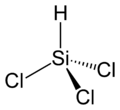

Trichlorosilane

Trichlorosilane is an inorganic compound with the formula HSiCl3. It is a colourless, volatile liquid. Purified trichlorosilane is the principal precursor to ultrapure silicon in the semiconductor industry. In water, it rapidly decomposes to produce a silicone polymer while giving off hydrochloric acid. Because of its reactivity and wide availability, it is frequently used in the synthesis of silicon-containing organic compounds.[1]

| |||

| |||

| Names | |||

|---|---|---|---|

| IUPAC name

trichlorosilane | |||

| Other names

silyl trichloride, silicochloroform | |||

| Identifiers | |||

3D model (JSmol) |

|||

| ChemSpider | |||

| ECHA InfoCard | 100.030.026 | ||

| EC Number |

| ||

PubChem CID |

|||

| RTECS number |

| ||

| UNII | |||

| UN number | 1295 | ||

CompTox Dashboard (EPA) |

|||

| |||

| |||

| Properties | |||

| HCl3Si | |||

| Molar mass | 135.45 g/mol | ||

| Appearance | colourless liquid | ||

| Density | 1.342 g/cm3 | ||

| Melting point | −126.6 °C (−195.9 °F; 146.6 K) | ||

| Boiling point | 31.8 °C (89.2 °F; 304.9 K) | ||

| hydrolysis | |||

| Hazards | |||

| Safety data sheet | ICSC 0591 | ||

EU classification (DSD) (outdated) |

Highly flammable (F+) Harmful (Xn) Corrosive (C) | ||

| R-phrases (outdated) | R12, R14, R17, R20/22, R29, R35 | ||

| S-phrases (outdated) | (S2), S7/9, S16, S26, S36/37/39, S43, S45 | ||

| NFPA 704 (fire diamond) | |||

| Flash point | −27 °C (−17 °F; 246 K) | ||

| 185 °C (365 °F; 458 K) | |||

| Explosive limits | 1.2–90.5% | ||

| Related compounds | |||

Related chlorosilanes |

Chlorosilane Dichlorosilane Dichloromethylsilane Chlorodimethylsilane Silicon tetrachloride | ||

Related compounds |

Trifluorosilane Tribromosilane Chloroform | ||

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |||

| Infobox references | |||

Production

Trichlorosilane is produced by treating powdered metallurgical grade silicon with blowing hydrogen chloride at 300 °C. Hydrogen is also produced, as described in the chemical equation:

- Si + 3 HCl → HCl3Si + H2

Yields of 80-90% can be achieved. The major byproducts are silicon tetrachloride (chemical formula SiCl4), hexachlorodisilane (Si2Cl6), and dichlorosilane (H2SiCl2), from which trichlorosilane can be separated by distillation.

- Tank car of trichlorosilane (the blue diamond means "Dangerous when wet").

It is also produced from silicon tetrachloride:[2]

- Si + 3 SiCl4 + 2 H2 → 4 HSiCl3

Applications

Trichlorosilane is the basic ingredient used in the production of purified polysilicon.

- HSiCl3 → Si + HCl + Cl2

Ingredient in hydrosilylation

Via hydrosilylation, trichlorosilane is a precursor to other useful organosilicon compounds:

- RCH=CH2 + HSiCl3 → RCH2CH2SiCl3

Some useful products of this or similar reactions include octadecyltrichlorosilane (OTS), perfluoroctyltrichlorosilane (PFOTCS), and perfluorodecyltrichlorosilane (FDTS). These reagents used in surface science and nanotechnology to form Self-assembled monolayers. Such layers containing fluorine decrease surface energy and reduce sticking. This effect is usually exploited as coating for MEMS and microfabricated stamps for a nanoimprint lithography (NIL) and in injection molding tools.[3]

Organic synthesis

Trichlorosilane is a reagent in the conversion of benzoic acids to toluene derivatives. In the first step of a two-pot reaction, the carboxylic acid is first converted to the trichlosilylbenzyl compound. In the second step, the benzylic silyl derivative is converted to the toluene derivative with base.[4]

References

- Lianhong Xu, Ravi Kurukulasuriya, "Trichlorosilane" Encyclopedia of Reagents for Organic Synthesis, 2006. doi:10.1002/047084289X.rt213.pub2

- Simmler, W. "Silicon Compounds, Inorganic". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a24_001.

- Cech J, Taboryski R (2012). "Stability of FDTS monolayer coating on aluminum injection molding tools". Applied Surface Science. 259: 538–541. Bibcode:2012ApSS..259..538C. doi:10.1016/j.apsusc.2012.07.078.

- George S. Li, David F. Ehler, R. A. Benkeser "Methyl Groups By Reduction Of Aromatic Carboxylic Acids With Trichlorosilane - Tri-n-propylamine: 2-methylbiphenyl" Org. Synth. 1977, volume 56, pp. 83. doi:10.15227/orgsyn.056.0083