of dynastic marriages. The definition of varnish is not always clear, but it seems to have been a spirit varnish based on gum benjamin or mastic, both traded around the Mediterranean. At some time, shellac began to be used as well. An article from the Journal of the American Institute of Conservation describes the use of infrared spectroscopy to identify a shellac coating on a 16th-century cassone.[12] This is also the period in history where "varnisher" was identified as a distinct trade, separate from both carpenter and artist.

Another use for shellac is sealing wax. Woods's The Nature and Treatment of Wax and Shellac Seals[13] discusses the various formulations, and the period when shellac started to be added to the previous beeswax recipes.

The "period of widespread introduction" would seem to be around 1550 to 1650, when the substance moves from being a rarity on highly decorated pieces to being described in the standard texts of the day.

Uses

Historical

In the early- and mid-twentieth century, orange shellac was used as a one-product finish (combination stain and varnish-like topcoat) on decorative wood panelling used on walls and ceilings in homes, particularly in the US. In the American South, use of knotty pine plank panelling covered with orange shellac was once as common in new construction as drywall is today. It was also often used on kitchen cabinets and hardwood floors, prior to the advent of polyurethane.

Until the advent of vinyl, most gramophone records were pressed from shellac compounds.[14][15] From 1921 to 1928, 18,000 tons of shellac were used to create 260 million records for Europe.[7] In the 1930s, it was estimated that half of all shellac was used for gramophone records.[16] Use of shellac for records was common until the 1950s and continued into the 1970s in some non-Western countries.

Until recent advances in technology, shellac (French polish) was the only glue used in the making of ballet dancers' pointe shoes, to stiffen the box (toe area) to support the dancer en pointe. Many manufacturers of pointe shoes still use the traditional techniques, and many dancers use shellac to revive a softening pair of shoes.[17]

Shellac was historically used as a protective coating on paintings.

Sheets of Braille were coated with shellac to help protect them from wear due to being read by hand.

Shellac was used from the mid-nineteenth century to produce small moulded goods such as picture frames, boxes, toilet articles, jewelry, inkwells and even dentures. Advances in plastics have rendered shellac obsolete as a moulding compound.

Shellac (both orange and white varieties) was used both in the field and laboratory to glue and stabilise dinosaur bones until about the mid-1960s. While effective at the time, the long-term negative effects of shellac (being organic in nature) on dinosaur bones and other fossils is debated, and shellac is very rarely used by professional conservators and fossil preparators today.

Shellac was once used for fixing inductor, motor, generator and transformer windings, where it was applied directly to single-layer windings in an alcohol solution. For multi-layer windings, the whole coil was submerged in shellac solution, then drained and placed in a warm place to allow the alcohol to evaporate. The shellac then locks the wire turns in place, provides extra insulation and prevents movement and vibration, reducing buzz and hum. In motors and generators it also helps transfer force generated by magnetic attraction and repulsion from the windings to the rotor or armature. In more recent times, synthetic resins, such as glyptol, (Glyptal), have been substituted for the shellac. Some applications use shellac mixed with other natural or synthetic resins, such as pine resin or phenol-formaldehyde resin, of which Bakelite is the best known, for electrical use. Mixed with other resins, barium sulfate, calcium carbonate, zinc sulfide, aluminium oxide and/or cuprous carbonate (malachite), shellac forms a component of heat-cured capping cement used to fasten the caps or bases to the bulbs of electric lamps.

Current

It is the central element of the traditional "French polish" method of finishing furniture, fine string instruments, and pianos.

Shellac, edible, is used as a glazing agent on pills (see excipient) and sweets, in the form of pharmaceutical glaze (or, confectioner's glaze). Because of its acidic properties (resisting stomach acids), shellac-coated pills may be used for a timed enteric or colonic release.[18] Shellac is used as a 'wax' coating on citrus fruit to prolong its shelf/storage life. It is also used to replace the natural wax of the apple, which is removed during the cleaning process.[19] When used for this purpose, it has the food additive E number E904.

Shellac coating applied with either a standard or modified Huon-Stuehrer nozzle, can be economically micro-sprayed onto various smooth sweets, such as chocolate coated peanuts. Irregularities on the surface of the product being sprayed typically result in the formation of unsightly aggregates ("lac-aggs") which precludes the use of this technique on foods such as walnuts or raisins (however, chocolate-coated raisins being smooth surfaced, are able to be sprayed successfully using a modified Huon-Stuehrer nozzle).

Because it is compatible with most other finishes, shellac is also used as a barrier or primer coat on wood to prevent the bleeding of resin or pigments into the final finish, or to prevent wood stain from blotching.[2]

Shellac is an odour and stain blocker and so is often used as the base of "solves all problems" primers. Although its durability against abrasives and many common solvents is not very good, shellac provides an excellent barrier against water vapour penetration. Shellac-based primers are an effective sealant to control odours associated with fire damage.

Shellac has traditionally been used as a dye for cotton and, especially, silk cloth in Thailand, particularly in the north-eastern region.[20] It yields a range of warm colours from pale yellow through to dark orange-reds and dark ochre.[21] Naturally dyed silk cloth, including that using shellac, is widely available in the rural northeast, especially in Ban Khwao District, Chaiyaphum province. The Thai name for the insect and the substance is "khrang" (Thai: ครั่ง).

Other

Shellac is used:

- in the tying of artificial flies for trout and salmon where the shellac was used to seal all trimmed materials at the head of the fly.

- in combination with wax for preserving and imparting a shine to citrus fruits, such as lemons.

- in dental technology, where it is occasionally used in the production of custom impression trays and (partial) denture production.

- as a binder in India ink.

- for cycling as a protective and decorative coating for bicycle handlebar tape,[22] and as a hard-drying adhesive for tubular cycle tyres, particularly for track racing.[23]

- for re-attaching ink sacs when restoring vintage fountain pens, the orange variety preferably.

- for fixing pads to the key-cups of woodwind instruments.

- for Luthier applications, to bind wood fibres down and prevent tear out on the soft spruce soundboards.

- to stiffen and impart water-resistance to felt hats, for wood finishing[24] and as a constituent of gossamer (or goss for short), a cheesecloth fabric coated in shellac and ammonia solution used in the shell of traditional silk top and riding hats.

- to increase the strength and longevity of ballet pointe shoes as a remedy for moisture weakening.[25]

- for mounting insects, in the form of a gel adhesive mixture composed of 75% ethyl alcohol.[26]

- as a binder in the fabrication of abrasive wheels,[27] imparting flexibility and smoothness not found in vitrified (ceramic bond) wheels. 'Elastic' bonded wheels typically contain plaster of paris, yielding a stronger bond when mixed with shellac; the mixture of dry plaster powder, abrasive (e.g. corundum/aluminium oxide Al2O3), and shellac are heated and the mixture pressed in a mould.

- in fireworks pyrotechnic compositions as a low-temperature fuel, where it allows the creation of pure 'greens' and 'blues'- colours difficult to achieve with other fuel mixes.

- in watchmaking, due to its low melting temperature (about 80-100 °C), to adjust and adhere pallet stones to the pallet fork. Also for securing small parts to a 'wax chuck' ( faceplate ) in a watchmakers' lathe.

- in the early twentieth century, it was used to protect some military rifle stocks.[28]

- in the cosmetic industry, shellac is known as a nail treatment that lasts longer than regular polish. It also gives it a better glossy finish.[29] It is a combination of gel and regular polish and offers a water-resistant seal among nail protection. The process consists of three steps and a UV light finish.[30] Removal of Shellac is a 15-minute process.[31]

- in Jelly Belly jelly beans, in combination with beeswax to give them their final buff and polish.[32]

- in modern traditional archery, shellac is one of the hot-melt glue/resin products used to attach arrowheads to wooden or bamboo arrow shafts.

Gallery

Blonde shellac flakes

Blonde shellac flakes- Dewaxed Bona (L) and Waxy #1 Orange (R) shellac flakes. The latter—orange shellac—is the traditional shellac used for decades to finish wooden wall paneling, kitchen cabinets and tool handles.

- Closeup of Waxy #1 Orange (L) and Dewaxed Bona (R) shellac flakes. The former—orange shellac—is the traditional shellac used for decades to finish wooden wall paneling and kitchen cabinets.

- "Quick and dirty" example of a pine board coated with 1-5 coats of Dewaxed Dark shellac (a darker version of traditional orange shellac)

References

- ↑ "shellac". Online Etymology Dictionary. Retrieved 17 March 2015.

- 1 2 Shellac, WoodworkDetails.com: Shellac as a Woodworking Finish

- ↑ Bangali Baboo; D. N. Goswami (2010). Processing, Chemistry and Application of Lac. New Delhi, India: Chandu Press. p. 4.

- 1 2 3 4 Naturalhandyman.com : DEFEND, PRESERVE, AND PROTECT WITH SHELLAC : The story of shellac

- ↑ Yacoubou, Jeanne (30 November 2010). "Q & A on Shellac". Vegetarian Resource Group. Retrieved 3 July 2014.

- ↑ Velji, Vijay (2010). "Shellac Origins and Manufacture". shellacfinishes.com. Retrieved 3 July 2014.

- 1 2 Berenbaum, May (1993). Ninety-nine More Maggots, Mites, and Munchers. University of Illinois Press. p. 27. ISBN 978-0-252-02016-2.

- ↑ American Woodworker: Tips for Using Shellac

- ↑ French polishing tutorial for guitars

- ↑ Merck Index, 9th Ed. page 8224.

- ↑ Merrifield, Mary (1849). Original Treatises on the Art of Painting. Mineola, N.Y.: Dover Publ. ISBN 0-486-40440-4.

- ↑ "Furniture finish layer identification by infrared linear mapping microspectroscopy". JAIC (Journal of the American Institute of Conservation). 31 (2, Article 6): 225 to 236. 1992.

- ↑ Woods, C. (1994). "The Nature and Treatment of Wax and Shellac Seals". Journal of the Society of Archivists (15).

- ↑ Rheding, Alexander (2006). "On the Record". Cambridge Opera Journal. 18 (1): 59-82.

- ↑ Melillo, Edward (2014). "Global Entomologies: Insects, Empires, and the 'Synthetic Age' in World History". Past & Present. 223: 233-270.

- ↑ "How Shellac Is Manufactured". The Mail (Adelaide, SA : 1912–1954). 18 December 1937. Retrieved 3 July 2014.

- ↑ "Maintenance of Pointe Shoes – Bloch Australia". Bloch Australia. Retrieved 17 March 2016.

- ↑ Shellac film coatings providing release at selected pH and method – US Patent 6620431 Archived 29 September 2007 at the Wayback Machine.

- ↑ "US Apple: Consumers – FAQs: Apples and Wax". Archived from the original on 3 December 2010. Retrieved 3 February 2012.

- ↑ Suanmuang Tulaphan, Phunsap, Silk Dyeing With Natural Dyestuffs in Northeastern Thailand, 1999, p. 26-30 (in Thai)

- ↑ Punyaprasop, Daranee (Ed.)Colour And Pattern On Native Cloth, 2001, p. 253, 256 (in Thai)

- ↑ "Shellac & Twine makes Handlebar fine". Out Your Backdoor. 21 August 2005. Retrieved 17 March 2015.

- ↑ Mounting Tubular Tires by Jobst Brandt

- ↑ Jewitt, Jeff. "Shellac: A traditional finish still yields superb results". Antique Restorers. Retrieved 16 March 2015.

- ↑ Frequently Asked Questions about pointe shoes and ribbons

- ↑ Fly Times: Shellac gel for insect mounting

- ↑ Stephen Malkin; Changsheng Guo (2008). Grinding Technology: Theory and Applications of Machining With Abrasives. Industrial Press. p. 5.

- ↑ "What kind of finish is on my stock?". Russian Mosin Nagant Forum. Retrieved 21 March 2015.

- ↑ Pisani, Katrina (5 October 2012). "The Science of Shellac". Cool Science. Archived from the original on 19 March 2015. Retrieved 21 March 2015.

- ↑ Thompson, Connie (1 June 2011). "Pros and cons of Shellac nail polish". Komo News. Retrieved 21 July 2016.

- ↑ "Remove Shellac Nail Polish (Nail Technician Process) – Broke My Nail". Broke My Nail. Retrieved 1 March 2016.

- ↑ Q&A – Jelly Belly jelly beans Archived 5 January 2014 at the Wayback Machine.

External links

| Wikimedia Commons has media related to Shellac. |

| Look up shellac in Wiktionary, the free dictionary. |

- Shellac.net US shellac vendor – properties and uses of dewaxed and non-dewaxed shellac

- The Story of Shellac (history)

- DIYinfo.org's Shellac Wiki, practical information on everything to do with shellac

- Reactive Pyrolysis-Gas Chromatography of Shellac

- Shellac A short introduction to the origin of shellac, the history of Japanning and French polishing, and how to conserve and repair these finishes sympathetically

- Shellac Application By Smith & Rodger