Chlorella vulgaris

| Chlorella vulgaris | |

|---|---|

| |

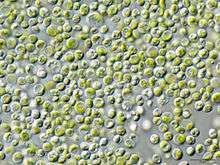

| Chlorella vulgaris on microscope view | |

| Scientific classification | |

| (unranked): | Viridiplantae |

| Class: | Trebouxiophyceae |

| Order: | Chlorellales |

| Family: | Chlorellaceae |

| Genus: | Chlorella |

| Species: | C. vulgaris |

| Binomial name | |

| Chlorella vulgaris Beijerinck 1890 | |

| Varieties | |

| |

| Synonyms[1] | |

| |

Chlorella vulgaris is a green microalgae mainly used as a medical treatment in Japan. It thought to have potential for biofuel production or as a food additive.

Introduction

C. vulgaris is a green eukaryotic microalgae in the genus Chlorella, which has been present on earth since the Precambrian period.[2] This unicellular algae was discovered in 1890 by Martinus Willem Beijerinck as the first microalgae with a well-defined nucleus.[3] At the beginning of the 1990s, German scientists noticed the high protein content of C. vulgaris and began to consider it as a new food source. Japan is currently the largest consumer of Chlorella, mostly because of its medical properties.[4][2]

Production

The world annual production of the various species of Chlorella was 2000t (dry weight) in 2009, with the main producers being Germany, Japan and Taiwan.[2] C. vulgaris constitutes an excellent candidate for production due to its high resistance against rough conditions and invading organisms. In addition, the production of the various organic macromolecules of interest (proteins, lipids, starch) differ depending on the technique used to create biomass and can be therefore targeted.[2] Under more hostile conditions, the biomass decreases but lipids and starch contents increase.[5] Under favourable conditions, protein content raises along with the biomass.[6] Different growth techniques have been developed. They exploit the autotrophic, heterotrophic or mixotrophic properties of C. vulgaris. Growing C. vulgaris autotrophically is illustrated by the closed photo-bioreactor. Harvesting the biomass is then generally done by centrifugation due to the high process efficiency (95% recovery). Other techniques exist as well, such as flocculation, filtration,[7] flotation.[8]

Uses

Bioenergy

C. vulgaris is seen as a promising source of bioenergy. It may be a good alternative to the current biofuel crops, like soybean, corn or rapeseed, as it is more productive and do not compete with food production.[9] It can produce large amount of lipids, up to 20 times more than crop,[10] which have a suitable profile for biodiesel production.[11] This microalgae also contains high amount of starch, good enough for the production of bioethanol.[2] However, microalgal biofuels are still far from being competitive with fossil fuels, regarding their high production costs and controversial sustainability.[2]

Food and health

The proteins content of C. Vulgaris varies from 42 to 58% of its biomass dry weight.[12][13][14][15][16] These proteins are considered as having a good nutritional quality compared to the standard profile for human nutrition of the World Health Organisation and Food and Agricultural Organisation, as the algae synthesise essential and non-essential amino-acids.[2] The algae also contains lipids (5-40% of the dry mass),[12] carbohydrates (12-55% dry weight)[17][18] and pigments with among others chlorophyll, reaching 1-2 % of the dry weight.[19][20] C. vulgaris contains also some minerals and vitamins important for human nutrition.[2] C. vulgaris is marketed as dietary supplement, additive,[21][22] as colourant or food emulsion.[23] They are all in the form of capsules, extracts, tablets or powder.[24][25] They are consumed in Japan as a medical treatment.[4][26] C. vulgaris has demonstrated some antitumor and immune-modulating characteristics.[27][28][29][30][31] However, despite its high nutritious protein content and its potentially health benefits, C. vulgaris is not yet widely incorporated in food products. The main reason for this is its dark green colour and its smell, which is close to that of fish.[32]

References

- ↑ "Chlorella vulgaris". NCBI taxonomy. Bethesda, MD: National Center for Biotechnology Information. Retrieved 5 December 2017.

Other names: synonym: Chlorella vulgaris var. viridis Chodat includes: Chlorella vulgaris Beijerink IAM C-27 formerly Chlorella ellipsoidea Gerneck IAM C-27

- 1 2 3 4 5 6 7 8 Safi, C., Zebib, B., Merah, O., Pontalier, P. Y., & Vaca-Garcia, C. (2014). Morphology, composition, production, processing and applications of Chlorella vulgaris: A review. Renewable & Sustainable Energy Reviews, 35, 265-278. doi: 10.1016/j.rser.2014.04.007

- ↑ Beijerinck, M. W. (1890). Culturversuche mit Zoochlorellen, Lichenengonidien und anderen niederen Algen. Bot. Zeitung, 48, 781-785.

- 1 2 Kitada, K., Machmudah, S., Sasaki, M., Goto, M., Nakashima, Y., Kumamoto, S., & Hasegawa, T. (2009). Supercritical CO2 extraction of pigment components with pharmaceutical importance from Chlorella vulgaris. Journal of chemical technology and biotechnology, 84(5), 657-661.

- ↑ Pribyl, P., Cepak, V., & Zachleder, V. (2012). Production of lipids in 10 strains of Chlorella and Parachlorella, and enhanced lipid productivity in Chlorella vulgaris. Appl Microbiol Biotechnol, 94(2), 549-561. doi:10.1007/s00253-012-3915-5

- ↑ Chisti, Y. (2007). Biodiesel from microalgae. Biotechnol Adv, 25(3), 294-306. doi:10.1016/j.biotechadv.2007.02.001

- ↑ Lee, D. J., Liao, G. Y., Chang, Y. R., & Chang, J. S. (2012). Coagulation-membrane filtration of Chlorella vulgaris. Bioresour Technol, 108, 184-189. doi:10.1016/j.biortech.2011.12.098

- ↑ Cheng, Y. L., Juang, Y. C., Liao, G. Y., Ho, S. H., Yeh, K. L., Chen, C. Y., . . . Lee, D. J. (2010). Dispersed ozone flotation of Chlorella vulgaris. Bioresour Technol, 101(23), 9092-9096. doi:10.1016/j.biortech.2010.07.016

- ↑ Singh, A., Nigam, P. S., & Murphy, J. D. (2011). Renewable fuels from algae: An answer to debatable land based fuels. Bioresource Technology, 102(1), 10-16. doi: 10.1016/j.biortech.2010.06.032

- ↑ Demirbas, M. F. (2011). Biofuels from algae for sustainable development. Applied Energy, 88(10), 3473-3480. doi: https://doi.org/10.1016/j.apenergy.2011.01.059

- ↑ Wang, K. G., Brown, R. C., Homsy, S., Martinez, L., & Sidhu, S. S. (2013). Fast pyrolysis of microalgae remnants in a fluidized bed reactor for bio-oil and biochar production. Bioresource Technology, 127, 494-499. doi: 10.1016/j.biortech.2012.08.016

- 1 2 Becker, E. W. (1994). Microalgae: biotechnology and microbiology (Vol. 10): Cambridge University Press.

- ↑ Morris, H. J., Almarales, A., Carrillo, O., & Bermúdez, R. C. (2008). Utilisation of Chlorella vulgaris cell biomass for the production of enzymatic protein hydrolysates. Bioresource technology, 99(16), 7723-7729.

- ↑ Safi, C., Charton, M., Pignolet, O., Silvestre, F., Vaca-Garcia, C., & Pontalier, P.-Y. (2013). Influence of microalgae cell wall characteristics on protein extractability and determination of nitrogen-to-protein conversion factors. Journal of applied phycology, 25(2), 523-529.

- ↑ Servaites, J. C., Faeth, J. L., & Sidhu, S. S. (2012). A dye binding method for measurement of total protein in microalgae. Analytical biochemistry, 421(1), 75-80.

- ↑ Seyfabadi, J., Ramezanpour, Z., & Khoeyi, Z. A. (2011). Protein, fatty acid, and pigment content of Chlorella vulgaris under different light regimes. Journal of applied phycology, 23(4), 721-726.

- ↑ Brányiková, I., Maršálková, B., Doucha, J., Brányik, T., Bišová, K., Zachleder, V., & Vítová, M. (2011). Microalgae—novel highly efficient starch producers. Biotechnology and bioengineering, 108(4), 766-776.

- ↑ Choix, F. J., de-Bashan, L. E., & Bashan, Y. (2012). Enhanced accumulation of starch and total carbohydrates in alginate-immobilized Chlorella spp. induced by Azospirillum brasilense: II. Heterotrophic conditions. Enzyme and microbial technology, 51(5), 300-309.

- ↑ de-Bashan, L. E., Bashan, Y., Moreno, M., Lebsky, V. K., & Bustillos, J. J. (2002). Increased pigment and lipid content, lipid variety, and cell and population size of the microalgae Chlorella spp. when co-immobilized in alginate beads with the microalgae-growth-promoting bacterium Azospirillum brasilense. Canadian Journal of Microbiology, 48(6), 514-521.

- ↑ Gonzalez, L. E., & Bashan, Y. (2000). Increased growth of the microalga chlorella vulgariswhen coimmobilized and cocultured in alginate beads with the plant-growth-promoting bacterium Azospirillum brasilense. Applied and Environmental Microbiology, 66(4), 1527-1531.

- ↑ Fradique, M., Batista, A. P., Nunes, M. C., Gouveia, L., Bandarra, N. M., & Raymundo, A. (2010). Incorporation of Chlorella vulgaris and Spirulina maxima biomass in pasta products. Part 1: Preparation and evaluation. Journal of the Science of Food and Agriculture, 90(10), 1656-1664.

- ↑ Li, H.-B., Jiang, Y., & Chen, F. (2002). Isolation and purification of lutein from the microalga Chlorella vulgaris by extraction after saponification. Journal of agricultural and food chemistry, 50(5), 1070-1072.

- ↑ Fernandes, B., Dragone, G., Abreu, A. P., Geada, P., Teixeira, J., & Vicente, A. (2012). Starch determination in Chlorella vulgaris—a comparison between acid and enzymatic methods. Journal of applied phycology, 24(5), 1203-1208.

- ↑ Liang, S., Liu, X., Chen, F., & Chen, Z. (2004). Current microalgal health food R & D activities in China. Asian Pacific Phycology in the 21st Century: Prospects and Challenges, 45-48.

- ↑ Yamaguchi, K. (1996). Recent advances in microalgal bioscience in Japan, with special reference to utilization of biomass and metabolites: a review. Journal of applied phycology, 8(6), 487-502.

- ↑ Morris, H. J., Carrillo, O. V., Almarales, Á., Bermúdez, R. C., Alonso, M. E., Borges, L., Quintana, M. M., Fontaine, R., Llauradó, G., & Hernández, M. (2009). Protein hydrolysates from the alga Chlorella vulgaris 87/1 with potentialities in immunonutrition. Biotecnología Aplicada, 26(2), 162-165.

- ↑ Justo, G. Z., Silva, M. R., & Queiroz, M. L. S. (2001). Effects of the green algae Chlorella vulgaris on the response of the host hematopoietic system to intraperitoneal Ehrlich ascites tumor transplantation in mice. Immunopharmacology and Immunotoxicology, 23(1), 119-132. doi:10.1081/iph-100102573

- ↑ Konishi, F., Tanaka, K., Himeno, K., Taniguchi, K., & Nomoto, K. (1985). Antitumor effect induced by a hot water extract of Chlorella vulgaris (CE): resistance to Meth-A tumor growth mediated by CE-induced polymorphonuclear leukocytes. Cancer Immunology, Immunotherapy, 19(2), 73-78.

- ↑ Morimoto, T., Nagatsu, A., Murakami, N., Sakakibara, J., Tokuda, H., Nishino, H., & Iwashima, A. (1995). Anti-tumour-promoting glyceroglycolipids from the green alga, Chlorella vulgaris. Phytochemistry, 40(5), 1433-1437.

- ↑ Singh, A., Singh, S., & Bamezai, R. (1999). Inhibitory potential of Chlorella vulgaris (E-25) on mouse skin papillomagenesis and xenobiotic detoxication system. Anticancer research, 19(3A), 1887-1891.

- ↑ Yasukawa, K., Akihisa, T., Kanno, H., Kaminaga, T., Izumida, M., Sakoh, T., Tamura, T., & Takido, M. (1996). Inhibitory effects of sterols isolated from Chlorella vulgaris on 12-O-tetradecanoylphorbol-13-acetate-induced inflammation and tumor promotion in mouse skin. Biological and Pharmaceutical Bulletin, 19(4), 573-576.

- ↑ Becker, E. (2007). Micro-algae as a source of protein. Biotechnology advances, 25(2), 207-210.