Double-stack rail transport

Double-stack rail transport is a form of intermodal freight transport where railroad cars carry two layers of intermodal containers. Introduced in North America in 1984, double stack has become increasingly common there, being used for nearly 70% of United States intermodal shipments. Using double stack technology, a freight train of a given length can carry roughly twice as many containers, sharply reducing transport costs per container. On most North American railroads, special well cars are used for double-stack shipment to reduce the needed vertical clearance and to lower the center of gravity of a loaded car. In addition, the well car design reduces damage in transit and provides greater cargo security by cradling the lower containers so their doors cannot be opened. A succession of larger container sizes have been introduced to further increase shipping productivity on shipments within North America.

Double-stack rail operations are growing in other parts of the world, but are often constrained by clearance and other infrastructure limitations.

Weights

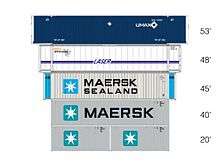

Containers have weight limits designed to allow tier transport by road trucks, which have lower weight limits than trains. A common limit for railways is 8 tonnes per metre (8.1 short ton/yd; 7.2 long ton/yd) train length and 22.5 tonnes (22.1 long tons; 24.8 short tons) per axle. A four axle container car can take 90 tonnes (99.2 short tons; 88.6 long tons). Since a container is limited to 30.5 tonnes (33.6 short tons; 30.0 long tons), even including the empty weight of the rail car, single stacking uses only part of the load capacity of the railway. A 20-foot (6.1 m) container is limited to 24 tonnes (26.5 short tons; 23.6 long tons) and two such can fit into a car for a 40-foot (12.2 m) container, or even three if double-stacking, but not four unless very high axle load is permitted. The North American railways permit two 53-foot (16.15 m) or four 20-foot (6.1 m) containers as shown in the images on this page.

Another consideration is the maximum weight of a train. A maximum length train in Europe, 750 m (2,461 ft) long can have 50 container cars with a total weight of 2,250 tonnes (2,480 short tons; 2,210 long tons), and more if 20 ft containers are included. This is not far from the limit using standard European couplers. Double-stacking requires allowing higher train weight to be meaningful, since it is higher train weights that saves costs. In the U.S., the AAR coupler used allows much higher train weight. In any case, the European loading and structure gauges do not allow double stacking.

Sizes and clearances

Double-stack cars come in a number of sizes, related to the standard sizes of the containers they are designed to carry. Well lengths of 40 ft (12.19 m), 48 ft (14.63 m) and 53 ft (16.15 m) are most common.[1] Heights range from 8 ft (2.44 m) to 9 ft 6 in (2.9 m) ("high cube").

Double stack requires a higher clearance above the tracks, or structure gauge, than do other forms of rail freight. Double-stack cars are most common in North America where intermodal traffic is heavy and electrification is less widespread; thus overhead clearances are typically more manageable. Nonetheless, North American railroads have invested large sums to raise bridges and tunnel clearances along their routes and remove other obstacles to allow greater use of double stack trains and to give them more direct routes.

CSX lists three clearance heights above top of rail for double stack service:[2]

- Doublestack 1 — 18 ft 2 in (5.54 m)

- Doublestack 2 — 19 ft 2 in (5.84 m)

- Doublestack 3 — 20 ft 2 in (6.15 m)

The last clearance offers the most flexibility, allowing two high cube containers to be stacked.

International and domestic stack trains in North America

Intermodal containers shipped by rail within in North America are primarily 53 feet (16.2 m) long, with trailer-on-flat-car (TOFC) units used as well. The 53 foot length reflects a common maximum length for highway semi-trailers, which varies by state.[3] Major domestic intermodal carriers include:

- JB Hunt

- Swift

- Schneider National

- Hub Group

Containers shipped between North America and other continents consist of mostly 40- (12.2 m) and some 45- (13.7 m) and 20-foot containers (6.1 m). Container ships only take 40's, 20's and also 45's above deck. 90% of the containers that these ships carry are 40-footers and 90% of the world's freight moves on container ships; so 80% of the world's freight moves by 40-foot containers. Most of these 40-foot containers are owned by non-U.S. companies like Maersk, MSC, and CMA CGM. The only U.S. 40-foot container companies are leasing companies like Textainer, Triton, and CAI.

History

Southern Pacific Railroad (SP), along with Malcom McLean, devised the double-stack intermodal car in 1977.[4][5] SP then designed the first car with ACF Industries that same year.[6][7] At first it was slow to become an industry standard, then in 1984 American President Lines, started working with the Union Pacific Railroad and that same year, the first all double-stack train left Los Angeles, California for South Kearny, New Jersey, under the name of "Stacktrain" rail service. Along the way the train transferred from the UP to the Chicago and North Western Railway and then to Conrail.

Double stack projects built or proposed in North America

Low bridges and narrow tunnels in various locations prevent the operation of double-stack trains until costly upgrades are made. Some Class I railroad companies in the U.S., often in partnership with government agencies, have implemented improvement programs to remove obstructions to double-stack trains. Double-stack projects include:

- Heartland Corridor (Norfolk Southern Railway) — $320 million[8]

- Norfolk Southern Crescent Corridor — $2.5 billion (estimate)

- National Gateway (CSX Transportation) — $700 million [9]

- Commonwealth Railway — $69 million[10]

- Chicago Region Environmental and Transportation Efficiency Program — $3 billion (estimate)

- Cross-Harbor Rail Tunnel proposed to connect rail freight lines in New Jersey with Long Island, New York. — $10–14 billion (estimate)

- Continental Rail Gateway (Canadian Pacific Railway), proposed tunnel between Detroit, Michigan and Windsor, Ontario to replace the existing Michigan Central Railway Tunnel. — $400 million[11]

Stacking containers

40 foot containers are the standard unit length, where all the stacking/ load bearing is. 45's, 48's, 53's all stack at the 40' coupling width. 40 foot containers or larger can be stacked on 20's if there are two 20's in a row (40' coupling width), however 20's can't be stacked on top of 40's or any other larger container. The possible double stacking patterns are:

- Two 20's in lower and one 40 (or longer) in upper stack (Allowed in India, China)

- One 40 in lower and another 40 (or longer) in upper stack (Allowed in India)

- Two 20's in lower and another set of two 20s in upper stack (possible in well type wagons, where ?)

The container coupling holes are all female and double male twistlocks are required to securely mate container stacks together.

Outside North America

Europe has more restricted loading gauge and train weight limits, so there is no operation of double-stack wagons so far.

Since electrification generally predated double stacking in Europe and New Zealand, their overhead catenary is too low to accommodate it. Many bridges and tunnels are too low for double-stacking, rebuilding for double-stack is far too expensive. However, India is building some freight-only corridors with the overhead wiring at 7.45 m (24.4 ft) above rail, which is high enough.[12] In India (passenger), Pakistan (passenger), Finland, Russia, and Kazakhstan, 25 kV AC overhead wiring is at 6.5 m (21 ft) above rail.

Because of the 1,676 mm (5 ft 6 in) broad gauge used in India and Pakistan, trains can carry standard shipping containers double-stacked on standard flat wagons, which is more economical than single containers. Standard gauge railways in North America and elsewhere must use special double-stack cars or well wagons to lower the center of gravity[13] and reduce the loading gauge. Indian Railways is able to carry containers double-stacked on standard flat wagons at 100 km/h (62 mph). (Triple-stacked operation with lower, 6-foot-6-inch (1,981 mm) containers, was mooted without success in 2006[14]). Flatbeds, in addition to being much less expensive than well wagons, can carry more containers in a given length of train.[15][16] Experiments for double stacking under 25 kV AC overhead lines have begun because of funds given by Japan.[17][18]

References

- ↑ "Guide to Railcars". Archived from the original on March 8, 2011.

- ↑ "CSX System Clearance Map— Doublestack Routes" (PDF). Archived from the original (PDF) on December 8, 2010.

- ↑ "Table 3-6: Semitrailer Length Limitations on National Truck Network by State". U.S. Department of Transportation, Federal Highway Administration.

- ↑ Cudahy, Brian J. (September–October 2006). "The Containership Revolution: Malcom McLean's 1956 Innovation Goes Global" (PDF). TR News. National Academy of Sciences (246).

- ↑ "Chronological History". Union Pacific Railroad Company.

- ↑ Kaminski, Edward S. (1999). American Car & Foundry Company: A Centennial History, 1899–1999. Wilton, California: Signature Press. ISBN 0963379100.

- ↑ "A new fleet shapes up. (High-Tech Railroading)". Railway Age. September 1, 1990 – via HighBeam Research.

- ↑ "Norfolk Southern opens Heartland Corridor". Railway Gazette International. September 9, 2010.

- ↑ "CSX Announces National Gateway to Improve Flow of Freight". CSX. May 1, 2008.

- ↑ "New Commonwealth Railway line set to open". Trains Magazine. December 16, 2010. (subscription required)

- ↑ Battagello, Dave (November 1, 2011). "Rail tunnel awaiting government funds". Windsor Star.

- ↑ "Reaching up". Railway Gazette International. August 2009. p. 17.

- ↑ "Low center of gravity". Archived from the original on March 21, 2011.

- ↑ Rao, Raghvendra (October 10, 2006). "Rlys to operate triple-stack container trains". Indian Express.

- 1 2 3 Das, Mamuni (October 15, 2007). "Spotlight on double-stack container movement". The Hindu Business Line. Retrieved February 25, 2009.

- ↑ Das, Mamuni (October 29, 2007). "Green signal for triple-stacks on diesel routes". The Hindu Business Line. Retrieved March 15, 2009.

- ↑ "Photo Gallery: IRJ". IRFCA. Archived from the original on October 7, 2008.

- ↑ Dayal, Raghu (May 2009). "Preparing to handle double-stack containers". Railway Gazette International: 46.

- ↑ "Double stacked to Perth". Parkes Champion Post. July 28, 2008.

- ↑ "2008-2024 Interstate and Hunter Valley Rail Infrastructure Strategy" (PDF). ARTC. June 30, 2008.

- ↑ "Double-decker container train arrives at Mundra". April 18, 2009.

- ↑ "Salient features". Dedicated Freight Corridor Corporation of India Ltd. Archived from the original on February 26, 2014. Retrieved April 5, 2014.

- ↑ "The Betuweroute solution". April 1, 2004. Retrieved July 22, 2011.

- ↑ "Video: Saudi Arabian Railways Dammam Bound Double Stack Container Freight Train". YouTube.