Propfan

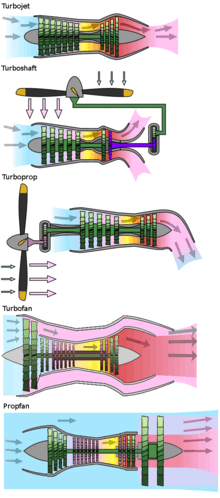

A propfan, also called an open rotor engine, or unducted fan (as opposed to a ducted fan), is a type of aircraft engine related in concept to both the turboprop and turbofan, but distinct from both. The design is intended to offer the speed and performance of a turbofan, with the fuel economy of a turboprop. A propfan is typically designed with a large number of short, highly twisted blades, similar to a turbofan's bypass compressor (the fan itself). For this reason, the propfan has been variously described as an "unducted fan" or an "ultra-high-bypass (UHB) turbofan."

.jpg)

| Part of a series on |

| Aircraft propulsion |

|---|

|

Shaft engines: driving propellers, rotors, ducted fans or propfans |

| Reaction engines |

Definition

In the 1970s, Hamilton Standard described its propfan as "a small diameter, highly loaded multiple bladed variable pitch propulsor having swept blades with thin advanced airfoil sections, integrated with a nacelle contoured to retard the airflow through the blades thereby reducing compressibility losses and designed to operate with a turbine engine and using a single stage reduction gear resulting in high performance."[1] In 1982, the weekly aviation magazine Flight International defined the propfan as a propeller with 8–10 highly swept blades that cruised at a speed of 390–480 knots (450–550 miles per hour; 720–890 kilometres per hour),[2] although its definition evolved a few years later with the emergence of contra-rotating propfans.[3]

In 1986, British engine maker Rolls-Royce used the term open rotor as a synonym for the original meaning of a propfan. This action was to delineate the propfan engine type from a number of ducted engine proposals at the time that had propfan in their names.[4] By the 2000s, open rotor (OR) became a preferred term for propfan technology in research and news reports, with contra-rotating open rotor (CROR) also occasionally being used to distinguish between single-rotation propfans. As of 2015, the European Aviation Safety Agency (EASA) defined an open rotor concretely (but broadly) as "a turbine engine fan stage that is not enclosed within a casing;" in contrast, it had only a working definition of an open rotor engine (the more commonly used term for propfan in the 21st century), calling it "a turbine engine featuring contra-rotating fan stages not enclosed within a casing." The engine uses a gas turbine to drive an unshrouded (open) contra-rotating propeller like a turboprop, but the design of the propeller itself is more tightly coupled to the turbine design, and the two are certified as a single unit.[5]

El-Sayed differentiates between turboprops and propfans according to 11 different criteria, including number of blades, blade shape, tip speed, bypass ratio, Mach number, and cruise altitude.[6]

Development

About a decade after German aerospace engineers began exploring the idea of using swept wings to reduce drag on transonic speed aircraft, Hamilton Standard in the 1940s attempted to apply a similar concept to engine propellers. It created highly swept propeller blades with supersonic tip speeds, so that engines with exposed propellers could power aircraft to speeds and cruising altitudes only attained by new turbojet and turbofan engines. Early tests of these blades revealed then-unresolvable blade flutter and blade stress problems, and high noise levels were considered another obstacle. The popularity of turbojets and turbofans curtailed research in propellers, but by the 1960s, interest increased when studies showed that an exposed propeller driven by a gas turbine could power an airliner flying at a speed of Mach 0.7–0.8 and at an altitude of 35,000 feet (11,000 metres). The term propfan was created during this time.[7]

One of the earliest engines that resembled the propfan concept was the 4,710 pounds-force (21.0 kilonewtons) Metrovick F.5, which featured twin contra-rotating fans—14 blades in the fore (front) fan and 12 blades in the aft (back) fan—at the rear of the engine and was first run in 1946. The blades, however, were mostly unswept.[8] There were other contra-rotating propeller engines that featured on common aircraft, such as the four powerful Kuznetsov NK-12 engines (each powering its own set of coaxial contra-rotating propellers) on the Soviet Union's Tupolev Tu-95 Bear high-speed military bomber and Antonov An-22 military transport aircraft, and the Armstrong Siddeley Double Mamba (ASMD) engines (both connected to a lone set of coaxial contra-rotating propellers) on the British Fairey Gannet anti-submarine aircraft. Both setups had four blades in the front propeller and the back propeller, but they were also largely unswept.

1970s–1980s

When the 1973 oil crisis caused the petroleum price spikes in the early 1970s, interest in propfans soared, and NASA-funded research began to accelerate.[9] The propfan concept was outlined by Carl Rohrbach and Bruce Metzger of the Hamilton Standard division of United Technologies in 1975[10] and was patented by Rohrbach and Robert Cornell of Hamilton Standard in 1979.[1] Later work by General Electric on similar propulsors was done under the name unducted fan, which was a modified turbofan engine, with the fan placed outside the engine nacelle on the same axis as the compressor blades.

During this era, the propeller problems encountered a few decades ago became fixable. Advances were made in structural materials, such as titanium metal and graphite and glass fiber composites infused with resin. These materials replaced aluminum and steel metals in blade construction, which allowed the blades to be made thinner and stronger.[11] Computer-aided design was also useful in refining the blade characteristics. Since the blades bend and deflect with higher power loading and centrifugal force, the initial designs needed to be based on the in-motion shape. With the help of computers, the blade designers would then work backward to find the optimal unloaded shape for manufacturing purposes.[12]

Flight test programs

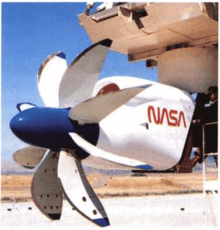

Hamilton Standard, the only remaining large American manufacturer of aircraft propellers, developed the propfan concept in the early 1970s.[13] Numerous design variations of the propfan were tested by Hamilton Standard, in conjunction with NASA in this decade.[14][15] This testing led to the Propfan Test Assessment (PTA) program, where Lockheed-Georgia proposed modifying a Gulfstream II to act as in-flight testbed for the propfan concept, while McDonnell Douglas proposed modifying a DC-9 for the same purpose.[16] NASA chose the Lockheed proposal, where the aircraft had a nacelle added to the left wing, containing a 6,000 horsepower (4,500 kilowatts) Allison 570 turboprop engine (derived from the XT701 turboshaft developed for the Boeing Vertol XCH-62 heavy lift helicopter). The engine used an eight-bladed, 9-foot diameter (2.7-metre; 110-inch; 270-centimetre), single-rotation Hamilton Standard SR-7 propfan as its propulsor. The test engine, which was named the Allison 501-M78,[17] had a thrust rating of about 8,000 lbf (36 kN),[18] and it was first operated in flight on March 28, 1987.[19] The extensive test program, which cost about $56 million,[20] racked up 73 flights and over 133 hours of flight time before finishing on March 25, 1988, although most of the flight testing was done in 1987.[21] In 1989, however, the testbed aircraft returned to the air from April 3 through April 14 to measure ground noise levels during en-route flying.[22][23] The engine was removed after that, and the aircraft was converted to a space shuttle training aircraft later that year.[24]

_McDonnell_Douglas_demonstrator%2C_Farnborough_UK_-_England%2C_September_1988_(5589809360).jpg)

The GE36 Unducted Fan (UDF), from the American engine maker General Electric (GE) with 35-percent participation from French partner Snecma (now Safran), was a variation on the original propfan concept and resembled a pusher configuration piston engine. GE's UDF had a novel direct-drive arrangement, where the reduction gearbox was replaced by a low-speed seven-stage free turbine. One set of turbine rotors drove the forward set of propellers, while the rear set was driven by the other set of rotors which rotated in the opposite direction. The turbine had 14 blade rows with seven stages. Each stage was a pair of contra-rotating rows.[25] Airframers, who had been wary of issue-prone gearboxes since the 1950s, liked GE's gearless version of the propfan:[12] Boeing intended to offer GE's pusher UDF engine on the 7J7 platform (which would have had a cruise speed of Mach 0.83),[26] and McDonnell Douglas was going to do likewise on their MD-94X airliner. The GE36 was first flight tested mounted on the #3 engine station of a Boeing 727-100 on August 20, 1986.[27] The GE36 UDF for the 7J7 was planned to have a thrust of 25,000 pounds-force (110 kN), but GE claimed that in general its UDF concept could cover a thrust range of 9,000 to 75,000 lbf (40 to 334 kN),[28] so a UDF engine could possibly match or surpass the thrust of the CF6, GE's family of widebody engines at that time.

McDonnell Douglas developed a proof-of-concept aircraft by modifying its company-owned MD-80, which is suited for propfans due to its aft fuselage-mounted engines (like its DC-9 ancestor), in preparation for the possible propfan-powered MD-91 and MD-92 derivatives and a possible MD-94X clean-sheet aircraft. They removed the JT8D turbofan engine from the left side of the fuselage and replaced it with the GE36. Test flights began in May 1987,[29] initially out of Mojave, California, which proved the airworthiness, aerodynamic characteristics, and noise signature of the design. Following the initial tests, a first-class cabin was installed inside the aft fuselage and airline executives were offered the opportunity to experience the UDF-powered aircraft first-hand. The test and marketing flights of the GE-outfitted demonstrator aircraft concluded in 1988, exhibiting a 30% reduction in fuel consumption over turbo-fan powered MD-80, full Stage 3 noise compliance, and low levels of interior noise/vibration. The GE36 would have the same 25,000 lbf (110 kN) thrust on the MD-92X, but the same engine would be derated to 22,000 lbf (98 kN) thrust for the smaller MD-91X. The MD-80 was also successfully flight tested in April 1989 with the 578-DX propfan, which was a prototype from the Allison Engine Company (a division of General Motors) that was also derived from the Allison XT701 and built with Hamilton Standard propellers. The engine program was jointly developed between Allison and another division of United Technologies, the engine maker Pratt & Whitney. Unlike the competing GE36 UDF, the 578-DX was fairly conventional, having a reduction gearbox between the LP turbine and the propfan blades. Due to jet fuel price drops and shifting marketing priorities, Douglas shelved the propfan program later that year.

Other proposed applications

Aside from the aircraft mentioned above, there were several other announcements of future propfan-powered airliners, such as:

- The Fokker FXX, a 100-120 seat propfan-powered aircraft that was studied in 1982[30]

- The MPC-75,[31] an 80-seat, Mach 0.76 cruise speed, 1,500 nmi range (1,700 mi; 2,800 km) regional aircraft conceived by Messerschmitt-Bölkow-Blohm (MBB) of West Germany and the Chinese Aero Technology Export/Import Corporation (CATIC), potentially using a geared propfan version of the Allison T406 tiltrotor engine providing 12,000 lbf (53 kN) of takeoff thrust[32], or a 9,000 lbf thrust (40 kN) unducted fan version of the General Electric GE38 engine[33]

- The ATR 92, a 400-knot cruising speed (460-mile-per-hour; 740-kilometre-per-hour), five- or six-abreast, 100-seat aircraft from Avions de Transport Regional (ATR, a joint venture between France's Aerospatiale and Italy's Aeritalia)[34] and Spain's Construcciones Aeronáuticas SA (CASA),[35] which would possibly be powered by the UDF[36]

- The Aerospatiale AS.100, an 80- to 100-seat aircraft that might be powered by the UDF[36] or by a propfan version of the Allison T406[35] tiltrotor engine

- The ATRA-90, a 100-seat aircraft built by the Advanced Technology Regional Aircraft (ATRA) multinational joint venture, which consisted of Industri Pesawat Terbang Nusantara (IPTN) of Indonesia, Boeing (USA), MBB (West Germany), and Fokker (Netherlands)[37]

- The Tupolev Tu-334, a 126-seat aircraft that can travel 1,860 nmi (2,140 mi; 3,450 km) with 11,430 kg payload (25,200 lb; 11.43 t; 12.60-short-ton), which is powered by two Progress (also known as Lotarev) D-236 propfans[38] with a specific fuel burn of 0.46 kg/kg-thrust/hour, a cruise thrust of 1.6 tonnes-force (3,500 lbf; 16 kN), and a static thrust of 8 to 9 tf (18,000 to 20,000 lbf; 78 to 88 kN)[39]

- The Ilyushin Il-88, a successor to the four-turboprop Antonov An-12 tactical transporter that would be powered by two 11,000 hp (8,200 kW) Progress D-236 propfans[40]

- The Ilyushin Il-118, an upgrade to the four-turboprop Ilyushin Il-18 airliner;[41] proposed in 1984, the aircraft would instead be powered by two D-236 propfans, with the eight-bladed front propeller on each engine rotating at a speed of 1,100 rpm and the six-bladed back propeller turning at 1,000 rpm to lower noise and vibration[42]

- A re-engined Antonov An-124, with the four Progress D-18T turbofans being replaced by 55,100 lbf thrust (245.2 kN) Kuznetsov NK-62 propfans[43]

Decline

None of these projects came to fruition, however, mainly because of excessive cabin noise (compared to turbofans) and low fuel prices.[44] For General Electric, the GE36 UDF was meant to replace the CFM56 high-bypass turbofan that it produced with equal partner Snecma in their CFM International joint venture, as in the 1980s the engine was initially uncompetitive against the International Aero Engines rival offering, the IAE V2500. In December 1986, the chairman of Snecma declared that the in-development CFM56-5S2 would be the last turbofan created for the CFM56 family, and that "There is no point in spending more money on turbofans. UDF is the future."[45] The V2500 ran into technical problems in 1987, however, and the CFM56 gained major sales momentum. General Electric became uninterested in having the GE36 cannibalize the CFM56, which also went five years before it received its first order in 1979, and while "the UDF could be made reliable by earlier standards, turbofans were getting much, much better than that." General Electric did add the UDF's blade technology directly into the GE90, the most powerful jet engine ever produced, for the Boeing 777.[46]

1990s–current

At the beginning of the 1990s, the Soviet Union/Russia performed flight tests on the Progress D-236, a geared contra-rotating propfan engine based on the core of the Progress D-36 turbofan, with eight blades on the front propeller and six blades on the back propeller. One testbed was a 10,100 hp (7,500 kW) propfan mounted to an Ilyushin Il-76 and flown to the Hannover ILA 90 airshow, which was intended for an unidentified four-propfan aircraft.[47] The D-236 flew 36 times for a total of 70 flight test hours on the Il-76.[48] The other testbed was a 10,990 hp (8,195 kW), 14 ft unit (4.2 m; 170 in; 420 cm) mounted to a Yakovlev Yak-42E-LL and flown to the 1991 Paris Air Show, as a demonstration for the planned Yak-46 aircraft with twin propfan engines,[49] which in its base 150-seat version would have a range of 1,900 nmi (2,200 mi; 3,500 km) and cruise at a speed of 460 kn (530 mph; 850 km/h; 780 ft/s; 240 m/s)[50] (Mach 0.75).[51] The Soviets claimed the D-236 had a true aerodynamic efficiency of 28 percent and a fuel savings of 30 percent over an equivalent turboprop. They also revealed plans for propfans with power ratings of 14,100 and 30,200 hp (10,500 and 22,500 kW).[47]

.jpg)

Like the Progress D-236, the more powerful Progress D-27 propfan engine is a contra-rotating propfan with eight front blades and six back blades,[51] but the D-27 has advanced composite blades with a reduced thickness-to-chord ratio and a more pronounced curvature at the leading edge.[52] An engine that was launched in 1985, the D-27[53] delivers 14,000 hp (10,440 kW) of power with 27,000 lbf (119 kN) of thrust at takeoff.[54] Two rear-mounted D-27 propfans propelled the Ukrainian Antonov An-180, which was scheduled for a 1995 first flight and a 1997 entry into service.[55] In January 1994, Antonov rolled out the first prototype of the An-70 military transport aircraft, powered by four Progress D-27s attached to wings mounted to the top of the fuselage.[54] The Russian Air Force placed an order for 164 aircraft in 2003, which was subsequently canceled. As of 2013, the An-70 was still thought to have a promising future as a freighter.[56] However, since the propeller component of the Progress D-27 is made by Russia's SPE Aerosila, the An-70 cannot be built because of Ukraine's political conflict with Russia. Instead, Antonov began working with Turkey in 2018 to redevelop the An-70 as the rebranded An-77, so that the aircraft can comply with modern-day requirements without Russian supplier participation.[57]

In the first decade of the 21st century, jet fuel prices began to rise again, and there was increased emphasis on engine/airframe efficiency to reduce emissions, which renewed interest in the propfan concept for jetliners that might come into service beyond the Boeing 787 and Airbus A350XWB. For instance, Airbus has patented aircraft designs with twin rear-mounted contra-rotating propfans.[58] While Rolls-Royce was lukewarm on propfan technology in the 1980s[59] (although it had the rear (pusher) configured RB.509-11 and front (tractor) configured RB.509-14 geared propfan designs, which produced 15,000–25,000 lbf thrust (6,800–11,300 kgf; 67–111 kN) using the gas generator from its XG-40 engine[60] with 13,000 hp (9,700 kW) of shaft power),[61] it had now developed an open rotor engine design that was thought to be a finalist for the new Irkut MS-21 narrowbody aircraft.[62] The Rolls-Royce RB3011 engine would have a diameter of about 170 in (430 cm; 14 ft; 4.3 m) and require a 16,000 shaft hp (12,000 kW) gearbox.[63]

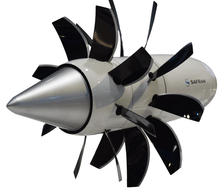

The European Commission launched in 2008 an Open Rotor demonstration led by Safran within the Clean Sky program with 65 million euros funding over eight years. A demonstrator was assembled in 2015, and ground tested in May 2017 on its open-air test rig in Istres, aiming to reduce fuel consumption and associated CO2 emissions by 30% compared with current CFM56 turbofans.[64] After the completion of ground testing at the end of 2017, Safran's geared open rotor engine had reached a technology readiness level of TRL 5.[65] The open rotor demonstrator's twelve-blade front propeller and ten-blade back propeller have diameters of 13.1 and 12.5 ft (4.0 and 3.8 m; 160 and 150 in; 400 and 380 cm), respectively. The demonstrator, which is based on the core of the Snecma M88 military fighter engine, uses up to 12,200 horsepower (9 megawatts), provides a thrust of about 22,000 lbf (100 kN), and would cruise at a speed of Mach 0.75.[66] Safran's future open rotor engine, however, would have a maximum diameter of almost 14.8 ft (4.50 m; 177 in; 450 cm).[67]

Limitations and solutions

Blade design

Turboprops have an optimum speed below about 450 mph (390 kn; 720 km/h),[68] because all propellers lose efficiency at high speed, due to an effect known as wave drag that occurs just below supersonic speeds. This powerful form of drag has a sudden onset, and it led to the concept of a sound barrier when first encountered in the 1940s. In the case of a propeller, this effect can happen any time the propeller is spun fast enough that the blade tips approach the speed of sound, even if the aircraft is motionless on the ground.

The most effective way to counteract this problem (to some degree) is by adding more blades to the propeller, allowing it to deliver more power at a lower rotational speed. This is why many World War II fighter designs started with two or three-blade propellers but by the end of the war were using up to five blades; as the engines were upgraded, new propellers were needed to more efficiently convert that power. The major downside to this approach is that adding blades makes the propeller harder to balance and maintain, and the additional blades cause minor performance penalties due to drag and efficiency issues. But even with these sorts of measures, eventually the forward speed of the plane combined with the rotational speed of the propeller blade tips (altogether known as the helical tip speed) will again result in wave drag problems. For most aircraft, this will occur at speeds over about 450 mph (390 kn; 720 km/h).

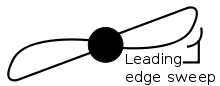

A method of decreasing wave drag was discovered by German researchers in 1935—sweeping the wing backwards. Today, almost all aircraft designed to fly much above 450 mph (390 kn; 720 km/h) use a swept wing. In the 1970s, Hamilton Standard started researching propellers with similar sweep. Since the inside of the propeller is moving slower in the rotational direction than the outside, the blade is progressively more swept back toward the outside, leading to a curved shape similar to a scimitar - a practice that was first used as far back as 1909, in the Chauvière two-bladed wood propeller used on the Blériot XI. (At the blade root, the blade is actually swept forward into the rotational direction, to counter the twisting that is generated by the backward swept blade tips.)[69] The Hamilton Standard test propfan was swept progressively to a 39-degree maximum at the blade tips, allowing the propfan to produce thrust even though the blades had a helical tip speed of about Mach 1.15.[70]

The blades of the GE36 UDF and the 578-DX have a maximum tip speed in rotation of about 750–800 feet per second (440–470 knots; 230–240 metres per second; 510–550 miles per hour; 820–880 kilometres per hour),[71] or about half the maximum tip speed for the propeller blades of a conventional turbofan.[72] That maximum blade tip speed would be kept constant if the engine designer chooses to widen or narrow the propeller diameter (resulting in an RPM reduction or increase, respectively).[3]

Drag can also be reduced by making the blades thinner, which increases the speed that the blades can attain before the air ahead of them becomes compressible and causes shock waves. For example, the blades of the Hamilton Standard test propfan had a thickness-to-chord ratio that tapered from less than twenty percent at the spinner junction to two percent at the tips, with the ratio being only four percent at mid-span.[70] Propfan blades had approximately half the thickness-to-chord ratio of the best conventional propeller blades of the era,[73] thinned to razor-like sharpness at their edges,[12][74] and weighed as little as 20 pounds (9.1 kg).[75] (The GE36 UDF engine that was tested on the Boeing 727 had front and back blades that weighed 22.5 and 21.5 lb (10.2 and 9.8 kg) each.)[76]

Noise

Jet aircraft fly faster than conventional propeller-driven aircraft. However, they use more fuel, so that for the same fuel consumption a propeller installation produces more thrust. As fuel costs become an increasingly important aspect of commercial aviation, engine designers continue to seek ways to improve aero engine efficiency. The propfan concept was developed to deliver 35% better fuel efficiency than contemporary turbofans. In static and air tests on a modified Douglas DC-9, propfans reached a 30% improvement over the OEM turbofans. This efficiency came at a price, as one of the major problems with the propfan is noise, particularly in an era where aircraft are required to comply with increasingly strict aircraft noise regulations. The propfan research in the 1980s discovered ways to reduce noise, but at the cost of reduced fuel efficiency, mitigating some of the advantages of a propfan.

General methods for reducing noise include lowering the blade tip speeds and decreasing the blade loading, or the amount of thrust per unit of blade surface area. A concept similar to wing loading, blade loading can be reduced by lowering the thrust requirement or by increasing the amount, chord (width), and/or span (length) of the blades. For contra-rotating propfans, which can be louder than turboprops or single-rotating propfans, noise can also be lowered by:[77]

- increasing the gap between the front propeller and the back propeller;

- making sure the blade lengths of the back propeller are shorter than those of the front propeller, so that the back propeller blades avoid cutting through the blade tip vortices of the front propeller (blade-vortex interaction);

- using a different number of blades on the front propeller compared to the back propeller, to avoid acoustic reinforcement; and

- turning the front propeller and back propeller at different rotational speeds, also to prevent acoustic reinforcement.[42]

Community noise

Engine makers expect propfan implementations to meet community (as opposed to cabin) noise regulations without sacrificing the efficiency advantage. Some think that propfan engines can potentially cause less of a community impact than turbofan engines, because the rotational speeds of a propfan are lower than that of a turbofan. Geared propfans should have an advantage over ungeared propfans for the same reason.[78]

In 2007, the Progress D-27 was successfully modified to meet the United States Federal Aviation Administration (FAA) Stage 4 regulations, which correspond to International Civil Aviation Organization (ICAO) Chapter 4 standards and were adopted in 2006.[79] A 2012 trade study projected that noise from existing open rotor technology would be 10–13 decibels quieter than the maximum noise level allowed by the Stage 4 regulations;[80] the newer Stage 5 noise limits (which replaced the Stage 4 regulations for larger aircraft in 2018 and mirrored the ICAO Chapter 14 noise standard established in 2014) are more restrictive than the Stage 4 requirement by only seven effective perceived noise decibels (EPNdB),[81] so current propfan technology shouldn't be hindered by the Stage 5 standards. The study also projected that at existing technology levels, open rotors would be nine percent more fuel-efficient but remain 10–12 decibels louder than turbofans.[80] Snecma, however, maintains that open-rotor tests show that its propfan engines would have about the same noise levels as its CFM LEAP turbofan engine,[82] which entered service in 2016.

Further reductions can be achieved by redesigning the aircraft structure to shield noise from the ground. For example, another study estimated that if propfan engines were used to power a hybrid wing body aircraft instead of a conventional tube-and-wing aircraft, noise levels could be reduced by as much as 38 EPNdB compared to ICAO Chapter 4 requirements.[83] In 2007, the British budget airline easyJet introduced its ecoJet concept, a 150-250 seat aircraft with V-mounted open rotor engines joined to the rear fuselage and shielded by a U-tail.[84] It unsuccessfully initiated discussions with Airbus, Boeing, and Rolls-Royce to produce the aircraft.[85]

Size

A twin-engine aircraft carrying 100–150 passengers would require propfan diameters of 120–168 inches (300–430 cm; 10.0–14.0 ft; 3.0–4.3 m),[70] and a propfan with a propeller diameter of 236 in (600 cm; 19.7 ft; 6.0 m) would theoretically produce almost 60,000 lbf (270 kN) of thrust.[86] These sizes achieve the desired high bypass ratios of over 30, but they are approximately twice the diameter of turbofan engines of equivalent capability.[66] For this reason, airframers usually design the empennage with a T-tail configuration for aerodynamic purposes, and the propfans may be attached to the upper part of the rear fuselage. For the Rolls-Royce RB3011 propfan prototype, a pylon of about 8.3 ft (2.54 m; 100 in; 254 cm) long would be required to connect the center of each engine to the side of the fuselage.[87] If the propfans are mounted to the wings, the wings would be attached to the aircraft in a high wing configuration, which allows for ground clearance without requiring excessively long landing gear. For the same amount of power or thrust produced, an unducted fan requires shorter blades than a geared propfan,[88] although the overall installation issues still apply.

Output rating

Turboprops and most propfans are rated by the amount of shaft horsepower (shp) that they produce, as opposed to turbofans and the UDF propfan type, which are rated by the amount of thrust they put out. This difference can be somewhat confusing when comparing different types of engines. The rule of thumb is that at sea level with a static engine, 1 shaft horsepower (750 watts) is roughly equivalent of 2 pounds-force (8.9 N) thrust, but at cruise altitude, that 1 shaft horsepower (750 watts) changes to about 1 pound-force (4.4 N) thrust. That means a narrowbody aircraft with two 25,000 lbf thrust (110 kN) engines can theoretically be replaced with a pair of 12,000–13,000 shaft hp (8,900–9,700 kW) propfans or with two 25,000 lbf thrust (110 kN) UDF propfans.[3]

Aircraft with propfans

See also

- Turboprop

- Contra-rotating propeller

- Contra-rotating

- Ducted fan

- Geared turbofan

Comparable engines

- Europrop TP400

- General Electric GE-36 UDF

- Kuznetsov NK-12

- Kuznetsov NK-93

- Metrovick F.5

- Pratt & Whitney/Allison 578-DX

- Progress D-27

- Progress D-236

- Rolls-Royce RB3011

Related lists

References

- US 4171183, Cornell, Robert W. & Carl Rohrbach, "Multi-bladed, high speed prop-fan", published 16 Oct 1979, assigned to United Technologies Corporation

- "What is propfan?". Flight International. January 16, 1982. p. 113. ISSN 0015-3710.

- "Propfan/UDF: some answers questioned". Paris Review. Flight International. June 15, 1985. pp. 8–9. Retrieved March 28, 2019.

- "Propfans—'the genie is out of the bottle'" (PDF). Air Transport. Flight International. 129 (3999). New Delhi, India. February 22, 1986. p. 8. Retrieved May 17, 2019.

- EASA 2015, pp. 5–6.

- El-Sayed, Ahmed F. (July 6, 2017). Aircraft propulsion and gas turbine engines (2nd ed.). CRC Press. Table 6.11. ISBN 9781466595187. OCLC 986784025.

- Kuntz et al., pp. 2 to 3.

- "Metrovick F.5: Open-fan thrust augmenter on standard F.2 gas generator". Flight. January 2, 1947. p. 18. Archived (PDF) from the original on November 7, 2017. Retrieved March 28, 2019.

- Kuntz et al., p. 3.

- Rohrbach, C.; Metzger, F. B. (September 29 – October 1, 1975). The Prop-Fan - A new look in propulsors. 11th Propulsion Conference. 75-1208. Anaheim, California: American Institute of Aeronautics and Astronautics (AIAA) and Society of Automotive Engineers (SAE). doi:10.2514/6.1975-1208.

- Ferrell, J. E. (October 12, 1986). "Propfan gets another whirl". San Francisco Examiner. Retrieved April 25, 2019 – via Chicago Tribune.

- Schefter, Jim (March 1985). "So long, jets? Ingenious new blades make propliners as fast as jets". Cover story. Popular Science. 226 (3). pp. 66–69. ISSN 0161-7370.

- Wilford, John Noble (August 24, 1982). "Sleek, high-performance designs give propellers a future after all". Science Times. New York Times. Edwards Air Force Base, California, USA. p. C1. ISSN 0362-4331.

- Rohrbach, Carl (July 26–29, 1976). A report on the aerodynamic design and wind tunnel test of a Prop-Fan model. 12th Propulsion Conference. 76-667. Palo Alto, California: American Institute of Aeronautics and Astronautics (AIAA) and Society of Automotive Engineers (SAE). doi:10.2514/6.1976-667. Lay summary.CS1 maint: date format (link)

- Jeracki, Robert J.; Mikkelson, Daniel C.; Blaha, Bernard J. (April 3–6, 1979). Wind tunnel performance of four energy efficient propellers designed for Mach 0.8 cruise. SAE Business Aircraft Meeting and Exposition. 790573. Wichita, Kansas: Society of Automotive Engineers (SAE). doi:10.4271/790573. hdl:2060/19790011898. OCLC 37181399. Lay summary.

- Goldsmith 1981.

- "Propfanned G2 takes to the air" (PDF). World News. Flight International. Vol. 131 no. 4061. Marietta, Georgia, USA. May 9, 1987. p. 2. ISSN 0015-3710.

- Searles, Robert A. (September 1–2, 1984). "Propfan engine development aims at cutting fuel costs". A Special Report on Aerospace. International Herald Tribune (31581). New York. p. 10. ISSN 0294-8052.

- "Gulfstream flies with propfan" (PDF). Propulsion. Flight International. 131 (4062). May 16, 1987. p. 16. ISSN 0015-3710.

- "Propfan acoustic tests completed" (PDF). Flight International. Vol. 133 no. 4114. May 21, 1988. p. 37. ISSN 0015-3710.

- Poland, D. T.; Bartel, H. W.; Brown, P. C. (July 11–13, 1988). PTA flight test overview. Joint Propulsion Conference (24th ed.). Boston, Massachusetts, USA. doi:10.2514/6.1988-2803. OCLC 1109689683.

- Rickley, E.J. (September 1989). En route noise: NASA propfan test aircraft (calculated source noise) (Report). Washington, D.C.: U.S. Department of Transportation (DOT) Federal Aviation Administration (FAA) Office of Environment. pp. 41–59. Lay summary.

- Garber, Donald P.; Willshire, William L. Jr. (September 1994). En route noise levels from Propfan Test Assessment airplane (Report). Hampton, Virginia: National Aeronautics and Space Administration (NASA). Lay summary.

- "NASA shuttle training aircraft". Texas Air & Space Museum. Retrieved July 18, 2019.

- GE Aircraft Engines 1987.

- "Manufacturers positioning for coming competitive battles". Air Transport World. No. September 1986. Farnborough, England, United Kingdom. pp. 20+. ISSN 0002-2543.

G.E., however, insisted that open rotors' efficiency drops off at a much higher speed. Gordon said Boeing has G.E.'s and its own results from UDF windtunnel tests up to Mach 0.9 and continues to list the UDF as the baseline engine on the 7J7 that has a design cruise speed of Mach 0.83. 'Boeing is not crazy,' he told ATW.

- "GE's UDF flies again" (PDF). Air Transport. Flight International. Vol. 130 no. 4027. Mojave, California, USA. September 6, 1986. p. 23. ISSN 0015-3710.

- "Propfans ready by 1990". Paris Report. Flight International. June 8, 1985. p. 5. Archived (PDF) from the original on September 25, 2014. Retrieved March 28, 2019.

- Warwick, Graham (August 15, 1987). "UHB: the acid test". Flight International. pp. 22–23. Retrieved March 22, 2019.

- "Delta demands 150-seater as MDF-100 dies" (PDF). Air transport. Flight International. Vol. 121 no. 3798. February 20, 1982. p. 404. ISSN 0015-3710.

- MPC 75 feasibility study — summary report (PDF) (Report). July 1987. p. B1-10.

- Middleton, Peter (April 8, 1989). "MPC gears up: The joint-venture MPC company, formed recently by MBB and the Chinese Government, is now actively defining the MPC75 airliner project in preparation for a decision to go-ahead at the end of 1990". Flight International. Vol. 135 no. 4159. Hamburg, Germany. pp. 19–21. ISSN 0015-3710.

- "Family power". Flight International. July 29, 1989. pp. 26–27.

- "ATR plans 100-seater" (PDF). Farnborough First News. Flight International. Farnborough, England, United Kingdom. September 10, 1988. p. 16. ISSN 0015-3710.

- Sedbon, Gilbert (December 17, 1988). "Spain joins 'ATR 92' study" (PDF). Flight International. Paris, France. p. 14. ISSN 0015-3710.

- "Snecma raises propfan funds". Air Transport. Flight International. Vol. 132 no. 4086. Paris, France. October 31, 1987. p. 6. ISSN 0015-3710.

- "Propfan project on hold" (PDF). Flight International. Vol. 133 no. 4115. May 28, 1988. p. 7. ISSN 0015-3710.

- "TU-134 replacement decision due". Moscow Aerospace '90. Flight International. Vol. 138 no. 4237. October 10–16, 1990. p. 28. ISSN 0015-3710.

- Postlethwaite, Alan (April 29, 1989). "Tupolev unveils propfan airliner". Flight International. Vol. 135 no. 4162. Moscow, Soviet Union. p. 10. ISSN 0015-3710.

- "Ilyushin Il-276 (SVTS)". Ruslet: Great Encyclopedia of Russian and Chinese Aviation (in Russian). Retrieved April 23, 2019.

- "Ilyushin IL-18 (Coot): Turboprop-powered passenger airliner / maritime reconnaissance platform". Archived from the original on March 9, 2019. Retrieved April 23, 2019.

- Gordon, Yefim; Komissarov, Dmitriy (2003). Ilyushin IL-18/-20/-22: A versatile turboprop transport. Aerofax. p. 47. ISBN 9781857801576. OCLC 52195311.

- "NK-62, NK-63 - Kuznetsov, USSR" (in Czech).

- Flight International (2007-07-12). "Whatever happened to propfans?". Archived from the original on October 20, 2007. Retrieved January 28, 2019.

- "France backs UDF". Propulsion. Flight International. Vol. 130 no. 4042. Villaroche, France. December 20, 1986. p. 63. ISSN 0015-3710.

- Sweetman, Bill (September 2005). "The short, happy life of the Prop-fan: Meet the engine that became embroiled in round one of Boeing v. Airbus, a fight fueled by the cost of oil". Air & Space/Smithsonian Magazine. 20 (3). pp. 42–49. ISSN 0886-2257. OCLC 109549426. Archived from the original on August 14, 2017. Retrieved January 28, 2019.

- "Soviets show Il-76 mounted 'propfan'". Flight International. Vol. 137 no. 4217. May 23–29, 1990. p. 9. ISSN 0015-3710.

- Komissarov, Dmitriy; Gordon, Yefim (2001). Ilyushin IL-76: Russia's versatile airlifter. Aerofax. pp. 43–45. ISBN 9781857801064. OCLC 47676935.

- "Yak propfan pops into Paris". Paris Show Report. Flight International. Vol. 140 no. 4272. June 26 – July 2, 1991. p. 16. ISSN 0015-3710.

- Rybak, Boris (May 22–28, 1991). "Yakovlev takes propfan lead: While development of fuel-saving propfan engines languishes in the West, work continues in the Soviet Union where recent fuel shortages have underscored the need for new engine technology". Commercial Engines. Flight International. Vol. 139 no. 4267. pp. 27–28. ISSN 0015-3710.

- Postlethwaite, Alan (May 9–15, 1990). "Yakovlev strikes back: Propfan and other high-technology derivatives of the Yak-42 airliner (NATO codename Clobber) are planned". Flight International. Vol. 137 no. 4215. pp. 61–62, 65–66. ISSN 0015-3710.

- "More detailed information about D-27 engine". SE Ivchenko-Progress. Archived from the original on 2013-01-26. Retrieved 2012-06-29.

- Dmytriyev, Sergiy (October 12–14, 2015). Ivchenko-Progress innovations for turboprop engines (PDF). 5th Symposium on Collaboration in Aircraft Design. Naples, Italy. Archived (PDF) from the original on April 19, 2019.

- Velovich, Alexander (February 9–15, 1994). "Against all odds: Despite having to toil in a cold economic climate, Antonov has rolled out the first of what it hopes will be many of its An-70 four-engine transport aircraft". Antonov An-70. Flight International. Vol. 145 no. 4407. pp. 34–35. ISSN 0015-3710.

- "An-180 project by ANTK O.K.Antonov".

- "Freighter of the future?". Air Cargo World. February 15, 2013.

- "Manufacturers news" (PDF). Civil News. Scramble. No. 471. Dutch Aviation Society. August 2018. p. 38. Archived from the original (PDF) on May 2, 2019.

- US application 2009020643, Airbus & Christophe Cros, "Aircraft having reduced environmental impact", published 2009-01-22

- Colchester, Nicholas (March 24, 1986). "Elegance is key to cut and thrust". Technology. Financial Times. p. 12.

- Alekseyev, Col. Yu. (1988). "Propfan engines". Zarubezhnoye Voyennoye Obozreniye. Moscow: Soviet Union Ministry of Defense (published March 21, 1989) (10): 27–29. OCLC 946659244 – via Soviet Union Foreign Military Review.

- "United Kingdom aerospace and weapons projects: Gas turbines". Archived from the original on March 5, 2013. Retrieved April 30, 2019.

- Karnozov, Vladimir (September 3, 2008). "Yakovlev ready to call for MS-21 systems tenders as design freeze nears". Flight International. Moscow, Russia.

- Butterworth-Hayes, Philip (March 2010). "Open rotor research revs up" (PDF). Aerospace America. Vol. 48 no. 3. pp. 38–42. ISSN 0740-722X. OCLC 664005753. Archived from the original (PDF) on April 2, 2015.

- "Safran celebrates successful start of Open Rotor demonstrator tests on new open-air test rig in southern France" (Press release). Safran. October 3, 2017. Archived from the original on August 29, 2018. Retrieved October 3, 2017.

- Angrand, Antony (May 10, 2019). "Safran ponders open rotor options". Air & Cosmos International. No. 7. pp. 22–23. ISSN 1240-3113. Lay summary.

- Ebner, Ulrike (February 14, 2018). "Treibstoff-sparwunder: Open rotor". Flug Revue (in German). Archived from the original on March 29, 2019.

- Cueille, Stéphane (March 25, 2019). "What does the future hold in store for the Open Rotor?". Archived from the original on March 29, 2019. Retrieved March 29, 2019 – via Safran.

- Spakovszky, Zoltan (2009). "Unified propulsion lecture 1". Unified Engineering Lecture Notes. MIT. Archived from the original on March 31, 2018. Retrieved 2009-04-03.

- Garrison, Peter (February 1990). "Props and circumstance". Technicalities. Flying. Vol. 117 no. 2.

- Hammitt, Tom (June 1985). "Ace of blades: Their radical shapes hiding a conservative streak, propfans could combine fanjet speed with propeller efficiency". Flying. 112 (6). pp. 66–68, 70. Retrieved March 28, 2019.

- "Date set for Allison UHB flight test". Propulsion. Flight International. Long Beach, California, USA. February 8, 1986. pp. 50–51. Archived from the original on March 27, 2019. Retrieved March 28, 2019.

- "The fans are flying". Farnborough Report. Flight International. September 13, 1986. pp. 18, 20. Retrieved March 25, 2019.

- Hager & Vrabel 1988, p. 6.

- Nesbitt, Jim (September 22, 1985). "Jet engines propel into new era". Orlando Sentinel. Marietta, Georgia, USA. Archived from the original on March 30, 2019. Retrieved March 29, 2019.

- Moll, Nigel (May 1987). "7J7: The next new Boeing". Flying. pp. 37, 39.

- GE Aircraft Engines 1987, p. 163.

- Hager & Vrabel 1988, p. 82.

- Warwick, Graham; Moxon, Julian (May 23, 1987). "The power of persuasion". Flight International. Washington, DC, USA. pp. 39–41.

- Karnozov, Vladimir (May 1, 2007). "Military engines: Development thrusts". Flight International. Moscow, Russia. ISSN 0015-3710. Archived from the original on April 2, 2016.

- Croft, John (July 5, 2012). "Open rotor noise not a barrier to entry: GE". Flight International. Archived from the original on July 18, 2012. Retrieved July 21, 2012.

- Spencer, Jessica C. (October 25, 2017). "Stage 5 aircraft noise standards approved in US – what does it mean for airports?". Archived from the original on March 28, 2019. Retrieved March 28, 2019.

- Eshel, Tamir (January 2, 2014). "Snecma tests open rotor engine". Defense Update. Archived from the original on July 3, 2017. Retrieved April 10, 2019.

- Trimble, Stephen (February 12, 2014). "Analysis: Noise goals in sight for open-rotor researchers". News. Flight International. Washington, D. C., USA. p. 28. ISSN 0015-3710.

- "The 'easyJet ecoJet' to cut CO2 emissions by 50% by 2015". easyJet airline company ltd. Archived from the original on June 16, 2007. Retrieved December 30, 2017.

- Robinson, Tim (October 6, 2017). "Can easyJet short circuit electric airliner flight?". Royal Aeronautical Society.

- Learmount, David (August 30, 1986). "US air transport technology: where next?". Flight International. pp. 120–122, 124, 128. Retrieved March 28, 2019.

- Doyle, Andrew (October 5, 2009). "Keeping options open". Flight International. London, England, United Kingdom.

- Banks, Howard (May 7, 1984). "The next step: Jets drove propellers from the skies. But radical designs are bringing props back, creating engines that promise jetlike speeds and enormous fuel savings" (PDF). Forbes. pp. 31–33 – via NASA Langley Research Center Geographic Information Systems (GIS) Team.

General resources

- Prop fan propulsion concepts: Technology Review, Design Methodology, State-of-the-art designs and future outlook. Raymond Scott Ciszek. University of Virginia Department of Mechanical and Aerospace Engineering. Senior Thesis Project. March 25, 2002

Bibliography

- Dubois, Thierry; Warwick, Graham (January 9–22, 2017). "Last of the CRORs: Safran is about to test a counter-rotating open rotor engine, despite waning appeal". Advanced Propulsion. Aviation Week & Space Technology. Vol. 179 no. 1. Lyon, France and Washington, D.C., USA. p. 54. OCLC 969306167.

- Kinney, Jeremy R. (2017). "4: The Quest for Propulsive Efficiency, 1976–1989" (PDF). The power for flight: NASA's contributions to aircraft propulsion. NASA aeronautics book series. 631. pp. 114–125. hdl:2060/20180003207. ISBN 9781626830370. OCLC 990183146. Lay summary.CS1 maint: ref=harv (link)

- Notice of proposed amendment (NPA) 2015-22: Open rotor engine and installation (PDF), European Aviation Safety Agency, December 21, 2015, archived (PDF) from the original on August 25, 2018, retrieved March 28, 2019

- Khalid, S. Arif; Lurie, David; Breeze-Stringfellow, Andrew; Wood, Trevor; Ramakrishnan, Kishore; Paliath, Umesh; Wojno, John; Janardan, Bangalore; Goerig, Trevor; Opalski, Anthony; Barrett, Jack (May 2013). "FAA CLEEN program open rotor aeroacoustic technology non-proprietary report" (PDF). Federal Aviation Administration. General Electric. Archived (PDF) from the original on 8 July 2018. Retrieved 8 July 2018.CS1 maint: ref=harv (link)

- Coniglio, Sergio (February 2010). "Military aircraft propulsion: Jets vs. props". Military Technology (MILTECH). Vol. 34 no. 2. Mönch Publishing Group. pp. 77–84. ISSN 0722-3226. OCLC 527912380.

- Bowles, Mark (2010). "Advanced turboprops and laminar flow" (PDF). The Apollo of aeronautics: NASA's aircraft energy efficiency program, 1973-1987. NASA-SP. 2009-574. Washington, D.C.: National Aeronautics and Space Administration. pp. 122–136. hdl:2060/20110011568. ISBN 9780160842955. OCLC 465190382. Retrieved 25 September 2018. Lay summary.CS1 maint: ref=harv (link)

- Doyle, Andrew (October 6, 2009). "Open rotor: how does it work?". Flight International. London, England, UK. ISSN 0015-3710.

- Turner, Aimée (March 23, 2009). "Back to the windtunnel". Flight International. London, England, United Kingdom.

- "EU explores cleaner airplanes". Farnborough Air Show. AINonline. July 24, 2008.

- Bowles, Mark D.; Dawson, Virginia P. (1998). "Chapter 14: The advanced turboprop project: Radical innovation in a conservative environment". In Mack, Pamela (ed.). From engineering science to big science: The NACA and NASA Collier Trophy research project winners. NASA-SP. 4219. pp. 321–343. hdl:2060/20000012419. ISBN 978-0-16-049640-0. OCLC 757401658. Retrieved 25 September 2018. Lay summary.CS1 maint: ref=harv (link)

- Kuznetsov, N. D. (June 28–30, 1993). Propfan engines. Joint Propulsion Conference and Exhibit (29th ed.). Monterey, California, USA. doi:10.2514/6.1993-1981.

- Kuntz, H. L.; Gatineau, R. J.; Prydz, R. A.; Balena, F. J. (October 1991). Development and testing of cabin sidewall acoustic resonators for the reduction of cabin tone levels in propfan-powered aircraft (Report). OCLC 976747507. Lay summary.CS1 maint: ref=harv (link)

- Kuntz, H. L.; Gatineau, R. J. (May 1991). Laboratory test and acoustic analysis of cabin treatment for Propfan Test Assessment aircraft (Report). OCLC 27904451. Lay summary.CS1 maint: ref=harv (link)

- United States Environmental Protection Agency (EPA) (August 1990). Preliminary technology cost estimates of measures available to reduce U.S. greenhouse gas emissions by 2010 (Report). Attachment D: Memo from Michael Kavanaugh on UDF aircraft engine.

- Postlethwaite, Alan (April 18–24, 1990). "Opening doors: The Soviet aerospace industry is in transition as military cuts hit and its factories start producing consumer goods". Flight International. pp. 28–31.

- Little, B. H.; Poland, D. T.; Bartel, H. W.; Withers, C. C.; Brown, P. C. (July 1989). Propfan test assessment (PTA): Final project report. NASA-CR-185138. hdl:2060/19900002423. OCLC 891598373. Lay summary.CS1 maint: ref=harv (link)

- Little, B. H.; Barrel, H. W.; Reddy, N. N.; Swift, G.; Withers, C. C.; Brown, P. C. (April 1989). Propfan test assessment (PTA): Flight test report. NASA-CR-182278. hdl:2060/19900002422. OCLC 57716217. Lay summary.CS1 maint: ref=harv (link)

- "Douglas holds back on propfan launch" (PDF). Flight International. Vol. 134 no. 4127. August 20, 1988. p. 12.

- DeGeorge, C. L. (1988). Large-scale advanced prop-fan (LAP): Final report. NASA-CR-182112. hdl:2060/19880010922. OCLC 23092598. Lay summary.CS1 maint: ref=harv (link)

- Hager, Roy V.; Vrabel, Deborah (1988). Advanced turboprop project. NASA SP-495. Lewis Research Center, Cleveland, Ohio: National Aeronautics and Space Administration (NASA) Scientific and Technical Information Division. hdl:2060/19890003194. OCLC 17508419. Archived (PDF) from the original on March 13, 2017. Retrieved February 2, 2019. Lay summary.CS1 maint: ref=harv (link)

- GE Aircraft Engines (December 1987). Full scale technology demonstration of a modern counterrotating unducted fan engine concept. Design report. hdl:2060/19900000732. OCLC 1013402936 – via Internet Archive. Lay summary.CS1 maint: ref=harv (link)

- Donne, Michael (September 5, 1986). "The new aero-engines: A path to cheaper flight". Financial Times. Farnborough, England, United Kingdom. p. 20.

- Moxon, Julian (May 24, 1986). "After the big turbofans". Civil Propulsion. Flight International. Vol. 129 no. 4012. pp. 32, 34. ISSN 0015-3710.

- Skipp, Peter (December 14, 1985). "Tupolev and the new generation: Alexei Tupolev is looking ahead to a replacement for the Tu-154, the USSR's most widely-used short-to-medium-range jet airliner. He is also seeing into service a 154 derivative which will operate for many years to come". Flight International. pp. 30–31.

- Whitlow, J. B., Jr.; Sievers, G. K. (September 10–11, 1984). Fuel savings potential of the NASA advanced turboprop program. Aviation Fuel Conservation Symposium. Federal Aviation Administration (FAA). Washington, D. C., USA. hdl:2060/19840021809. OCLC 11694598. Lay summary.CS1 maint: ref=harv (link)

- "Soviet designers look ahead". Flight International. February 13, 1982. p. 335.

- Moxon, Julian (January 16, 1982). "Propfan: The propeller to replace jets?". Flight International. Windsor Locks, Connecticut, USA. pp. 112–114. ISSN 0015-3710.

- Goldsmith, I. M. (February 1981). A study to define the research and technology requirements for advanced turbo/propfan transport aircraft. NASA-CR-166138. hdl:2060/19820010328. Lay summary.CS1 maint: ref=harv (link)

External links

- Variable pitch propfan. NASA Lewis Educational TV (Television production). 1987.

- "Keith Henry archives collection: Prop-fan noise reduction and prop-fan propulsion research". NASA Cultural Resources (CRGIS). Retrieved April 25, 2019.

- Aguilar, Hector; Haan, Leon de; Knuyt, Jerry; Nieuwendijk, Lisa (December 2017). "Propfan, an alternative for turbofan engines: Tackling the technical design characteristics of a propfan" (PDF). AviationFacts.eu. Aviation Academy at the Amsterdam University of Applied Sciences (AUAS). Archived (PDF) from the original on 9 October 2018. Retrieved 9 October 2018.

- Norris, Guy (June 12, 2007). "Green sky thinking - carbon credits and the propfan comeback?". Flight International. ISSN 0015-3710. Archived from the original on June 21, 2007. Retrieved January 28, 2019.

- Sandru, Mike (October 27, 2008). "A new 'open rotor' jet engine that could reduce fuel consumption". The Green Optimistic. Archived from the original on December 17, 2018. Retrieved January 28, 2019.