Well car

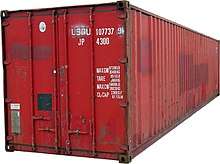

A well car, also known as a double-stack car or stack car (also well wagon), is a type of railroad car specially designed to carry intermodal containers (shipping containers) used in intermodal freight transport. The "well" is a depressed section which sits close to the rails between the wheel trucks of the car, allowing a container to be carried lower than on a traditional flatcar. This makes it possible to carry a stack of two containers per unit on railway lines (double-stack rail transport) wherever the loading gauge assures sufficient clearance. The top container is secured to the bottom container either by a bulkhead built into the car (e.g., bottom and top containers are the same dimensions of 40 ft.), or through the use of inter-box connectors (IBC). Four IBCs are needed per wellcar. In the process of an inbound train becoming an outbound train, there are four processes: unlock to unload the top container of inbound train, remove then unload bottom container, insert after loading bottom container of outbound train, lock after top container loaded.

Advantages to using well cars include increased stability due to the lower center of gravity of the load, lower tare weight, and in the case of articulated units, reduced slack action.

Double-stack cars are most common in North America where intermodal traffic is heavy and electrification is less widespread; thus overhead clearances are typically more manageable.

History

Southern Pacific Railroad (SP), along with Malcom McLean, devised the first double-stack intermodal car in 1977.[1][2] SP then designed the first car with ACF Industries that same year.[3][4] At first it was slow to become an industry standard, then in 1984 American President Lines started working with the Thrall Company to develop a refined well car and with the Union Pacific to operate a train service using the new well cars. That same year, the first all "double stack" train left Los Angeles for South Kearny, New Jersey, under the name of "Stacktrain" rail service. Along the way the train transferred from the UP to CNW and then to Conrail.

Multiple unit cars

Each unit of a double-stack car is constructed with a single well, but are often constructed with multiple units of three to five units, connected by articulated connectors. Articulated connectors are supported by the centerplate of a single truck, (often a 125-short-ton, 112-long-ton or 113-tonne capacity truck but sometimes a 150-short-ton, 134-long-ton or 136-tonne capacity one).

Also, in a number of cases, multiple single-well cars (usually 3 or 5) are connected by drawbars and share a single reporting mark.

On both types of multiple-unit cars, the units are typically distinguished by letters, with the unit on one end being the "A" unit, and the unit on the other end being the "B" unit. Middle units are labeled starting with "C", and going up to "E" for five-unit cars starting from the "A" unit and increasing towards the "B" unit.

Carrying capacity

Double-stack cars come in a number of sizes, related to the standard sizes of the containers they are designed to carry. Well lengths of 40 ft (12.19 m), 48 ft (14.63 m) and 53 ft (16.15 m) are most common. A number of 45 ft (13.72 m) wells and 56 ft (17.07 m) wells also exist. (The sizes of wells are frequently marked in large letters on the sides of cars to assist yard workers in locating suitable equipment for freight loads.)

On 40', 45', 48', or 53 cars, larger containers (45' or up) are often placed on top of smaller containers that fit in the available wells to efficiently use all available space. All wells are also capable of carrying two 20 ft ISO containers in the bottom position.[5]

Some double-stack cars have been also equipped with hitches which allow them to carry semi-trailers as well as containers. These are known as "all-purpose" well cars.

Foreign & Domestic intermodal trains

Foreign intermodal trains carry 20's, 40's, 45's and 53 foot containers to and from coastal container ports to import or export intercontinentally.

Domestic intermodal trains carry 53 foot containers plus trailer-on-flatcar and they travel throughout North America.

Econo Stack or Twin Stack well car

Econo Stack well cars are a variation of conventional well cars and their main purpose is to give the double stacked containers more support. The down side to them is they do not allow 53' containers to be stacked on top, but 45' containers still fit and are able to stack on top.

Closeup of a truck with specially adapted side bearings between two sections of an articulated well car

Closeup of a truck with specially adapted side bearings between two sections of an articulated well car- A train of well cars in Arizona

Econo Stack or Twin Stack well car

Econo Stack or Twin Stack well car

A well car also fitted with a hitch to allow truck trailer transport as well.

A well car also fitted with a hitch to allow truck trailer transport as well.

Other countries

Choke points

Low bridges and narrow tunnels in various locations prevent the operation of double-stack trains until costly upgrades are made. Some Class I railroad companies in the U.S. have initiated improvement programs to remove obstructions to double-stack trains. See Heartland Corridor (Norfolk Southern Railway) and National Gateway (CSX Transportation).

See also

References

- ↑ Cudahy, Brian J., - "The Containership Revolution: Malcom McLean’s 1956 Innovation Goes Global". - TR News. - (c/o National Academy of Sciences). - Number 246. - September–October 2006. - (Adobe Acrobat *.PDF document)

- ↑ Chronological History - Union Pacific Railroad Company

- ↑ Kaminski, Edward S. (1999). - American Car & Foundry Company: A Centennial History, 1899–1999. - Wilton, California: Signature Press. - ISBN 0963379100

- ↑ "A new fleet shapes up. (High-Tech Railroading)". - Railway Age. - (c/o HighBeam Research). - September 1, 1990

- ↑ Guide to Railcars

- ↑ Parkes article on double stacking

- ↑ "RIS 2.2 - Rail Infrastructure Strategy 2008-2024" (PDF). ARTC - Australian Rail Track Corporation (state-owned). 2008-06-30. Retrieved 2013-03-18.

Increasing the height clearance for trains to 6500mm between Parkes and Crystal Brook will allow a larger range of double-stacked container combinations to be carried

- 1 2 3 Business Line India Double Stacking

- ↑ Double stack

- ↑ http://www.irfca.org/gallery/openline/IRJ.jpg.html

- ↑ Preparing to handle double-stack containers, Raghu Dayal, Railway Gazette International May 2009, p46

Online rosters

- Double Stack Cars - A list of double stack cars by reporting mark, with various data

- RR Rolling Stock Category: Double Stack Car - Picture Archives

Magazine articles

- Mainline Modeler:

- Fortenberry, Curt & Bill McKean. - "APL Container Car". - February 1987. - p.65-69.

- Fortenberry, Curt & Robert L. Hundman. - "APL container car part II the brake system". - March 1987. - p.78-81.

- Hundman, Robert L., & Curt Fortenberry. - "APL 45-foot container car". - May 1987. - p.54-57.

- Model Railroader:

- Durrenberger, Cyril. - "SP/ACF double stack cars". - October 1983. - p.83-93.

- Model Railroading:

- Bontrager, David A. - "Articulated double stacks: a prototype overview". - June 1993. p.24-29.

- Bontrager, David A. - "The Newest Prototype Well Cars: An Abundance of Kitbashing Possibilities". August 1997. - p.46-49.

- Casdorph, David G. and Ed McCaslin. - "Gunderson's Husky-Stack: The Prototype and Detailing A-Line's HO Model". - October 1995. - p.32-37.

- Casdorph, David G. - "NSC 53' Drawbarred Well Car Roster and Pictorial". - August 2002. - p.30-33

- Geiger, Doug. - "Thrall Double-Stacks: Three-Well DTTX Drawbar-Connected Car". - October 1994. - p.50-55.

- Geiger, Doug. - "Gunderson Husky Stack Three-Well BN Drawbar-Connected Car". - July 1995. - p.48-53.

- Geiger, Doug. - "Gunderson Maxi-Stack IIIs Part I: The Prototype". - December 1995. - p.58-63.

- Geiger, Doug. - "Maxi-Stack Well Car Part I: The Prototype". - April 1997. - p.28-31.

- Mansfield, Jim. - "Thrall Five-Unit Double-Stack Car - Series TWG50J". - October 1993. - p.19-23.

- Mansfield, Jim. - "Thrall Five-Unit Double-Stack Car - Series APLX 5000". - November 1993. - p.24-25, 27-31.

- Railroad Model Craftsman:

- Panza, Jim & Chuck Yungkurth. - "Thrall's double-stack cars". - January 1989. - p.89-98.

- Panza, Jim & Bruce Keating. - "The Gunderson Husky-Stack well car". - July 1992. - p.71-75.

- Panza, Jim & William Halliar. - "Thrall stand-alone and drawbar connected well cars". - October 1992. - p.64-68.

External links

- Freight Cars

- THE GEOGRAPHY OF TRANSPORT SYSTEMS The 18 ft (5.49 m) here mentioned is too low, it is more like 20 ft 2 in (6.15 m) AAR "plate" loading gauge diagrams compared to UIC, Plate "H", (pdf & Autocad)

- A Partnership of Two Old Rivals, Time Magazine, June 7, 1954