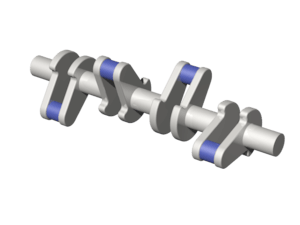

Crankpin

Crankpins highlighted in blue

A crankpin of a ship steam engine with the lubricating system visible

A crankpin or crank journal is a journal in an engine or mechanical device. That is, the part of a shaft or axle that rests on bearings.[1][2][3]

In a reciprocating engine, the crankpin is the part of a crankshaft where the lower end of a connecting rod attaches. In a beam engine, a single crankpin is mounted on the flywheel; In a steam locomotive, crankpins are often mounted directly on the driving wheels.

Application

A crankpin is separated from its shaft or axle by a bearing. These are commonly bushings or plain bearings, but less commonly may be roller bearings.

In a multi-cylinder engine, a crankpin can serve one or many cylinders, for example:

- In a in-line or opposed engine, each crankpin normally serves just one cylinder.

- In a V engine, each crankpin may serves one or two cylinders, depending on the design.

- In a radial engine, each crankpin serves an entire row of cylinders.

Design considerations

There are three common configurations in crankpin design:

- If a crankpin serves only one cylinder, then the big end (the usually larger end of a connecting rod that attaches to the crankpin, as opposed to the "small end", which is attached to the wrist/gudgeon pin in the piston, or the end of the crosshead in engines so equipped, allowing it to be articulated on both ends) is a relatively simple design, accommodating only one connecting rod. This design is the cheapest to produce, and is used in:

- All single-cylinder engines.

- Most straight engines.

- All boxer engines.

- Some V-twin engines.

- If a crankpin serves more than one cylinder, then the corresponding cylinders may have an offset, or may be articulated, to simplify the design of the big end bearing. This design is used in most V engines.

- If more than one cylinder is served by a single crankpin but there is no offset, then some or all of the connecting rods must be forked at the big end, or be articulated. This design provides better engine balance than designs with an offset, but requires extra complexity and cost in both design and manufacture, and more weight or closer manufacturing tolerances to achieve the same strength and reliability. Any extra weight added to the big end itself also carries a penalty of adding vibration and reducing balance. As the number of cylinders grows, the effect of the offset on balance becomes less important, and forked connecting rods become less common. They are mainly used in V-twin engines, notably including motorcycle engines, but in the past were found on a number of automobile and aero engines, such as the famous Rolls-Royce Merlin aero engine of the WWII era.

- Articulated rods were used in older or exotic Vee engines, and consist of rods that have a single master connecting rod attached to the crank pin, with the opposing connecting rod (sometimes two) instead using a smaller bearing machined into the big end of the main connecting rod, instead of two dedicated crank journals.

- A similar but more complex design is used in radial engines, which have a master/slave connecting rod, with a single "master" connecting rod attached to the single crankpin (one for each row in multi-row designs), and smaller bearings for each of the corresponding cylinders machined into the big end of the master rod. For more detail see the article on radial engines.

See also

References

- ↑ "the definition of crankpin". Dictionary.com. Retrieved 2018-02-05.

- ↑ "Crankpin". www.wartsila.com. Retrieved 2018-02-05.

- ↑ "Crankpin definition and meaning | Collins English Dictionary". www.collinsdictionary.com. Retrieved 2018-02-05.

This article is issued from

Wikipedia.

The text is licensed under Creative Commons - Attribution - Sharealike.

Additional terms may apply for the media files.