Laundry detergent

Laundry detergent, or washing powder, is a type of detergent (cleaning agent) that is added for cleaning laundry. While detergent is still sold in powdered form, liquid detergents have been taking major market shares in many countries since their introduction in the 1950s.[1]

Laundry detergent pods have also been sold in the United States since 2012 when they were introduced by Procter & Gamble as Tide Pods. Earlier instances of laundry detergent pods include Salvo tablets sold in the 1960s and 1970s.[2]

History

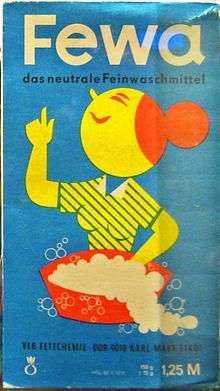

From ancient times, chemical additives were used to facilitate the mechanical washing of clothing with water. The Italians used a mix of sulfur and water with charcoal to clean cloth. Egyptians added ashes and silicates to soften water. Soaps were the first detergents.[3] The detergent effects of certain synthetic surfactants were noted in Germany in 1917, in response to shortages of soap during World War I. In the 1930s, commercially viable routes to fatty alcohols were developed, and these new materials were converted to their sulfate esters, key ingredients in the commercially important German brand FEWA, produced by BASF, and Dreft, the U.S. brand produced by Procter and Gamble. Such detergents were mainly used in industry until after World War II. By then, new developments and the later conversion of aviation fuel plants to produce tetrapropylene, used in household detergents, caused a fast growth of domestic use in the late 1940s.[4]

Soils

Washing laundry involves removing mixed soils from fiber surfaces. From a chemical viewpoint, soils can be grouped into:

- Water-soluble soils such as sugars, inorganic salts, urea, and perspiration.

- Solid particulate soils such as rust, metal oxides, soot (carbon black), carbonates, silicates, and humus.

- Hydrophobic soils such as animal fats, vegetable oils, sebum, mineral oil, and grease.

- Proteins such as blood, grass, egg, milk, (starch), and keratin from skin. These require enzymes, heat or alkali to hydrolyze and denature them into smaller parts before they can be removed by the surfactants.

- Bleachable stains such as wine, coffee, tea, fruit juices, and vegetable stains. Bleaching is an oxidation reaction which turns the colored substance into a colorless one, which either stays on the fabric or may be easier to wash out.

Soils difficult to remove are pigments and dyes, fats, resins, tar, waxes, and denatured protein.[5]

Components

Laundry detergents may contain builders (50% by weight, approximately), surfactants (15%), bleach (7%), enzymes (2 %), soil antiredeposition agents, foam regulators, corrosion inhibitors, optical brighteners, dye transfer inhibitors, fragrances, dyes, fillers and formulation aids.[6]

Builders

Builders (also called chelating or sequestering agents) are water softeners. Hard water contains calcium, magnesium and metallic cations (iron, copper, and manganese). These cations react with surfactant anions to form insoluble compounds (metallic or lime soaps) which precipitate onto fabrics and washing machines and which are difficult to remove. Builders remove the hard water ions through precipitation, chelation or ion exchange. In addition, they help remove soil by dispersion. In most European regions the water is hard. In North America, Brazil, and Japan, the water is comparatively soft.

The earliest builders were sodium carbonate (washing soda) and sodium silicate (waterglass). Since the 1930s, phosphates (sodium phosphates) and polyphosphates (sodium hexametaphosphate) were introduced, continuing with the introduction of phosphonates (HEDP, ATMP, EDTMP). These agents are now known to have serious environmental consequences leading to a drive towards more environmentally benign phosphorus-free agents, such as polycarboxylates (EDTA, NTA), citrates (trisodium citrate), silicates (sodium silicate), gluconic acid and polyacrylic acid; or ion exchange agents like zeolites.

Alkalis like soda ash precipitate hard water ions and are commonly used as builders. Additionally, they enhance washing performance. Hydrophilic fibers like cotton have a negative surface charge in water, whereas synthetic fibers are comparatively neutral. The negative charge is further increased by the adsorption of anionic surfactants. With increasing pH, soil and fibers become more negatively charged, resulting in increased mutual repulsion. This is one of the reasons why alkalis enhance wash performance, apart from effects like the saponification of fats. However, repulsive forces between soil and fibers alone do not produce satisfactory washing results even at high pH. The optimum pH range for good detergency is 9-10.5.[7]

Builder and surfactant work synergistically to achieve soil removal, and the washing effect of the builder may exceed that of the surfactant. With hydrophilic fibres like cotton, wool, polyamide and polyacrylonitrile, sodium triphosphate removes soil more effectively than a surfactant alone. With hydrophobic fibres like polyesters and polyolefins, the effectiveness of the surfactant surpasses that of the builder.

Surfactants

Surfactants are responsible for most of the cleaning performance in laundry detergent. They provide this by absorption and emulsification of soil into the water and also by reducing the water's surface tension to improve wetting.

Laundry detergents contain mostly anionic and non-ionic surfactants. Cationic surfactants are normally incompatible with anionic detergents and have poor cleaning efficiency; they are employed only for certain special effects, as fabric softeners, antistatic agents, and biocides. Zwitterionic surfactants are rarely employed in laundry detergents mainly for cost reasons. Most detergents use a combination of various surfactants to balance their performance.

Until the 1950s, soap was the predominant surfactant in laundry detergents. By the end of the 1950s so-called "synthetic detergents" (syndets) like tetrapropylenebenzenesulfonate (TPS) had largely replaced soap in developed countries.[8][9] Due to their poor biodegradability these branched alkylbenzenesulfonates were replaced with linear alkylbenzenesulfonates (LAS) in the mid-1960s. Since the 1980s, alkyl sulfates such as SDS have found increasing application at the expense of LAS.

Since the 1970s, nonionic surfactants like alcohol ethoxylates have acquired a higher share in laundry detergents. In the 1990s, glucamides appeared as co-surfactants, and alkyl polyglycosides have been used in specialty detergents for fine fabrics.[6]

Bleaches

The main targets of bleaches are oxidisible organic stains; which are usually of vegetable origin (e.g. chlorophyll, anthocyanin dyes, tannins, humic acids, and carotenoid pigments). Despite the name, modern bleaching agents do not include household bleach (sodium hypochlorite). Laundry bleaches are typically stable adducts of hydrogen peroxide, such as sodium perborate and sodium percarbonate, these are inactive as solids but will react with water to release hydrogen peroxide which performs the bleaching action. Bleach activators such as tetraacetylethylenediamine (TAED) are also increasingly used, these react with hydrogen peroxide to produce peracetic acid, which is an even more effective bleach,[6] particuarly at lower temperatures (<60 °C).

Enzymes

The use of enzymes for laundry was introduced in 1913 by Otto Rohm. The first preparation was a pancreatic extract obtained from slaughtered animals, which was unstable against alkali and bleach. Only in the latter part of the century with the availability of thermally robust bacterial enzymes did this technology become mainstream.

Enzymes are required to degrade stubborn stains composed of proteins (milk, cocoa, blood, egg yolk, grass), fats (chocolate, fats, oils), starch (flour and potato stains), and cellulose (damaged cotton fibrils, vegetable and fruit stains). Each type of stain requires a different type of enzyme: proteases (savinase) for proteins, lipases for greases, α-amylases for carbohydrates, and cellulases for cellulose.

Other ingredients

Many other ingredients are added depending on the specific application. Such additives modify the foaming properties of the product by either stabilizing or counteracting foam. Other ingredients increase or decrease the viscosity of the solution, or solubilize other ingredients. Corrosion inhibitors counteract damage to washing equipment. "Dye transfer inhibitors" prevent dyes from one article from colouring other items. "Antiredeposition agents" are used to prevent fine soil particles from reattaching to the product being cleaned. Carboxymethyl cellulose is used for this purpose.[6]

A number of ingredients affect aesthetic properties of the item to be cleaned or the detergent itself before or during use. These agents include optical brighteners, fabric softeners, and colourants. A variety of perfumes are also components of modern detergents, provided that they are compatible with the other components and do not affect the colour of the cleaned item. The perfumes are typically a mixture of many compounds, common classes include terpene alcohols (citronellol, geraniol, linalool, nerol) and their esters (linalyl acetate), aromatic aldehydes (helional, hexyl cinnamaldehyde, lilial) and synthetic musks (galaxolide).

Environmental concerns

Phosphates in detergent became an environmental concern in the 1950s and the subject of bans in later years.[10] Phosphates make laundry cleaner but also cause eutrophication, particularly with poor wastewater treatment.[11]

A recent academic study of fragranced laundry products found "more than 25 VOCs emitted from dryer vents, with the highest concentrations of acetaldehyde, acetone, and ethanol. Seven of these VOCs are classified as hazardous air pollutants (HAPs) and two as carcinogenic HAPs (acetaldehyde and benzene)".[12]

The EEC Directive 73/404/EEC stipulates an average biodegradability of at least 90 % for all types of surfactants used in detergents. The phosphate content of detergents is regulated in many countries, e.g., Austria, Germany, Italy, The Netherlands, Norway, Sweden, Switzerland, USA, Canada, and Japan.

See also

References

- ↑ https://www.smithersapex.com/liquid-vs-powder-detergents.aspx

- ↑ "Laundry detergent pods remain a health hazard". Consumer Reports. March 2013. Retrieved 11 November 2014.

- ↑ A variety of agents were used in ancient times, and even (putrescent) urine for certain applications as well as saponins and ox bile. von Georgievics, Georg; Charles Thomas Colley Salter (1902), The chemical technology of textile fibres (Google books), Scott, Greenwood, p. 81

- ↑ Spriggs, John (July 1975), An economical of the development of substitutes with some illustrative examples and implications for the beef industry (pdf), Staff paper series, University of Minnesota, pp. 34–37, retrieved 9 May 2008

- ↑

- 1 2 3 4 Eduard Smulders; et al. (2007), "Laundry Detergents", Ullmann's Encyclopedia of Industrial Chemistry (7th ed.), Wiley, pp. 1–184, doi:10.1002/14356007.a08_315.pub2

- ↑ Yangxin Yu; Jin Zhao; Andrew E. Bayly (2008), "Development of Surfactants and Builders in Detergent Formulations", Chinese Journal of Chemical Engineering, 16 (4): 517–527

- ↑ SNELL, FOSTER DEE (January 1959). "Syndets and Soaps". Industrial & Engineering Chemistry. 51 (1): 42A–46A. doi:10.1021/i650589a727.

- ↑ Dee, Foster; Snell, Cornelia T. (August 1958). "50th ANNIVERSARY FEATURE—Fifty Years of Detergent Progress". Industrial & Engineering Chemistry. 50 (8): 48A–51A. doi:10.1021/ie50584a005.

- ↑ Knud-Hansen, Chris (February 1994). "HISTORICAL PERSPECTIVE OF THE PHOSPHATE DETERGENT CONFLICT". www.colorado.edu. CONFLICT RESEARCH CONSORTIUM. Retrieved 21 March 2017.

- ↑ Kogawa, Ana Carolina; Cernic, Beatriz Gamberini; do Couto, Leandro Giovanni Domingos; Salgado, Hérida Regina Nunes (February 2017). "Synthetic detergents: 100 years of history". Saudi Pharmaceutical Journal. doi:10.1016/j.jsps.2017.02.006.

- ↑ Anne C. Steinemann, "Chemical Emissions from Residential Dryer Vents During Use of Fragranced Laundry Products", Air Quality, Atmosphere and Health, March 2013, Vol. 6, Issue 1, pp. 151–156.

External links

| Wikimedia Commons has media related to Laundry detergent. |

- Derbyshire, David (24 February 2008). "Don't bother with pre-wash (you're just wasting 6billion litres of water a year)". Mail Online. Retrieved 30 September 2010.

- About.com, Housewares/Appliances, What is HE Laundry Detergent & When are High-Efficiency Detergents Used by Mariette Mifflin

- Campbell tips for detergents chemistry, surfactants, and history related to laundry washing, destaining methods and soil.