Straddle carrier

A straddle carrier or straddle truck is a freight carrying vehicle that carries its load underneath by "straddling" it, rather than carrying it on top like a conventional truck. The advantage of the straddle carrier is its ability to load and unload without the assistance of cranes or forklifts. The lifting apparatus under the carrier is operated by the driver without any outside assistance and without leaving the driver's seat.

Lumber carriers

The straddle carrier was invented by H. B. Ross in 1913 as a road-going vehicle that could easily transport lumber around mills and yards.[1] Lumber was stacked on special pallets known as carrier blocks; the carrier would then straddle the stack, grasp and lift the carrier block, and drive off with the load.[2] Because a straddle carrier is open at both front and rear, it can transport lumber much longer than the carrier itself, over 30 m (98 ft) in length.[1]

The Ross Carrier Company (now Northwest Caster & Equipment) was founded in Seattle[3] to manufacture and market the carrier, and similar designs were later manufactured by Gerlinger, Hyster, Yale, Caterpillar, and other companies.[4] These "straddles" or "timber jinkers" were a common sight in seaports around the world until the 1970s, but were phased out as larger and faster conventional trucks came into use. An example of these road-going straddle carriers can be seen in the 1950 comedy film Watch the Birdie.

Industrial straddle carriers

Similar industrial straddle carriers are used in manufacturing and construction, both for handling oversized loads such as steel and pre-cast concrete and where transportation of special loads such as nitrogen tanks is required in restricted spaces not suitable for trucks. A key advantage of industrial straddle carriers over forklifts is the ability to load or unload a semi-trailer in a single operation, which can improve efficiency.[5][6]

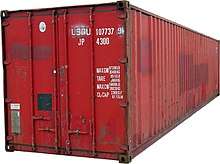

Shipping container carriers

The most common modern application for straddle carriers is in port terminals and intermodal yards where they are used for stacking and moving ISO standard containers. Straddles pick and carry containers while straddling their load and connecting to the top lifting points via a container spreader. These machines have the ability to stack containers up to 4 high. These are capable of relatively low speeds (up to 30 km/h or 18.6 mph) with a laden container. The workers that use this machinery sit at the very top seated facing the middle as they can see behind them and in front of them. Straddle carriers can lift up to 60 t (59 long tons; 66 short tons) which equals up to 2 full containers.

Gallery

Straddle carriers at work at the Port of Melbourne, Australia

Straddle carriers at work at the Port of Melbourne, Australia Straddle carriers at the Port of Copenhagen, Denmark.

Straddle carriers at the Port of Copenhagen, Denmark. Straddle carriers or SK as known at Northport, Malaysia.

Straddle carriers or SK as known at Northport, Malaysia.- Straddle carrier work at Port of Chittagong.

References

- 1 2 The Ross Carrier Company, The Ross Carrier: How It Revolutionizes Handling Methods

- ↑ Roots of Motive Power, Lumber Carrier, Ross Straddle Carrier

- ↑ Northwest Caster & Equipment, Company History

- ↑ Roots of Motive Power, Ross Carrier Company

- ↑ HSS, Processes streamlined by Straddle Carrier

- ↑ The Fabricator, Handling structural steel, one truckload at a time

External links

| Wikimedia Commons has media related to Straddle carriers. |

- "Speeding Up the Handling of Lumber with the Straddle Truck". Scientific American. 7 February 1920. Archived from the original on 2010-12-30.

- Combilift Straddle Carrier

- Liebherr straddle carrier