Offshore wind power

Offshore wind power or offshore wind energy is the use of wind farms constructed in bodies of water, usually in the ocean, to harvest wind energy to generate electricity. Higher wind speeds are available offshore compared to on land, so offshore wind power’s electricity generation is higher per amount of capacity installed,[1] and NIMBY opposition to construction is usually much weaker.

Unlike the typical use of the term "offshore" in the marine industry, offshore wind power includes inshore water areas such as lakes, fjords and sheltered coastal areas as well as deeper-water areas. Most offshore wind farms employ fixed-foundation wind turbines in relatively shallow water. As of 2020, floating wind turbines for deeper waters are in the early phase of development and deployment.

At the end of 2017, the total worldwide offshore wind power capacity was 18.8 gigawatt (GW).[2] All the largest offshore wind farms are currently in northern Europe, especially in the United Kingdom and Germany, which together account for over two-thirds of the total offshore wind power installed worldwide. As of September 2018, the 659 MW Walney Extension in the United Kingdom is the largest offshore wind farm in the world.[3] The Hornsea Wind Farm under construction in the United Kingdom will become the largest when completed, at 1,200 MW. Other projects are in the planning stage, including Dogger Bank in the United Kingdom at 4.8 GW, and Greater Changhua in Taiwan at 2.4 GW.[4]

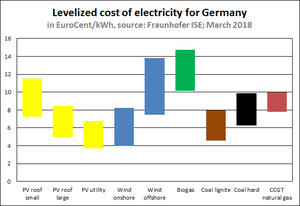

The cost of offshore wind power has historically been higher than that of onshore wind generation,[5] but costs have been decreasing rapidly in recent years to $78/MWh in 2019.[6] Offshore wind power in Europe has been price-competitive with conventional power sources since 2017.[7]

History

.jpg)

Europe is the world leader in offshore wind power, with the first offshore wind farm (Vindeby) being installed in Denmark in 1991.[12] In 2009, the average nameplate capacity of an offshore wind turbine in Europe was about 3 MW, and the capacity of future turbines was expected to increase to 5 MW.[12]

In 2010, the US Energy Information Agency said "offshore wind power is the most expensive energy generating technology being considered for large scale deployment".[5] The 2010 state of offshore wind power presented economic challenges significantly greater than onshore systems, with prices in the range of 2.5-3.0 million Euro/MW.[13] That year, Siemens and Vestas were turbine suppliers for 90% of offshore wind power, while DONG Energy, Vattenfall and E.on were the leading offshore operators.[1]

In 2011, DONG Energy estimated that while offshore wind turbines were not yet competitive with fossil fuels, they would be in 15 years. Until then, state funding and pension funds would be needed.[14] At the end of 2011, there were 53 European offshore wind farms in waters off Belgium, Denmark, Finland, Germany, Ireland, the Netherlands, Norway, Sweden and the United Kingdom, with an operating capacity of 3,813 MW,[15] while 5,603 MW was under construction.[16] Offshore wind farms worth €8.5 billion ($11.4 billion) were under construction in European waters in 2011.[17]

In 2012, Bloomberg estimated that energy from offshore wind turbines cost €161 (US$208) per MWh.[18]

A 2013 comprehensive review of the engineering aspects of turbines like the sizes used onshore, including the electrical connections and converters, considered that the industry had in general been overoptimistic about the benefits-to-costs ratio and concluded that the "offshore wind market doesn’t look as if it is going to be big".[19][20] In 2013, offshore wind power contributed to 1,567 MW of the total 11,159 MW of wind power capacity constructed that year.[21]

By January 2014, 69 offshore wind farms had been constructed in Europe with an average annual rated capacity of 482 MW.[22] The total installed capacity of offshore wind farms in European waters reached 6,562 MW.[22] The United Kingdom had by far the largest capacity with 3,681 MW. Denmark was second with 1,271 MW installed and Belgium was third with 571 MW. Germany came fourth with 520 MW, followed by the Netherlands (247 MW), Sweden (212 MW), Finland (26 MW), Ireland (25 MW), Spain (5 MW), Norway (2 MW) and Portugal (2 MW).[22]

At the end of 2015, 3,230 turbines at 84 offshore wind farms across 11 European countries had been installed and grid-connected, making a total capacity of 11,027 MW.[23][24]

Outside of Europe, the Chinese government had set ambitious targets of 5 GW of installed offshore wind capacity by 2015 and 30 GW by 2020 that would eclipse capacity in other countries. However, in May 2014 the capacity of offshore wind power in China was only 565 MW.[25] Offshore capacity in China increased by 832 MW in 2016, of which 636 MW were made in China.[26]

The offshore wind construction market remains quite concentrated. By the end of 2015, Siemens Wind Power had installed 63% of the world's 11 GW[27] offshore wind power capacity; Vestas had 19%, Senvion came third with 8% and Adwen 6%.[28][2] About 12 GW of offshore wind power capacity was operational, mainly in Northern Europe, with 3,755 MW of that coming online during 2015.[29]

Costs of offshore wind power are decreasing much faster than expected. By 2016, four contracts (Borssele and Kriegers) were already below the lowest of the predicted 2050 prices.[30][31]

Future development

Projections for 2020 estimate an offshore wind farm capacity of 40 GW in European waters, which would provide 4% of the European Union's demand of electricity.[32] The European Wind Energy Association has set a target of 40 GW installed by 2020 and 150 GW by 2030.[12] Offshore wind power capacity is expected to reach a total of 75 GW worldwide by 2020, with significant contributions from China and the United States.[1]

The Organisation for Economic Co-operation and Development (OECD) predicted in 2016 that offshore wind power will grow to 8% of ocean economy by 2030, and that its industry will employ 435,000 people, adding $230 billion of value.[33]

Types of offshore wind turbines

Fixed foundation offshore wind turbines

Almost all currently operating offshore wind farms employ fixed foundation turbines, with the exception of a few pilot projects. Fixed foundation offshore wind turbines have fixed foundations underwater, and are installed in relatively shallow waters of up to 50–60 m.[34]

Types of underwater structures include monopile, tripod, and jacketed, with various foundations at the sea floor including monopile or multiple piles, gravity base, and caissons.[34] Offshore turbines require different types of bases for stability, according to the depth of water. To date a number of different solutions exist:[12][35]

- Most foundations are monopile (single column) base, six meters in diameter, is used in waters up to 30 meters deep.

- Conventional steel jacket structures, as used in the oil and gas industry, in water 20–80 m deep.

- Gravity base structures, for use at exposed sites in water 20–80 m deep.

- Tripod piled structures, in water 20–80 m deep.

- Tripod suction caisson structures, in water 20–80 m deep.

Monopiles up to 11 m diameter at 2,000 tonnes can be made, but the largest so far are 1,300 tons which is below the 1,500 tonnes limit of some crane vessels. The other turbine components are much smaller.[36]

The tripod pile substructure system is a new concept developed to reach deeper waters than with the shallow water systems, up to 60 m. This technology consists of three monopiles linked together through a joint piece at the top. The main advantage of this solution is the simplicity of the installation, which is done by installing three monopiles and then adding the upper joint.[37]

Tripod is an innovative concept that consists on a central pipe that lies on a tripod tubular frame configuration at its bottom part. This uses three small seabed driven piles at each leg of the tripod to link it to the seabed. The main advantage of the tripod system is that it has a larger base, which decreases its risk of getting overturned. Due to the large dimensions the installation process is more difficult and increases the cost.[37]

A steel jacket structure comes from an adaptation to the offshore wind industry of concepts that have been in use in the oil and gas industry for decades. Their main advantage lies in the possibility of reaching higher depths (up to 80m). Their main limitations are due to the high construction and installation costs.[37]

Floating offshore wind turbines

For locations with depths over about 60–80 m, fixed foundations are uneconomical or technically unfeasible, and floating wind turbine anchored to the ocean floor are needed.[38][39][40] Hywind is the world's first full-scale floating wind turbine, installed in the North Sea off Norway in 2009.[41] Hywind Scotland, commissioned in October 2017, is the first operational floating wind farm, with a capacity of 30 MW. Other kinds of floating turbines have been deployed, and more projects are planned.

Vertical axis offshore wind turbines

Although the great majority of onshore and all large-scale offshore wind turbines currently installed are horizontal axis, vertical axis wind turbines have been proposed for use in offshore installations. Thanks to the installation offshore and their lower center of gravity, these turbines can in principle be built bigger than horizontal axis turbines, with proposed designs of up to 20 MW capacity per turbine.[42] This could improve the economy of scale of offshore wind farms.[42] However, there are no current large-scale demonstrations of this technology.

Economics

The advantage of locating wind turbines offshore is that the wind is much stronger off the coasts, and unlike wind over the continent, offshore breezes can be strong in the afternoon, matching the time when people are using the most electricity. Offshore turbines can also be located close to the load centers along the coasts, such as large cities, eliminating the need for new long-distance transmission lines.[44] However, there are several disadvantages of offshore installations, related to more expensive installation, difficulty of access, and harsher conditions for the units.

Locating wind turbines offshore exposes the units to high humidity, salt water and salt water spray which negatively affect service life, cause corrosion and oxidation, increase maintenance and repair costs and in general make every aspect of installation and operation much more difficult, time-consuming, more dangerous and far more expensive than sites on land. The humidity and temperature is controlled by air conditioning the sealed nacelle.[45] Sustained high-speed operation and generation also increases wear, maintenance and repair requirements proportionally.

The cost of the turbine represents just one third to one half[13] of total costs in offshore projects today, the rest comes from infrastructure, maintenance, and oversight. Costs for foundations, installation, electrical connections and operation and maintenance (O&M) are a large share of the total for offshore installations compared to onshore wind farms. The cost of installation and electrical connection also increases rapidly with distance from shore and water depth.[42]

Other limitations of offshore wind power are related to the still limited number of installations. The offshore wind industry is not yet fully industrialized, as supply bottlenecks still exist as of 2017.[46]

Investment costs

Offshore wind farms tend to have larger turbines when compared to onshore installations, and the trend is towards a continued increase in size. Economics of offshore wind farms tend to favor larger turbines, as installation and grid connection costs decrease per unit energy produced.[42] Moreover, offshore wind farms do not have the same restriction in size of onshore wind turbines, such as availability of land or transportation requirements.[42]

Operating costs

Operational expenditures for wind farms are split between Maintenance (38%), Port Activities (31%), Operation (15%), License Fees (12%), and Miscellaneous Costs (4%).[47]

Operation and maintenance costs typically represent 53% of operational expenditures, and 25% - 30% of the total lifecycle costs for offshore wind farms. O&Ms are considered one of the major barriers for further development of this resource.

Maintenance of offshore wind farms is much more expensive than for onshore installations. For example, a single technician in a pickup truck can quickly, easily and safely access turbines on land in almost any weather conditions, exit his or her vehicle and simply walk over to and into the turbine tower to gain access to the entire unit within minutes of arriving onsite. Similar access to offshore turbines involves driving to a dock or pier, loading necessary tools and supplies into boat, a voyage to the wind turbine(s), securing the boat to the turbine structure, transferring tools and supplies to and from boat to turbine and turbine to boat and performing the rest of the steps in reverse order. In addition to standard safety gear such as a hardhat, gloves and safety glasses, an offshore turbine technician may be required to wear a life vest, waterproof or water-resistant clothing and perhaps even a survival suit if working, sea and atmospheric conditions make rapid rescue in case of a fall into the water unlikely or impossible. Typically at least two technicians skilled and trained in operating and handling large power boats at sea are required for tasks that one technician with a driver's license can perform on land in a fraction of the time at a fraction of the cost.

Cost of energy

Cost for installed offshore turbines fell 30% to $78/MWh in 2019, a more rapid drop than other types of renewable energy.[6] It has been suggested that innovation at scale could deliver 25% cost reduction in offshore wind by 2020.[48] Offshore wind power market plays an important role in achieving the renewable target in most of the countries around the world.

Auctions in 2016 for future projects have reached costs of €54.5 per megawatt hour (MWh) at the 700 MW Borssele 3&4[49] due to government tender and size,[50] and €49.90 per MWh (without transmission) at the 600 MW Kriegers Flak.[51]

In September 2017 contracts were awarded in the United Kingdom for a strike price of £57.50 per MWh making the price cheaper than nuclear and competitive with gas.[52]

In September 2018 contracts were awarded for Vineyard Wind, Massachusetts, USA at a cost of between $65-$74 per MWh.[53][54]

Offshore wind resources

Offshore wind resource characteristics span a range of spatial and temporal scales and field data on external conditions. For the North Sea, wind turbine energy is around 30 kWh/m2 of sea area, per year, delivered to grid. The energy per sea area is roughly independent of turbine size.[55]

Planning and permitting

A number of things are necessary in order to attain the necessary information for planning the commissioning of an offshore wind farm. The first information required is offshore wind characteristics. Additional necessary data for planning includes water depth, currents, seabed, migration, and wave action, all of which drive mechanical and structural loading on potential turbine configurations. Other factors include marine growth, salinity, icing, and the geotechnical characteristics of the sea or lake bed.

Existing hardware for measurements includes Light Detection and Ranging (LIDAR), Sonic Detection and Ranging (SODAR), radar, autonomous underwater vehicles (AUV), and remote satellite sensing, although these technologies should be assessed and refined, according to a report from a coalition of researchers from universities, industry, and government, supported by the Atkinson Center for a Sustainable Future.[56]

Because of the many factors involved, one of the biggest difficulties with offshore wind farms is the ability to predict loads. Analysis must account for the dynamic coupling between translational (surge, sway, and heave) and rotational (roll, pitch, and yaw) platform motions and turbine motions, as well as the dynamic characterization of mooring lines for floating systems. Foundations and substructures make up a large fraction of offshore wind systems, and must take into account every single one of these factors.[56] Load transfer in the grout between tower and foundation may stress the grout, and elastomeric bearings are used in several British sea turbines.[57]

Corrosion is also a serious problem and requires detailed design considerations. The prospect of remote monitoring of corrosion looks very promising using expertise utilised by the offshore oil/gas industry and other large industrial plants.

Some of the guidelines for designing offshore wind farms are IEC 61400-3,[58][59][60] but in the US several other standards are necessary.[61] In the EU, different national standards are to be straightlined into more cohesive guidelines to lower costs.[62] The standards requires that a loads analysis is based on site-specific external conditions such as wind, wave and currents.[63]

The planning and permitting phase can cost more than $10 million, take 5–7 years and have an uncertain outcome. The industry puts pressure on the governments to improve the processes.[64][65] In Denmark, many of these phases have been deliberately streamlined by authorities in order to minimize hurdles,[66] and this policy has been extended for coastal wind farms with a concept called ’one-stop-shop’.[67] The United States introduced a similar model called "Smart from the Start" in 2012.[68]

Turbine construction materials considerations

Since offshore wind turbines are located in oceans and large lakes, the materials used for the turbines have to be modified from the materials used for land based wind turbines and optimized for corrosion resistance to salt water and the new loading forces experienced by the tower being partially submerged in water. With one of the main reasons for interest in offshore wind power being the higher wind speeds, some of the loading differences will come from higher shearing forces between the top and bottom of the wind turbine due to differences in wind speeds. There should also be considerations for the buffeting loads that will be experienced by the waves around the base of the tower, which converges on the use of steel tubular towers for offshore wind applications.[69]

Since there’s constant exposure to salt and water for offshore wind turbines, the steel used for the monopile and turbine tower must be treated for corrosion resistance, especially at the base of the tower in the “splash zone” for waves breaking against the tower and in the monopile. Two techniques that can be used include cathode protection and the use of coatings to reduce corrosion pitting, which is a common source for hydrogen induced stress cracking.[70] For cathode protection, galvanized anodes are attached to the monopile and have enough of a potential difference with the steel to be preferentially corroded over the steel used in the monopile. Some coatings that have been applied to offshore wind turbines include hot dip zinc coatings and 2-3 epoxy coatings with a polyurethane topcoat.[70]

Installation

Specialized jackup rigs (Turbine Installation Vessels) are used to install foundation and turbine. As of 2019 the next generation of vessels are being built, capable of lifting 3-5,000 tons to 160 meters.[71]

A large number of monopile foundations have been used in recent years for economically constructing fixed-bottom offshore wind farms in shallow-water locations.[72][73] Each uses a single, generally large-diameter, foundation structural element to support all the loads (weight, wind, etc.) of a large above-surface structure.

The typical construction process for a wind turbine sub-sea monopile foundation in sand includes using a pile driver to drive a large hollow steel pile 25 m deep into the seabed, through a 0.5 m layer of larger stone and gravel to minimize erosion around the pile. These piles can be 4 m in diameter with approximately 50mm thick walls. A transition piece (complete with pre-installed features such as boat-landing arrangement, cathodic protection, cable ducts for sub-marine cables, turbine tower flange, etc.) is attached to the now deeply driven pile, the sand and water are removed from the centre of the pile and replaced with concrete. An additional layer of even larger stone, up to 0.5 m diameter, is applied to the surface of the seabed for longer-term erosion protection.[73]

For the ease of installing the towers and connecting them to the seabed, they are installed in two parts, the portion below the water surface and the portion above the water.[69] The two portions of the tower are joined by a transition piece which is filled with a grouted connection. The grouted connected helps transfer the loads experienced by the turbine tower to the more stable monopile foundation of the turbine. One technique for strengthening the grout used in the connections is to include weld beads known as shear keys along the length of the grout connection to prevent any sliding between the monopile and the tower.[74]

Grid connection

.jpg)

There are several different types of technologies that are being explored as viable options for integrating offshore wind power into the onshore grid. The most conventional method is through high-voltage alternating current (HVAC) transmission lines. HVAC transmission lines are currently the most commonly used form of grid connections for offshore wind turbines.[75] However, there are significant limitations that prevent HVAC from being practical, especially as the distance to offshore turbines increases. First, HVAC is limited by cable charging currents,[75] which are a result of capacitance in the cables. Undersea AC cables have a much higher capacitance than overhead AC cables, so losses due to capacitance become much more significant, and the voltage magnitude at the receiving end of the transmission line can be significantly different from the magnitude at the receiving end. In order to compensate for these losses, either more cables or reactive compensation must be added to the system. Both of these add costs to the system.[75] Additionally, because HVAC cables have both real and reactive power flowing through them, there can be additional losses.[76] Because of these losses, underground HVAC lines are limited in how far they can extend. The maximum appropriate distance for HVAC transmission for offshore wind power is considered to be around 80 km.[75]

Using high-voltage direct current (HVDC) cables has been a proposed alternative to using HVAC cables. HVDC transmission cables are not affected by the cable charging currents and experience less power loss because HVDC does not transmit reactive power.[77] With less losses, undersea HVDC lines can extend much farther than HVAC. This makes HVDC preferable for siting wind turbines very far offshore. However, HVDC requires power converters in order to connect to the AC grid. Both line commutated converters (LCCs) and voltage source converters (VSCs) have been considered for this. Although LCCs are a much more widespread technology and cheaper, VSCs have many more benefits, including independent active power and reactive power control.[77] New research has been put into developing hybrid HVDC technologies that have a LCC connected to a VSC through a DC cable.[77]

In order to transport the energy from offshore wind turbines to onshore energy plants, cabling has to be placed along the ocean floor. The cabling has to be able to transfer large amounts of current efficiently which requires optimization of the materials used for the cabling as well as determining cable paths for the use of a minimal amount of cable materials.[69] One way to reduce the cost of the cables used in these applications is to convert the copper conductors to aluminum conductors, however the suggested replacement brings up an issue of increased cable motion and potential damage since aluminum is less dense than copper.

Maintenance

Turbines are much less accessible when offshore (requiring the use of a service vessel or helicopter for routine access, and a jackup rig for heavy service such as gearbox replacement), and thus reliability is more important than for an onshore turbine.[1] Some wind farms located far from possible onshore bases have service teams living on site in offshore accommodation units.[78] To limit the effects of corrosion on the blades of a wind turbine, a protective tape of elastomeric materials is applied, though the droplet erosion protection coatings provide better protection from the elements.[79]

A maintenance organization performs maintenance and repairs of the components, spending almost all its resources on the turbines. The conventional way of inspecting the blades is for workers to rappel down the blade, taking a day per turbine. Some farms inspect the blades of three turbines per day by photographing them from the monopile through a 600mm lens, avoiding to go up.[80] Others use camera drones.[81]

Because of their remote nature, prognosis and health-monitoring systems on offshore wind turbines will become much more necessary. They would enable better planning just-in-time maintenance, thereby reducing the operations and maintenance costs. According to a report from a coalition of researchers from universities, industry, and government (supported by the Atkinson Center for a Sustainable Future),[56] making field data from these turbines available would be invaluable in validating complex analysis codes used for turbine design. Reducing this barrier would contribute to the education of engineers specializing in wind energy.

Decommissioning

As the first offshore wind farms reach their end of life, a demolition industry develops to recycle them at a cost of DKK 2-4 million per MW, to be guaranteed by the owner.[82] The first offshore wind farm to be decommissioned was Yttre Stengrund in Sweden in November 2015, followed by Vindeby in 2017 and Blyth in 2019.

Environmental impact

Offshore wind farms have very low global warming potential per unit of electricity generated, comparable to that of onshore wind farms. Offshore installations also have the advantage of limited impact of noise and on the landscape compared to land-based projects.

While the offshore wind industry has grown dramatically over the last several decades, there is still a great deal of uncertainty associated with how the construction and operation of these wind farms affect marine animals and the marine environment.[83] Common environmental concerns associated with offshore wind developments include:

- The risk of seabirds being struck by wind turbine blades or being displaced from critical habitats;

- The underwater noise associated with the installation process of driving monopile turbines into the seabed;

- The physical presence of offshore wind farms altering the behavior of marine mammals, fish, and seabirds with attraction or avoidance;

- The potential disruption of the nearfield and farfield marine environment from large offshore wind projects.[83]

The Tethys database provides access to scientific literature and general information on the potential environmental effects of offshore wind energy.[83]

Largest offshore wind farms

| Wind farm | Capacity (MW) |

Location | Site coordinates | Turbines & model | Commissioning date | Refs |

|---|---|---|---|---|---|---|

| Walney Extension | 659 | 54°5′17″N 3°44′17″W | 40 x MHI-Vestas 8.25 MW 47 x Siemens Gamesa 7 MW | 2018 | [84] | |

| London Array | 630 | 51°38′38″N 01°33′13″E | 175 × Siemens SWT-3.6-120 | 2012 | [85][86][87] | |

| Gemini Wind Farm | 600 | 54°2′10″N 05°57′47″W | 150 × Siemens SWT-4.0 | 2017 | [88][89][90][91] | |

| Beatrice | 588 | 58°07′48″N 03°04′12″W | 84 × 7MW Siemens Gamesa | 2019 | [92] | |

| Gode Wind (phases 1+2) | 582 | 54°04′N 7°02′E | 97 x Siemens SWT-6.0-154 | 2017 | [93][94] | |

| Gwynt y Môr | 576 | 53°27′00″N 03°35′00″W | 160 × Siemens SWT-3.6-107 | 2015 | [95] | |

| Race Bank | 573 | 53°16′N 0°50′E | 91 x Siemens SWT-6.0-154 | 2018 | [96][97] | |

| Greater Gabbard | 504[98] | 51°52′48″N 1°56′24″E | 140 × Siemens SWT-3.6-107 | 2012 | [99][100][101] | |

| Dudgeon | 402 | 53°14′56″N 1°23′24″E | 67 × Siemens 6 MW | 2017 | [102] | |

| Veja Mate | 402 | 54°19′1″N 5°52′15″E | 67 × Siemens SWT-6.0-154 | 2017 | [103][104] | |

| Anholt | 400 | 56°36′00″N 11°12′36″E | 111 × Siemens SWT-3.6-120 | 2013 | [105][106][107][108] | |

| BARD Offshore 1 | 400 | 54°22′0″N 5°59′0″E | 80 × BARD 5.0MW | 2013 | [109][110][111] | |

| Global Tech I | 400 | 54°30′00″N 6°21′30″E | 80 × Areva Multibrid M5000 5.0MW | 2015 | [112] | |

| West of Duddon Sands | 389 | 53°59′02″N 3°27′50″W | 108 × Siemens SWT-3.6-120 | 2014 | [113][114] | |

| Walney (phases 1&2) | 367 | 54°02′38″N 3°31′19″W | 102 × Siemens SWT-3.6-107 | 2011 (phase 1) 2012 (phase 2) | [115][116] | |

| Wikinger | 350 | 54°50′2″N 14°4′5″E | 70 x Adwen AD 5-135 | 2018 | [117] | |

| Nordsee One | 332 | 53°58′0″N 06°48′00″E | 54 × Senvion 6.2M126 | 2017 | [118] | |

| Thorntonbank (phases 1–3) | 325 | 51°33′00″N 2°56′00″E | 6 × Senvion 5MW 48 × Senvion 6.15MW | 2009 (phase 1) 2012 (phase 2) 2013 (phase 3) | [119][120][121][122] | |

| Sheringham Shoal | 315 | 53°7′0″N 1°8′0″E | 88 × Siemens SWT-3.6-107 | 2012 | [123][124][125][126] | |

| Borkum Riffgrund 1 | 312 | 53°58′0″N 06°33′00″E | 78 × Siemens SWT-4.0-120 | 2015 | [127] | |

| Amrumbank West | 302 | 54°30′0″N 07°48′00″E | 80 x Siemens SWT-3.6-120 | 2015 | [128] | |

| Thanet | 300 | 51°26′0″N 01°38′0″E | 100 × Vestas V90-3.0MW | 2010 | [129][130] |

Projects

Most of the current projects are in European and East Asian waters.

There are also several proposed developments in North America. Projects are under development in the United States in wind-rich areas of the East Coast, Great Lakes, and Pacific coast. In January 2012, a "Smart for the Start" regulatory approach was introduced, designed to expedite the siting process while incorporating strong environmental protections. Specifically, the Department of Interior approved “wind energy areas” off the coast where projects can move through the regulatory approval process more quickly.[131] The first offshore wind farm in the USA is the 30-megawatt, 5 turbine Block Island Wind Farm which was commissioned in December 2016.[132][133] Another offshore wind farm that is in the planning phase is off the coast of Virginia Beach. On August 3, 2018, Dominion Energy announced its two wind turbine pilot program that will be 27 miles offshore from Virginia Beach. The area is undergoing a survey that will last for 4–6 weeks.[134]

Canadian wind power in the province of Ontario is pursuing several proposed locations in the Great Lakes, including the suspended[135] Trillium Power Wind 1 approximately 20 km from shore and over 400 MW in capacity.[136] Other Canadian projects include one on the Pacific west coast.[137]

India is looking at the potential of offshore wind power plants, with a 100 MW demonstration plant being planned off the coast of Gujarat (2014).[138] In 2013, a group of organizations, led by Global Wind Energy Council (GWEC) started project FOWIND (Facilitating Offshore Wind in India) to identify potential zones for development of off-shore wind power in India and to stimulate R & D activities in this area. In 2014 FOWIND commissioned Center for Study of Science, Technology and Policy (CSTEP) to undertake pre-feasibility studies in eight zones in Tamil Nadu which have been identified as having potential.[139]

Offshore wind power by country

Most of offshore wind farms are currently in northern Europe. The United Kingdom and Germany alone accounted for roughly two thirds of the total offshore wind power capacity installed worldwide in 2016. Other countries, such as China, are rapidly expanding their offshore wind power capacity.

| Rank | Country | 2016 | 2017 | 2018 |

|---|---|---|---|---|

| 1 | United Kingdom | 5,156 | 6,651 | 7,963 |

| 2 | Germany | 4,108 | 5,411 | 6,380 |

| 3 | China | 1,627 | 2,788 | 4,588 |

| 4 | Denmark | 1,271 | 1,268 | 1,329 |

| 5 | Belgium | 712 | 877 | 1,186 |

| 6 | Netherlands | 1,118 | 1,118 | 1,118 |

| 7 | Sweden | 202 | 202 | 192 |

| 8 | Vietnam | 99 | 99 | 99 |

| 9 | South Korea | 35 | 38 | 73 |

| 10 | Finland | 32 | 92 | 87 |

| 11 | Japan | 60 | 65 | 65 |

| 12 | United States | 30 | 30 | 30 |

| 13 | Ireland | 25 | 25 | 25 |

| 14 | Taiwan | 0 | 8 | 8 |

| 15 | Spain | 5 | 5 | 5 |

| 16 | Norway | 2 | 2 | 2 |

| 17 | France | 0 | 2 | 2 |

| World total | 14,482 | 18,658 | 23,140 |

See also

| Wikimedia Commons has media related to Offshore wind power. |

- List of offshore wind farms

- Lists of offshore wind farms by water area

References

- Madsen & Krogsgaard. Offshore Wind Power 2010 Archived June 30, 2011, at the Wayback Machine BTM Consult, 22 November 2010. Retrieved: 22 November 2010.

- "Global Wind Report 2018" (PDF). gwec.net. Global Wind Energy Council (GWEC). Retrieved 22 May 2019.

- Vaughan, Adam (2018-09-06). "World's largest offshore windfarm opens off Cumbrian coast". The Guardian. Retrieved 6 September 2018.

- "Orsted clears Taiwan hurdle". reNEWS - Renewable Energy News. 6 December 2017. Retrieved 7 December 2017.

- Levelized Cost of New Generation Resources in the Annual Energy Outlook 2011. Released December 16, 2010. Report of the US Energy Information Administration (EIA) of the U.S. Department of Energy (DOE).

- Lee, Andrew (22 October 2019). "Offshore wind power price plunges by a third in a year". Recharge | Renewable energy news and articles.

- "After a decade of dithering, the US east coast went all in on offshore wind power this week". Retrieved 29 September 2018.

- "GWEC Global Wind Statistics 2014" (PDF). Global Wind Energy Council. 10 February 2015.

- "Global Wind Statistics 2015" (PDF). Global Wind Energy Council (GWEC). 10 February 2016. Retrieved 14 April 2017.

- "OFFSHORE WIND | GWEC". www.gwec.net. Retrieved 5 August 2017.

- "Wind in our Sails, A report by the European Wind Energy Association - 2011" (PDF). European Wind Energy Association. 2011. p. 11. Retrieved 27 February 2015.

- Environmental and Energy Study Institute (October 2010). "Offshore Wind Energy" (PDF).

- Lindvig, Kaj. The installation and servicing of offshore wind farms p6 A2SEA, 16 September 2010. Accessed: 9 October 2011.

- Nymark, Jens. Seaturbines competitive in 15 years Archived November 16, 2011, at the Wayback Machine Børsen, 15 November 2011. Accessed: 10 December 2011.

- Justin Wilkes et al. The European offshore wind industry key 2011 trends and statistics European Wind Energy Association, January 2012. Accessed: 26 March 2012.

- 17 EU countries planning massive offshore wind power ROV world, 30 November 2011. Accessed: 10 December 2011.

- Tildy Bayar (30 September 2011). "Wind Energy Markets: Experts See Solid Offshore Growth". Renewable Energy World.

- Bakewell, Sally (29 October 2012). "Largest Offshore Wind Farm Generates First Power in U.K." Bloomberg. Retrieved 19 December 2012.

- Platt, Jim (2013). "The offshore wind energy nano-industry". Nanotechnology Perceptions. 9 (2): 91–95. doi:10.4024/N04PL13A.ntp.09.02.

- "The offshore wind energy nano-industry". Retrieved 20 May 2016.

- "Wind in power 2013 European statistics" The European Wind Energy Association, 2014

- The European offshore wind industry - key trends and statistics 2013 ,The European Wind Energy Association, 2014

- "Wind in Power: 2014 European statistics". European Wind Energy Association (EWEA). Retrieved 2014-03-16.

- Ho, Andrew (2015). The European offshore wind industry - key trends and statistics 2015 (PDF). European Wind Energy Association. p. 10. Retrieved 29 April 2019.

- "Detailed appraisal of the offshore wind industry in China". The Carbon Trust. May 2014. Retrieved 22 July 2014.

- "China tops offshore turbine chart". reNEWS - Renewable Energy News. 22 February 2017. Retrieved 26 February 2017.

- Ryan, Joe (2 May 2016). "A U.S. State Has Key to $10 Billion Offshore Wind Boom". Bloomberg.com. Retrieved 2 June 2016.

- Jessica Shankleman (28 April 2016). "World's Biggest Windmills Now Make Jumboi Jets Look Tiny". Bloomberg.com. Retrieved 2 June 2016.

- "Global Wind Industry Hits Record 62 GW Installed In 2015". CleanTechnica. 2016-02-03.

- Stiesdal, Henrik (21 December 2016). "Midt i en disruptionstid". Ingeniøren. Retrieved 21 December 2016.

Real prices have moved to half of what the experts predicted

- "Price diagram: Real and predicted prices for offshore wind power".

- Tillessen, Teena (2010). "High demand for wind farm installation vessels". Hansa International Maritime Journal. Vol. 147 no. 8. pp. 170–171.

- The Ocean Economy in 2030, pp.205-212. OECD iLibrary, 27 April 2016. ISBN 9264251723 . Web read

- "Challenges in design of foundations for offshore wind turbines". The E&T Energy and Power Hub. The E&T Energy and Power Hub. 9 August 2017. Archived from the original on 7 December 2017. Retrieved 7 December 2017.

- "Offshore wind foundation shift hinges on serial build gains | New Energy Update". analysis.newenergyupdate.com. 15 May 2019. Archived from the original on 2019-10-05.

- "Installation Vessels: Reaching the Limit and Beyond". 2017-03-27. Retrieved 19 April 2017.

- Perez-Collazo, C (2 January 2015). "A review of combined wave and offshore wind energy". Elsevier.

- "Classification and Certification of Floating Offshore Wind Turbines" Archived December 3, 2013, at the Wayback Machine Bureau Veritas, November 2010. Retrieved: 16 August 2012.

- Elaine Kurtenbach. "Japan starts up offshore wind farm near Fukushima" The Sydney Morning Herald, 12 November 2013. Accessed: 11 November 2013.

- "Japan: Experimental Offshore Floating Wind Farm Project" OffshoreWind, 11 October 2013. Accessed: 12 October 2013.

- Madslien, Jorn (5 June 2009). "Floating wind turbine launched". BBC News. Retrieved 14 September 2009.

- Sun, Xiaojing; Huang, Diangui; Wu, Guoqing (May 2012). "The current state of offshore wind energy technology development". Energy. 41 (1): 298–312. doi:10.1016/j.energy.2012.02.054.

- "Studie: Stromgestehungskosten erneuerbare Energien - März 2018". Fraunhofer ISE. 2018. Retrieved 2 April 2018.

- "Wind Power". New York Times. January 27, 2002.

- Prinds, Karsten (20 April 2011). "Where offshore wind was invented". LORC. Archived from the original on 29 April 2016. Retrieved 27 February 2017.

- Poulsen, Thomas; Lema, Rasmus (1 June 2017). "Is the supply chain ready for the green transformation? The case of offshore wind logistics". Renewable and Sustainable Energy Reviews. 73: 758–771. doi:10.1016/j.rser.2017.01.181.

- Röckmann C., Lagerveld S., Stavenuiter J. (2017) Operation and Maintenance Costs of Offshore Wind Farms and Potential Multi-use Platforms in the Dutch North Sea. In: Buck B., Langan R. (eds) Aquaculture Perspective of Multi-Use Sites in the Open Ocean. Springer, Cham

- "Offshore Wind Accelerator". The Carbon Trust. Retrieved 22 July 2014.

- "Oil & Gas Giant to Build Dutch Borssele III & IV Offshore Wind Farms". Offshore Wind. 12 December 2016. Retrieved 14 December 2016.

- "Tender design, output gains key to DONG's record-low Borssele 1&2 offshore bid price". 17 August 2016. Archived from the original on 17 September 2016. Retrieved 17 September 2016.

- Steel, William (9 November 2016). "Vattenfall wins Kriegers Flak with record €49.90/MWh". Recharge. Archived from the original on 10 November 2016. Retrieved 10 November 2016.

- "Offshore wind cheaper than nuclear as auction smashes expectations". 2017-09-11. Retrieved 29 September 2018.

- "A Stunningly Low Price for Offshore Wind: Massachusetts Moves Forward". 2018-09-26. Retrieved 29 September 2018.

- "First Large US Offshore Wind Project Sets Record-Low Price Starting at $74 per MWh". August 2018. Retrieved 29 September 2018.

- Stiesdal, Henrik. "Pi and turbines - a useful context" Original, in Danish Ingeniøren, 13 March 2015. Accessed: 13 March 2015.

- Zehnder, Alan; Warhaft, Zellman, eds. (2011). "University Collaboration on Wind Energy" (PDF). Cornell University. Retrieved 13 January 2016.

- Tramontana, Tea (31 October 2012). "Overcoming problems with crumbling grout". LORC. Archived from the original on 12 May 2016. Retrieved 27 February 2017.

- "Wind turbines Part 3: Design requirements for offshore wind turbines" Austrian Standards Institute. Retrieved: 16 August 2012.

- International Standard IEC 61400-3 International Electrotechnical Commission, August 2005. Accessed: 12 March 2011.

- Quarton, D.C. "An international design standard for offshore wind turbines: IEC 61400-3" Archived July 21, 2011, at the Wayback Machine Garrad Hassan, 2005. Accessed: 12 March 2011.

- Musial, W. D.; Sheppard, R. E.; Dolan, D.; Naughton, B. "Development of Offshore Wind Recommended Practice for U.S. Waters" National Renewable Energy Laboratory, April 2013. Accessed: 20 November 2013. OSTI ID: 1078076

- "Archived copy". Archived from the original on 2016-08-09. Retrieved 2016-06-06.CS1 maint: archived copy as title (link)

- Jonkman, J.M. "Dynamics Modeling and Loads Analysis of an Offshore Floating Wind Turbine" Technical Report NREL/TP-500-41958 page 75, NREL November 2007. Retrieved: 25 June 2012.

- Jamie D. (2009-06-11). "N.J. must make wind farm permitting process as quick and easy as possible | Commentary | NewJerseyNewsroom.com - Your State. Your News". NewJerseyNewsroom.com. Retrieved 2013-07-06.

- Subtask 1: Critical Deployment Issues at the Wayback Machine (archived August 28, 2009)

- Streamline Renewable Energy Policy and make Australia a World Leader Energy Matters, 11 August 2010. Retrieved: 6 November 2010.

- "Nearshore wind turbines in Denmark" (in Danish). Danish Energy Agency, June 2012. Retrieved: 26 June 2012.

- "Smart from the Start" Bureau of Ocean Energy Management. Accessed: 20 November 2013.

- Chong, Ng (2016-03-03). Offshore wind farms : technologies, design and operation. Ng, Chong,, Ran, Li. Duxford, UK: Elsevier, WP Woodhead Publishing. ISBN 978-0-08-100780-8. OCLC 944186047.CS1 maint: date and year (link)

- Black, Anders Rosborg; Mathiesen, Troels; Hilbert, Lisbeth Rischel (2015-05-12). "Corrosion Protection of Offshore Wind Foundations". NACE International. Cite journal requires

|journal=(help) - Lars Paulsson, Jeremy Hodges, and Chris Martin (13 May 2019). "Offshore Wind Will Need Bigger Boats. Much Bigger Boats". Bloomberg.CS1 maint: multiple names: authors list (link)

- Offshore Wind Turbine Foundations Archived 2010-02-28 at the Wayback Machine, 2009-09-09, accessed 2010-04-12.

- Constructing a turbine foundation Archived 21 May 2011 at the Wayback Machine Horns Rev project, Elsam monopile foundation construction process, accessed 2010-04-12]

- Tziavos, Nikolaos I.; Hemida, Hassan; Metje, Nicole; Baniotopoulos, Charalampos (2016-06-08). "Grouted connections on offshore wind turbines: a review" (PDF). Proceedings of the Institution of Civil Engineers - Engineering and Computational Mechanics. 169 (4): 183–195. doi:10.1680/jencm.16.00004. ISSN 1755-0777.

- Daniel, John; Liu, Shu; Ibanez, Eduardo; Pennock, Ken; Reed, Gregory; Hanes, Spencer. "National Offshore Wind Energy Grid Interconnection Study Executive Summary" (PDF). Retrieved 1 May 2019.

- Anaya-Lara, Olimpo; Campos-Gaona, David; Moreno-Goytia, Edgar; Adam, Grain (10 April 2014). Grid Integration of Offshore Wind Farms – Case Studies. Wiley. doi:10.1002/9781118701638.ch5. ISBN 9781118701638.

- Torres-Olguin, Raymundo; Molinas, Marta; Undeland, Tore (October 2012). "Offshore Wind Farm Grid Integration by VSC Technology With LCC-Based HVDC Transmission". IEEE Transactions on Sustainable Energy. 3 (4): 899. Bibcode:2012ITSE....3..899T. doi:10.1109/TSTE.2012.2200511.

- Accommodation Platform Archived July 19, 2011, at the Wayback Machine DONG Energy, February 2010. Retrieved: 22 November 2010.

- Valaker, E.A.; Armada, S.; Wilson, S. (2015). "Droplet Erosion Protection Coatings for Offshore Wind Turbine Blades". Energy Procedia. 80: 263–275. doi:10.1016/j.egypro.2015.11.430.

- Bjørn Godske (2016-06-02). "Dong bruger supertele til vingeinspektion". Ingeniøren. Retrieved 5 June 2016.

- "3 Ways to Inspect a Blade". E.ON energized. Retrieved 5 June 2016.

- "Aldrende havmølleparker åbner marked for klog nedrivning". Ingeniøren. 2016-02-20. Retrieved 20 May 2016.

- "Environmental Effects of Wind and Marine renewable Energy". Tethys. 2017.

- "About the project: The world´s largest offshore wind farm". Orsted. 2018.

- "London Array's own website announcement of commencement of offshore works" (PDF). londonarray.com. Archived from the original (PDF) on 14 October 2019. Retrieved 4 April 2018.

- Wittrup, Sanne. First foundation Ing.dk, 8 March 2011. Accessed: 8 March 2011.

- "London Array - The Project". London Array. 2015. Archived from the original on 21 February 2014. Retrieved 10 June 2015.

- "Facts - figures". Gemini wind park. 2017. Archived from the original on 10 April 2018. Retrieved 4 April 2018.

- "The 600-MW Gemini offshore wind farm is successfully up & running". Archived from the original on 2017-05-01. Retrieved 2017-06-01.

- "Gemini offshore wind project fully completed".

- "Gemini Offshore Wind Farm". 4c Offshore. Retrieved 4 September 2015.

- "Scotland's largest offshore wind farm officially opened". BBC News. 2009-07-29. Retrieved 2019-07-29.

- "Gode Wind foundation installed successfully". 4coffshore.com. Retrieved 4 September 2015.

- "DONG Energy Inaugurates 582 Megawatt Gode Wind I & 2 Offshore Wind Farms". CleanTechnica. Retrieved 3 July 2017.

- DENHOLM-HALL, RUPERT (2015-06-18). "World's second largest offshore wind farm opens off coast of Wales". Wales Online. Archived from the original on 19 June 2015. Retrieved 18 June 2015.

- "Full power at Race Bank Offshore Wind Farm". orsted.com. Retrieved 2018-02-02.

- "Innovation Installs First Foundation at Race Bank". offshorewind.biz/. 2016-06-30. Retrieved 2 July 2016.

- 504 MW extension is planned

- "UK: Greater Gabbard Offshore Wind Farm Generates Power". 2012-09-07. Retrieved 2012-09-07.

- "Offshore Wind Farms 2008" (PDF). EWEA. 2009-02-02. Retrieved 2009-02-04.

- "SSE plc - The UK's broadest-based energy company". scottish-southern.co.uk. Retrieved 10 June 2015.

- "Dudgeon hits CfD milestone". renews.biz. 4 October 2017. Retrieved 4 April 2018.

- "World's Largest OW Jack-Up Vessel Installs World's Heaviest Monopile at Veja Mate OWF". 2016-04-06. Retrieved 6 June 2016.

- "Construction complete for 402-MW Veja Mate offshore wind park". Renewables Now. Retrieved 31 May 2017.

- "VIPs cut ribbon at 400MW Anholt" Recharge News, 4 September 2013. Accessed: 4 September 2013.

- Jan Bjerre Lauridsen & Søren Andersen. "Queen says Good Wind to giant turbines" Berlingske, 4 September 2013. Accessed: 4 September 2013.

- "All turbines at Anholt Offshore wind farm now operational" (Press release). DONG Energy. 20 June 2013. Archived from the original on 6 October 2013. Retrieved 27 August 2013.

- Anholf Offshore wind farm in 4C Offshore Retrieved 2013-08-27

- "BARD Offshore Wind Farm". 4c Offshore. Retrieved 10 June 2015.

- Rösler eröffnet Offshore-Windpark Bard 1 Archived 2013-08-28 at the Wayback Machine Retrieved 2013-08-26

- German Federal Minister Inaugurates BARD Offshore 1 Retrieved 2013-08-26

- "Global Tech I officially inaugurated". sunwindenergy.com/. 2015-09-04. Retrieved 4 September 2015.

- "West of Duddon Sands reaches foundation installation halfway point". Orsted. 2013. Retrieved 2013-08-27.

- "West of Duddon Sands". Retrieved 2013-08-27.

- Datasheet for site: Walney 1 Offshore wind farm Archived 2011-03-26 at the Wayback Machine. LORC Knowledge, 2011

- "UK: Walney Offshore Wind Farm Fully Operational". 2012-06-14. Retrieved 2012-06-15.

- "Construction is starting on the offshore wind farm Wikinger". 2016-03-22. Retrieved 23 March 2016.

- http://www.offshorewindindustry.com/news/first-foundation-nordsee-one-successfully First foundation for Nordsee One successfully installed

- C-Power: General Informations Archived 2012-04-23 at the Wayback Machine

- "RWE Innogy - Press release 09 July 2013 Export cables in at Gwynt y Môr Offshore Wind Farm". rwe.com. Retrieved 10 June 2015.

- "Phase 2 completed". RePower - All the energy you need. Retrieved 4 April 2018.

- "Belgium: Thornton Bank Offshore Wind Farm Officially Inaugurated". Offshore Wind. 2013-09-18. Retrieved 10 June 2015.

- "SWT-3.6-107 Wind Turbine". Siemens. Archived from the original on 2008-07-25. Retrieved 2009-07-19.

- "Sheringham Shoal Offshore Wind Farm" (PDF). StatoilHydro. Retrieved 2009-07-19.

- Trickyweb (2015). "Sheringham Shoal Operated by Statkraft". SHERINGHAM SHOAL, Offshore Wind Farm. Retrieved 10 June 2015.

- "Norway's Crown Prince Opens Sheringham Shoal Offshore Wind Farm (UK)". Offshore Wind. 2012-09-27. Retrieved 10 June 2015.

- "Borkum Riffgrund I". 4coffshore.com. Retrieved 4 September 2015.

- "Amrumbank West - 4C Offshore". www.4coffshore.com. Retrieved 2018-04-20.

- "Thanet". The Engineer Online. 2008-07-25. Retrieved 2008-11-26.

- "Thanet offshore wind farm starts electricity production". BBC News. 2010-09-23. Retrieved 2010-09-30.

- Kit Kennedy (2 February 2012). "Offshore Wind One Step Closer to Reality in the Mid-Atlantic". Renewable Energy World.

- "America Is Finally Getting Its First Offshore Wind Farm. Conservatives Are Trying to Make Sure It's the Last". New Republic. 14 May 2015. Retrieved 15 May 2015.

- "Block Island Wind Farm - Deepwater Wind". Deepwater Wind. Retrieved 20 May 2016.

- "Offshore wind energy heading to waters off Virginia Beach". WVEC. Retrieved 2018-08-14.

- Offshore wind development hits a snag in Ontario Archived 2012-01-09 at the Wayback Machine Alberta Oil Magazine, April 2011. Accessed: 29 September 2011.

- Hamilton, Tyler (January 15, 2008). "Ontario to approve Great Lakes wind power". The Star. Toronto. Retrieved 2008-05-02.

- "Naikun Wind Development, Inc". Retrieved 2008-05-21.

- "MOU Signed for First Ever Offshore Wind Power Project in India". www.pib.nic.in. Press Information Bureau, Government of India. October 1, 2014. Retrieved 30 April 2015.

- R. Srikanth; Sangeetha Kandavel (January 29, 2015). "Tapping the offshore wind". The Hindu. Retrieved 30 April 2015.