Pneumatic tube

Pneumatic tubes (or capsule pipelines; also known as pneumatic tube transport or PTT) are systems that propel cylindrical containers through networks of tubes by compressed air or by partial vacuum.[1] They are used for transporting solid objects, as opposed to conventional pipelines, which transport fluids. Pneumatic tube networks gained acceptance in the late 19th and early 20th centuries for offices that needed to transport small, urgent packages (such as mail, paperwork, or money) over relatively short distances (within a building or, at most, within a city). Some installations grew to great complexity, but were mostly superseded. In some settings, such as hospitals, they remain widespread and have been further extended and developed in the 21st century.[2]

A small number of pneumatic transportation systems were also built for larger cargo, to compete with more standard train and subway systems. However, these never gained popularity.

History

Historical use

Pneumatic transportation was invented by William Murdoch around 1799.[3] The Victorians were the first to use capsule pipelines to transmit telegrams, to nearby buildings from telegraph stations. The system is known as pneumatic dispatch.[4]

In 1854 Josiah Latimer Clark was issued a patent "for conveying letters or parcels between places by the pressure of air and vacuum." In 1853 he installed a 220-yard (200 m) pneumatic system between the London Stock Exchange in Threadneedle Street, London, and the offices of the Electric Telegraph Company in Lothbury.[4] The Electric Telegraph Company used the system to acquire stock prices and other financial information to pass to subscribers of their service over their telegraph wires. The advantage of the pneumatic system was that without it the company would have had to employ runners to carry messages between the two buildings, or else employ trained telegraph operators within the Stock Exchange. In the mid-1860s, the company installed similar systems to local stock exchanges in Liverpool, Birmingham, and Manchester.[5] After the telegraphs were nationalised in Britain, the pneumatic system continued to be expanded under Post Office Telegraphs. By 1880 there were over 21 miles of tube in London.[6] A tube was laid between the Aberdeen fish market office and the head post office to facilitate the rapid sale of a very perishable commodity.[7]

While they are commonly used for small parcels and documents–including as cash carriers at banks or supermarkets[8]–they were originally proposed in the early 19th century for transport of heavy freight. It was once envisaged that networks of these massive tubes might be used to transport people.

Current use

The technology is still used on a smaller scale. While its use for communicating information has been superseded, pneumatic tubes are widely used for transporting small objects, where convenience and speed in a local environment are important.[2]

In the United States, drive-up banks often use pneumatic tubes to transport cash and documents between cars and tellers. Some U.S. hospitals have a computer-controlled pneumatic tube system to deliver drugs, documents and specimens to and from laboratories and nurses' stations.[2] Many factories use them to deliver parts quickly across large campuses. Many larger stores use systems to securely transport excess cash from checkout stands to back offices, and to send change back to cashiers.[9] NASA's original Mission Control Center had pneumatic tubes connecting controller consoles with staff support rooms.

Pneumatic tube systems are used in science, to transport samples during neutron activation analysis. Samples must be moved from the nuclear reactor core, in which they are bombarded with neutrons, to the instrument that records the resulting radiation. As some of the radioactive isotopes in the sample can have very short half-lives, speed is important. These systems may be automated, with a magazine of sample tubes that are moved into the reactor core in turn for a predetermined time, before being moved to the instrument station and finally to a container for storage and disposal.[10]

Until it closed in early 2011, a McDonald's in Edina, Minnesota claimed to be the "World's Only Pneumatic Air Drive-Thru," sending food from their strip-mall location to a drive-through in the middle of a parking lot.[11]

Technology editor Quentin Hardy notes that renewed interest in transmission of data by pneumatic tube accompanies discussions of digital network security,[12] and he cites research into London's forgotten pneumatic network.[13]

Applications

In postal service

Pneumatic post or pneumatic mail is a system to deliver letters through pressurized air tubes. It was invented by the Scottish engineer William Murdoch in the 19th century and was later developed by the London Pneumatic Despatch Company. Pneumatic post systems were used in several large cities starting in the second half of the 19th century (including an 1866 London system powerful and large enough to transport humans during trial runs – though not intended for that purpose),[14] but later were largely abandoned.

A major network of tubes in Paris was in use until 1984, when it was abandoned in favor of computers and fax machines. In Prague, in the Czech Republic, the network extended approximately 60 kilometres (37 mi).[15]

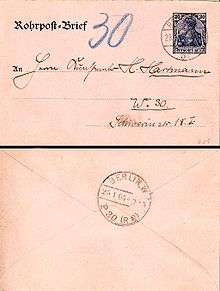

Pneumatic post stations usually connect post offices, stock exchanges, banks and ministries. Italy was the only country to issue postage stamps (between 1913 and 1966) specifically for pneumatic post. Austria, France, and Germany issued postal stationery for pneumatic use.

Typical applications are in banks, hospitals and supermarkets. Many large retailers used pneumatic tubes to transport cheques or other documents from cashiers to the accounting office.

- Historical use

- 1853: linking the London Stock Exchange to the city's main telegraph station (a distance of 220 yards (200 m) )

- 1861: in London with the London Pneumatic Despatch Company providing services from Euston railway station to the General Post Office and Holborn

- 1864: in Liverpool connecting the Electric and International Telegraph Company telegraph stations in Castle Street, Water Street and the Exchange Buildings[16]

- 1864: in Manchester to connect the Electric and International Telegraph Company central offices at York Street, with branch offices at Dulcie Buildings and Mosley Street[17]

- 1865: in Birmingham, installed by the Electric and International Telegraph Company between the New Exchange Buildings in Stephenson Place and their branch office in Temple Buildings, New Street.[18]

- 1865: in Berlin (until 1976), the Rohrpost, a system 400 kilometers in total length at its peak in 1940

- 1866: in Paris (until 1984, 467 kilometers in total length from 1934). John Steinbeck mentioned this system in The Short Reign of Pippin IV: A Fabrication: "You pay no attention to the pneumatique."

- 1871: in Dublin[19]

- 1875: in Vienna (until 1956)

- 1887: in Prague (until 2002 due to flooding), the Prague pneumatic post[20]

- 1893: the first North American system was established in Philadelphia by Postmaster General John Wanamaker, who had previously employed the technology at his department store. The system, which initially connected the downtown post offices, was later extended to the principal railroad stations, the stock exchanges, and many private businesses. It was operated by the United States Post Office Department which later opened similar systems in cities such as New York (connecting Brooklyn and Manhattan), Chicago, Boston, and St. Louis. The last of these closed in 1953.[21]

- Other cities: Munich, Rio de Janeiro, Buenos Aires, Hamburg, Rome, Naples, Milan, Marseille, Melbourne, Tokyo, Osaka, Nagoya, Kobe[22]

- 1950s-1989: CIA headquarters (now known as the Old Headquarters Building)[23]

In public transportation

- 19th century

In 1812, George Medhurst first proposed, but never implemented, blowing passenger carriages through a tunnel.[24] Precursors of pneumatic tube systems for passenger transport, the atmospheric railway (for which the tube was laid between the rails, with a piston running in it suspended from the train through a sealable slot in the top of the tube) were operated as follows:[25]

- 1844–54: Dublin and Kingstown Railway's Dalkey Atmospheric Railway between Kingstown (Dún Laoghaire) and Dalkey, Ireland (1.75 mi [2.82 km])

- 1846–47: London and Croydon Railway between Croydon and New Cross, London, England (7.5 mi [12.1 km])

- 1847–48: Isambard Kingdom Brunel's South Devon Railway between Exeter and Newton Abbot, England (20 mi [32 km])

- 1847–60: Paris–Saint-Germain railway between Bois de Vésinet and Saint-Germain-en-Laye, France (2 km [1.2 mi])

In 1861, the London Pneumatic Despatch Company built a system large enough to move a person, although it was intended for parcels. The inauguration of the new Holborn Station on 10 October 1865 was marked by having the Duke of Buckingham, the chairman, and some company directors blown through the tube to Euston (a five-minute trip).

The 550-metre (1,804 ft) Crystal Palace pneumatic railway was exhibited at the Crystal Palace in 1864. This was a prototype for a proposed Waterloo and Whitehall Railway that would have run under the River Thames linking Waterloo and Charing Cross. Digging commenced in 1865 but was halted in 1868 due to financial problems.

In 1867 at the American Institute Fair in New York, Alfred Ely Beach demonstrated a 100-foot (30 m) long, 6-foot (1.8 m) diameter pipe that was capable of moving 12 passengers plus a conductor.[26] In 1869, the Beach Pneumatic Transit Company of New York secretly constructed a 312-foot (95 m) long, 8.9-foot (2.7 m) diameter pneumatic subway line under Broadway, to demonstrate the possibilities of the new transport mode.[26] The line only operated for a few months, closing after Beach was unsuccessful in getting permission to extend it – Boss Tweed, a corrupt influential politician, did not want it to go ahead as he was intending to personally invest into competing schemes for an elevated rail line.[27]

- 20th century

In the 1960s, Lockheed and MIT with the United States Department of Commerce conducted feasibility studies on a vactrain system powered by ambient atmospheric pressure and "gravitational pendulum assist" to connect cities on the country's East Coast.[26] They calculated that the run between Philadelphia and New York City would average 174 meters per second, that is 626 km/h (388 mph). When those plans were abandoned as too expensive, Lockheed engineer L.K. Edwards founded Tube Transit, Inc. to develop technology based on "gravity-vacuum transportation". In 1967 he proposed a Bay Area Gravity-Vacuum Transit for California that would run alongside the then-under construction BART system. It was never built.

- 21st century

Research into trains running in partially evacuated tubes, such as the Vactrain and Hyperloop, is continuing.

In money transfer

In large retail stores, pneumatic tube systems were used to transport sales slips and money from the salesperson to a centralized tube room, where cashiers could make change, reference credit records, and so on.[28]

Many banks with drive-throughs also use pneumatic tubes to transfer input from customers to a teller.[8]

Some large corporations such as Costco have used pneumatic tubes in the past to transfer money from the food court to the main cashiers.

In medicine

Many hospitals have pneumatic tube systems which send samples to laboratories.[2][29] Blood preservations are transported, where weight and transport duration matter as well as preventing haemolysis caused by centrifugal and accelerating forces. Pneumatic tube systems are also used in hospitals to transport X-rays, patient documents, general documents, drugs and test results.

The 6-inch (152 mm) pneumatic tube system handle the heavy liter IV bags with significantly fewer jams compared to the 4-inch (102 mm) systems. Some pharmacies have unlisted tube station number(s) for the outbound station traffic. The pharmacy has limited outbound capacity with its published tube station, because the patient floors send vast numbers of prescriptions to the inbound tube station.[30]

In production

Pneumatic tube systems are used in production plants. Uses include conveying spare parts, measuring instruments, tools or work pieces alongside conveyor belts or in the production process. In industrial laboratories samples are transported through the pneumatic tube systems. These can be conveyed in any physical state (solid, liquid, gas) and at any temperature. For example, the industrial company ThyssenKrupp sends 900 °C (1,650 °F) steel samples through pneumatic tubes at a rate of 22 m (72 ft) per second from the furnace to the laboratory.[31]

Technical characteristics

Modern systems (for smaller, i.e. “normal”, tube diameters as used in the transport of small capsules) reach speeds of around 7.5 m (25 ft) per second, though some historical systems already achieved speeds of 10 m (33 ft) per second.[2][32] At the same time, varying air pressures allow capsules to brake slowly, removing the jarring arrival that used to characterise earlier systems and make them unsuitable for fragile contents.[2]

Very powerful systems can transport items with a weight of up to 50 kg (110 lb) and a diameter of up to 500 mm (20 in).[31] More than 100 lines and 1000 stations can be connected.

Further, modern systems can be computer-controlled for tracking of any specific capsule and managing priority deliveries as well as system efficiency. With this technology, time-critical items can be transported, such as tissue samples taken during a surgery in a hospital. RFID chips within in the capsules gather data – e. g. about the location of the carrier, its transport speed or its destination.[33] The systems collect and save these data to help users optimize their internal processes and turnaround times. The facilities can be linked to the company's software systems, e.g. laboratory information systems, for full integration into company logistical management and production chains.

See also

- Automated vacuum collection

- Lamson Engineering Company Ltd

- Pipeline transport

- Prague pneumatic post, the world's last preserved pneumatic mail system

- Vactrain

References

- Animation of Pneumatic tube

- "Gone with the wind: Tubes are whisking samples across hospital". Stanford School of Medicine. 2010-01-11. Retrieved 12 February 2010.

- Horst O. Hardenberg, The Middle Ages of the I.C. engine (Warrendale, 1999, 41)

- "Pneumatic Networks". Museum of Retrotechnology. 23 July 2008. Retrieved 4 January 2016.

- Kieve, Jeffrey L., The Electric Telegraph: A Social and Economic History, p. 82, David and Charles, 1973 OCLC 655205099.

- Kieve, p. 235

- Kieve, p. 237

- Buxton, Andrew (2004). Cash Carriers in Shops. Princes Risborough: Shire Publications. ISBN 978-0-7478-0615-8.

- "How pneumatic tube transport works". Explain that Stuff. Retrieved 2020-05-27.

- Becker, D.A. (22 June 1998). "Characterization and use of the new NIST rapid pneumatic tube irradiation facility". Journal of Radioanalytical and Nuclear Chemistry. 233 (1–2): 155–160. doi:10.1007/bf02389664.

- "Pneumatic Air Drive-Thru McDonald's". Waymarking website. Retrieved 12 February 2010.

- Hardy, Quentin (March 6, 2015). "The Mechanical World". What We're Reading. The New York Times. Retrieved March 7, 2015.

- "On The Blower: London's Lost Pneumatic Messaging Tubes". Lapsed Historian. February 14, 2015. Archived from the original on March 4, 2015. Retrieved March 7, 2015.

- Ian Steadman (18 December 2013). "London's Victorian Hyperloop: the forgotten pneumatic railway beneath the capital's streets". New Statesman. England. Retrieved 30 April 2019.

- "Czech start wins 19th century technology". Archived from the original on 27 November 2012. Retrieved 12 February 2010.

- "The Pneumatic Despatch Principle in Liverpool". Sheffield Daily Telegraph. England. 30 April 1864. Retrieved 14 February 2016 – via British Newspaper Archive.

- "Pneumatics applied to Telegraphy". Cumberland and Westmorland Advertiser, and Penrith Literary Chronicle. England. 13 December 1864. Retrieved 14 February 2016 – via British Newspaper Archive.

- "The Pneumatic Desptach System". Birmingham Daily Gazette. England. 1 March 1865. Retrieved 14 February 2016 – via British Newspaper Archive.

- "Postal Telegraph in Ireland". Clare Journal, and Ennis Advertiser. Ireland. 23 February 1871. Retrieved 14 February 2016 – via British Newspaper Archive.

- "Prague's pneumatic post". Telefónica O2 Czech Republic. 2002. Archived from the original on 2010-01-09. Retrieved 12 February 2010.

- Kyriakodis, Harry. "Pneumatic Philadelphia". Hidden City Philadelphia.

- Bush, Charles (April 2017). "Letters in a Tube: the Rise and Demise of Pneumatic Mail". History Magazine. 18 (4): 33.

- The CIA Museum ... Artifacts: Pneumatic-Tube Carrier

- George Medhurst, Calculations and remarks tending to prove the practicability ... of a plan for the rapid conveyance of goods and passengers upon an iron road through a tube of 30 feet in area, by the power and velocity of air, London: 1812

- Hadfield, Charles (1967). Atmospheric Railways. Newton Abbot: David & Charles. ISBN 0-7153-4107-3.

- Bellows, Alan. "The Remarkable Pneumatic People-Mover". www.damninteresting.com. Retrieved 4 January 2016.

- Allen, Oliver E. "New York's Secret Subway". AmericanHeritage.com website. Archived from the original on 16 February 2010. Retrieved 12 February 2010.

- Charles Augustus Sweetland, Department Store Accounts 1908, p. 70

- D. Hamill, Sean (2012-10-28). "UPMC constructing underground pneumatic tubes to link hospitals to new lab". Pittsburgh Post-Gazette. Retrieved 10 January 2016.

- "Archived copy" (PDF). Archived from the original (PDF) on 2019-01-02. Retrieved 2019-01-01.CS1 maint: archived copy as title (link)

- Schreibelmayer, Stefan (24 October 2012). "Hörtig schaut (gar nicht) in die Röhre". Wirtschaftsmagazin (in German) (10–2012). Nordbayerischer Kurier. p. 11. Retrieved 11 July 2018.

- "Capsule Pipelines – Mainland Europe". Capsu.org website. Archived from the original on 11 January 2010. Retrieved 12 February 2010.

- Fleet, Nadja (21 August 2017). "New Royal Adelaide Hospital: Futuristic NRAH features robots, state-of-the-art hi-tech equipment". The Advertiser. Retrieved 11 July 2018.

- M. Marcu-Pipeline conveyors(pneumatic wheeled pipeline conveyors-state of the art/photos-1990) at page 45 in the "Material handling in pyrometallurgy": proceedings of the International Symposium on Materials Handling in Pyrometallurgy, Hamilton, Ontario, August 26–30, 1990

- Twigge-Molecey, T. Price, Metallurgical Society of CIM. Non-Ferrous Pyrometallurgy Section Pergamon Press, Sep 30, 1990 - Technology & Engineering - 227 pages

External links

| Wikimedia Commons has media related to Pneumatic tube. |

- Site describing Pneumatic Trash and Linen Systems, with photos

- Describes Paris pneumatic post, also mentions others

- "Dial Switches Message Tubes" 1951 article that describes with photos and drawing the basics of how the system operates

- Site describing pneumatic post systems in England, France, Berlin, the US, and Prague, with photos

- Article describing the pneumatic post system in Prague

- Pneumatic mail article from the U.S. National Postal Museum

- The pneumatic dispatch... (1868) by Alfred Beach (scanned pages)

- Beach Pneumatic Alfred Beach's Pneumatic Subway and the beginnings of rapid transit in New York

- Futuristics: Pneumatic Transportation (contains historical illustrations)

- Capsule Pipelines: good historical information, original author of info found on "capsu.org" pages.

- Components of a pneumatic tube system

- Pneumatic Tube System Experts: Aerocom UK Limited - Nottingham

- Pneumatic Tube Transport developer: C.P.Bourg

- Archibald Williams, "Pneumatic Mail Tubes". Complete description and history in ordinary language. In The Romance of Modern Mechanism: With Interesting Descriptions in Non-Technical Language of Wonderful Machinery and Mechanical Devices and Marvellously Delicate Scientific Instruments, Etc., Etc. Philadelphia: Lippincott, 1907. Reprinted by Nabu Press, 2010. ISBN 1-146-99537-7.

- Pneumatic Tube System - How it works

- Cash Railway Website: pneumatic tubes used for cash handling in shops

- London Midland Magazine – February 1963 – article on the Pneumatic Dispatch Railway in London