Quincy Mining Company Stamp Mills Historic District

|

Quincy Mining Company Stamp Mills Historic District | |

Addition to Stamp Mill Number One in 2010 | |

| |

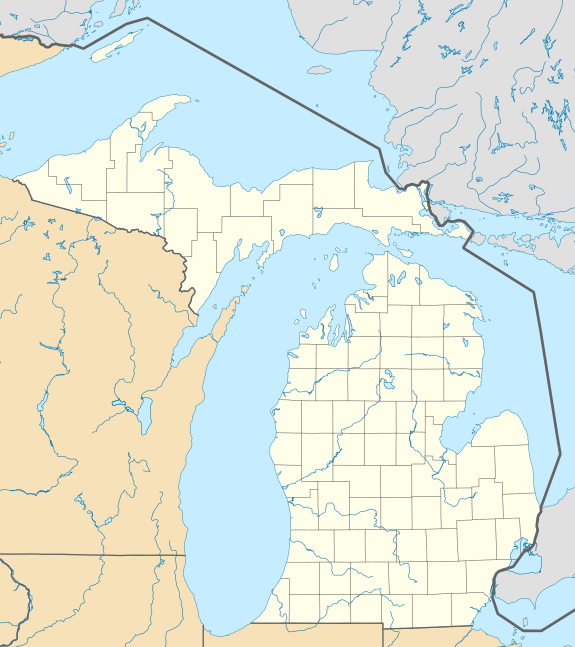

| Location | M-26 near Torch Lake, Osceola Township |

|---|---|

| Coordinates | 47°8′48″N 88°27′36″W / 47.14667°N 88.46000°WCoordinates: 47°8′48″N 88°27′36″W / 47.14667°N 88.46000°W |

| Area | 350 acres (140 ha) |

| Built | 1888 |

| Architectural style | Colonial Revival |

| NRHP reference # | 07000750[1] |

| Added to NRHP | July 18, 2007 |

The Quincy Mining Company Stamp Mills Historic District is a historic stamp mill (used to crush copper-bearing rock, separating the copper ore from surrounding rock) located on M-26 near Torch Lake, just east of Mason in Osceola Township.[2] It was listed on the National Register of Historic Places in 2007.[1]

Original stamp mill (1860–1888)

The original Quincy Stamp Mill was built in 1860 on Portage Lake[2] in Hancock, close to the Quincy Mine.[3] This facility, however, dumped an enormous amount of sand tailings into the lake, and the sand soon threatened to encroach on the navigable channel of the lake.[3] In the mid-1880s, the federal government set minimum harbor lines and stiff penalties for breaching them,[4] and eventually filed suit against the Quincy Mine for dumping in Portage Lake.[5] In addition, Quincy was in the process of acquiring the nearby Pewabic Mine, and management knew they would need to increase the company's stamping capacity.[6]

Stamp mills require a large amount of water to operate, and so are invariably located near a large body of water; this limited the range of sites in which a new mill could be placed.[7] After some analysis, the Quincy management decided on Torch Lake as the site for the new mill and purchased 300 acres on the shore,[5] some six miles east of the previous location.[3]

Construction of stamp mill (1888–1894)

Work began on the new stamp mill in 1888.[2] The first building constructed was a boarding house, followed by a dock, cistern, and foundations for other buildings.[8] In 1889, six substantial frame buildings were constructed on site, as well as a railway connecting the stamp mill to the mine, and stamping equipment was installed.[8] Mill number one was a wooden structure measuring 198 feet by 120 feet.[9] The pump and boiler house were located on the south side of the roadway that is now M-26.[9] It was a stone structure measuring 154 feet by 56 feet.[10] An elevated conduit carried water and steam over the road to the mill, and handling facilities were built at the dock.[10] The facility was completed and opened for milling in 1890.[3][8] The site originally had two stamps; a third was added immediately after opening,[9] and two more were added in 1892.[2]

More structures were added to the site over time, beginning with extensions to the dock in 1890 and 1891, an addition to the boiler house in 1891,[11] and additions to the mill in 1891 and 1892.[12] In all, the Quinct Mine spent $457,000 between 1888 and 1894 in constructing and equipping their new mill site, of which $182,000 went to the mill and its stamping equipment.[13]

Second mill and additions (1894–1922)

However, as early as 1894, mine production oustripped the capacity of the mill, and a new mill was planned.[14] The second stamp mill was built just north of the first;[2] this mill was an iron-framed structure measuring 132 feet by 216 feet.[15] It was constructed in 1899 by the Wisconsin Bridge and Iron Company at a cost of $22,450.[15] The second mill opened in late 1900 with three mills.[14][15] To service the additional capacity, new boiler and pump house buildings were also constructed.[16] Over the next two decades, minor alterations were made to the structures of the complex (including the erection of a new 175-foot smokestack for the boilerhouse in 1916)[17] while the milling process and machinery were continuously refined.

However, the rise in the price of copper during World War I provided both impetus and resources for expansion of the site.[18] Reinforced concrete and brick additions to both stamp mills were constructed in 1919;[19] the addition to mill no. 1 was 123 feet by 215 feet, and the addition to mill no. 2 was 91 feet by 132 feet.[18] The additions were equipped and functioning by 1920.[19] The mill also changed their production of electrical power, building a structure to house a new turbine near mill no. 1.[20] Construction on the new building, a brick structure measuring 36 feet by 38 feet by 45 feet high, began in 1921; the turbine was online in 1923.[21]

1890–1925 Images

|

|---|

Decline (1922 – present)

However, the mill began to decline after the end of the war. In 1922, the second mill was closed.[19] Additional equipment was installed in mill no. 1 as technology improved, including labor-saving devices installed in 1929 and 1930.[22] However, the Great Depression hit the mining industry hard, and the Quincy Mine closed in 1931, shuttering the Stamp Mills.[22]

As the Depression wound onward, copper prices rebounded, and the mine and mills were refurbished in late 1937 and re-opened on a limited scale in early 1938.[23] However, the mine was only barely profitable, and after World War II ended, and with it the price guarantees from the federal government, the mine and stamp mills closed permanently.[24]

Mill number two was demolished early,[3] as well as the original portions of mill number one, but the later additions to mill number one remain.

1978 Images

|

|---|

2010 Images

|

|---|

Further reading

- Charles F. O'Connell, "Quincy Mining Company: Stamp Mills and Milling Technology, c. 1860–1931", Quincy Mining Company, Hancock, Houghton, MI, HAER MI-2, Historic American Buildings Survey/Historic American Engineering Record/Historic American Landscapes Survey, pp. 563–640

References

- 1 2 National Park Service (2009-03-13). "National Register Information System". National Register of Historic Places. National Park Service.

- 1 2 3 4 5 Lawrence J. Molloy, A Guide to Michigan's Historic Keweenaw Copper District, retrieved November 25, 2010

- 1 2 3 4 5 "Quincy Mill". Keweenaw Free Guide. Retrieved November 26, 2010.

- ↑ Charles F. O'Connell, "Quincy Mining Company: Stamp Mills and Milling Technology, c. 1860–1931", Quincy Mining Company, Hancock, Houghton, MI, HAER MI-2, Historic American Buildings Survey/Historic American Engineering Record/Historic American Landscapes Survey, p. 594

- 1 2 O'Connell, page 597

- ↑ O'Connell, p. 590

- ↑ O'Connell, page 567

- 1 2 3 O'Connell, page 598

- 1 2 3 O'Connell, page 599

- 1 2 O'Connell, page 600

- ↑ O'Connell, page 602

- ↑ O'Connell, page 603

- ↑ O'Connell, page 601

- 1 2 O'Connell, page 604

- 1 2 3 O'Connell, page 605

- ↑ O'Connell, page 606

- ↑ O'Connell, page 620

- 1 2 O'Connell, page 621

- 1 2 3 O'Connell, page 622

- ↑ O'Connell, page 623

- ↑ O'Connell, page 624

- 1 2 O'Connell, page 627

- ↑ Charles K. Hyde, "An Economic and Business History of the Quincy Mining Company", Quincy Mining Company, Hancock, Houghton, MI, HAER MI-2, Historic American Buildings Survey/Historic American Engineering Record/Historic American Landscapes Survey, p. 263

- ↑ Hyde, page 264