Coachbuilder

A coachbuilder is a manufacturer of bodies for passenger-carrying vehicles.[note 1] Coachwork is the body of an automobile or a bus or a horse-drawn passenger vehicle. The word "coach" was derived from the Hungarian town of Kocs.[1] By extension, "coach" also may be used for a railroad passenger car or railway carriage.

Custom or bespoke bodies require a rolling chassis to avoid the vast expense of designing and building a suitable unibody or monocoque structure. While the enormous cost of suitable machinery to make steel structures may be avoided by moulding synthetic materials for one-off bodies the high costs of structural design and development remain prohibitively expensive.

As well as true custom or bespoke bodies, coachbuilders also made short runs of more-or-less identical bodies to the order of dealers or the manufacturer of a chassis. The same body design might then be adjusted to suit different brands of chassis. Examples include Salmons & Sons' Tickford bodies with a patent device to raise or lower a convertible's roof, used on their 19th century carriages, or Wingham convertible bodies by Martin Walter.

Custom body is the standard term in North American English. Coachbuilders are: carrossiers in French, carrozzeria in Italian, Karosseriebauer in German and carroceros in Spanish.

Coach-built implies that a body's frame is wooden, but it may not be so. Coachbuilt also describes a recreational vehicle or motorhome that has been purpose-built. A whole new body has been made for a bare chassis, as opposed to a conversion built inside an existing vehicle body.

Before automobiles

.jpg)

A British trade association the Worshipful Company of Coachmakers and Coach Harness Makers, was incorporated in 1630. Some British coachmaking firms operating in the 20th century were established even earlier. Rippon was active in the time of Queen Elizabeth I, Barker founded in 1710 by an officer in Queen Anne's Guards, Brewster a relative newcomer (though oldest in the U.S.), formed in 1810.[2]

Early production

In the early motoring days, when series production did not yet exist, the process of acquiring a new vehicle needed two major decisions — selection of a vehicle manufacturer and selection of a coachbuilder. Already accustomed to ordering carriages from a coachbuilder, the buyer would select an automobile manufacturer, which might supply their own catalogued bodies, but who would be expected to provide primarily only a bare "chassis".

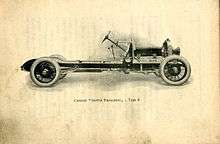

This "chassis" would be delivered by the manufacturer to the coachbuilder of the buyer's choice. It would be a rolling chassis, which included the chassis frame, drivetrain (engine, gearbox, differential, axles, wheels), brakes, suspension, complete steering system, including the wheel, radiator, scuttle and dashboard. The manufacturer delivered the chassis with lighting system, spare wheel(s), but probably without tyres, front and rear mudguards and (later) bumpers. The very easily damaged honeycomb radiator, later enclosed and protected by a shell, became the main visual element identifying the chassis' brand. The manufacturer retained an element of control over bodies. Bodies not approved by the chassis manufacturer would lose the chassis manufacturer's chassis warranties.

Until World War II it would not have been unusual to order the most popular cars as only a chassis and have a local coachbuilder put a body (passenger or commercial) on it. the Austin 7s of the 1920s and 1930s were favourite subjects.

For mass production, because the long-established and refined skills and tools (such as the English wheel) used to build the wooden and metal bodies of vehicles were so specialized, most automobile manufacturers in the United States contracted with existing coachbuilders to produce bodies. For example, Fisher Body built all of Cadillac's closed bodies in the 1910s and eventually all General Motors mass-produced products.

Ultra luxury vehicles

When popular automobile manufacturers brought body building skills in-house, the practice of bespoke or custom coachbuilding remained in favour among the wealthy, who continued the habit of centuries past. Commonly, larger dealers or distributors of ultra-luxury cars would pre-order stock chassis and the bodies they thought most likely to sell, and stock them in suitable quantities for sale off their showroom floor.

All ultra-luxury vehicles of automobiling's Golden Era before World War II sold as chassis only. For instance, when Duesenberg introduced their Model J, it was offered as chassis only, for $8,500. Other examples include the Bugatti Type 57, Cadillac V-16, Ferrari 250, Isotta Fraschini Tipo 8, and all Rolls-Royces produced before World War II. Delahaye had no in-house coachworks, so all its chassis were bodied by independents, who created some of their most attractive designs on the Type 135. Most of the Delahayes were bodied by Chapron, Labourdette, Franay, Saoutchik, Figoni & Falaschi, Pennock, and many more carrossiers.

The practice remained in limited force after World War II, with both luxury chassis and high-performance sports cars and gran turismos, waning dramatically by the late 1960s. Even Rolls-Royce acquiesced, debuting its first unibody model, the Silver Shadow, in 1965, before taking all R-R and Bentley bodying in-house.

Unibody construction

The advent of unibody construction, where the car body is unified with, and structurally integral to the chassis, made custom coachbuilding uneconomic. Many coachbuilders closed down, were bought by manufacturers or changed their core business to other activities:

- Transforming into dedicated design or styling houses, subcontracting to automotive brands (e.g. Zagato, Frua, Bertone, Pininfarina)

- Transforming into general coachwork series manufacturers, subcontracting to automotive brands (e.g. Karmann, Bertone, Vignale, Pininfarina)

- Manufacturing runs of special coachworks for trucks, delivery vans, touringcars, ambulances, fire engines, public transport vehicles, etc. (e.g. Pennock, Van Hool, Plaxton, Heuliez)

- Becoming technical partner for development of e.g. roof constructions (e.g. Karmann, Heuliez) or producer of various (aftermarket) automotive parts (e.g. Giannini)

Independent coachbuilders survived for a time after the mid-20th century, making bodies for the chassis produced by low-production companies such as Rolls-Royce, Ferrari, and Bentley.[3] Producing body dies is extremely expensive (a single door die can run to US$40,000), which is usually only considered practical when large numbers are involved—though that was the path taken by Rolls-Royce and Bentley after 1945 for their own in-house production. Because dies for pressing metal panels are so costly, from the mid 20th century, many vehicles, most notably the Chevrolet Corvette, were clothed with large panels of fiberglass reinforced resin, which only require inexpensive molds. Glass has since been replaced by more sophisticated materials, if necessary hand-formed. Generally these replace metal only where weight is of paramount importance.

Gallery

Examples of custom coachwork on rolling chassis, and unibody modifications:

Pourtout drophead coupé on a Lancia Belna chassis 1935

Pourtout drophead coupé on a Lancia Belna chassis 1935 Fixed head coupé by Ghia 1954 on an Alfa Romeo 1900 SS chassis

Fixed head coupé by Ghia 1954 on an Alfa Romeo 1900 SS chassis Touring 2-seater body 1952 on an Alfa Romeo 6C 2300B chassis

Touring 2-seater body 1952 on an Alfa Romeo 6C 2300B chassis Hebmüller-cabriolet on a unibody Volkswagen chassis

Hebmüller-cabriolet on a unibody Volkswagen chassis

List of coachbuilders

Belgium

France

Germany

Indonesia

- Adiputro wirasejati

- Rahayu Santosa

- Tentrem

- Laksana Karoseri

- Restu Ibu Pusaka

- Morodadi Prima

- New Armada

- Trisakti

- Cipta Karya

Italy

Japan

Switzerland

United Kingdom

- Abbey

- Abbott

- Barker

- Carbodies

- Carlton

- Crayford Engineering

- Charlesworth

- Corsica

- Croall

- Cunard

- Gordon England

- Freestone and Webb

- Grose

- J Gurney Nutting & Co Limited

- Harrington

- Hooper

- Jarvis of Wimbledon

- Jensen

- Hoyal

- Lancefield

- Martin Walter

- Arthur Mulliner

- H. J. Mulliner & Co.

- Mulliner Park Ward

- Mulliners (Birmingham)

- Nu-Track

- Park Ward

- Harold Radford

- Salmons

- Swallow

- Tickford

- Thrupp & Maberly

- Vanden Plas

- Vince & Son

- Vincent of Reading

- Wingham Martin Walter

- Wrightbus

- James Young

United States

- Abbot-Downing Company

- Biddle and Smart

- Bohman & Schwartz

- Brewster & Co.

- Briggs Manufacturing Company

- Brunn & Company

- Budd Company

- Darrin of Paris

- Derham

- Dietrich Inc.

- Earl Automobile Works

- Fisher

- Albert Fisher (Detroit)

- Fleetwood

- Holbrook Company

- John B Judkins Company

- LeBaron

- Rollston

- SSZ Motorcars

- Walker Body Company

- Waterhouse Company

- Willoughby Company

- Wilson Body Company

Survivors of the unibody production-line system

See also

Notes

- ↑ Construction has always been a skilled trade requiring a relatively lightweight product with sufficient strength. The manufacture of necessarily fragile, but satisfactory wheels by a separate trade, a wheelwright, held together by iron or steel tyres, was always most critical.

The word coachbuilder is recorded as early as 1794. From about AD 1000, rougher work was carried out by a wainwright, a wagon-builder. Later names are cartwright, a carpenter who makes carts, also (from 1587);coachwright; (starting in 1599) coachmaker. Subtrades include wheelwright, coachjoiner, etc. Oxford English Dictionary 2011

Citations

- ↑ Coach. Oxford English Dictionary (1st ed.). Oxford University Press. 1933.

- ↑ G.N. Georgano, G. N. Cars: Early and Vintage, 1886-1930. (London: Grange-Universal, 1990), p.206

- ↑ "Steel Bodies: In an Eggshell", in Ward, Ian, executive editor. World of Automobiles (London: Orbis Publishing, 1974), p. 2178.

- ↑ Coway web site Archived 2012-04-24 at the Wayback Machine.

- ↑ Jankel web site Archived 2012-04-05 at the Wayback Machine.

- ↑ "Wheelchair Accessible Vehicles, Mobility Cars, Disability Car, Adapted Vehicles for Sale". jubileemobility.co.uk.

- ↑ "Specialist Vehicle Converter & Supplier - MacNeillie". MacNeillie.

- ↑ "Hearse for Sale - Limousine for Sale - Wilcox Limousines". Wilcox Limousines.

- ↑ "Woodall Nicholson". woodall-nicholson.co.uk.

External links

| Wikimedia Commons has media related to Coachbuilders. |

| Wikimedia Commons has media related to Coachbuilder badges. |

- Coachbuild.com: Encyclopedia of worldwide Coachbuilders from past to present

- Encyclopedia of American Coachbuilders

- Goldarths: The Fine Art of Coachbuilding

- The Kellner Affair: Matters of Life and Death by Peter M. Larsen and Ben Erickson. Details Jacques Kellner and George Paulin involvement in the French Resistance.