Ultimate tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or Ftu within equations,[1][2][3] is the capacity of a material or structure to withstand loads tending to elongate, as opposed to compressive strength, which withstands loads tending to reduce size. In other words, tensile strength resists tension (being pulled apart), whereas compressive strength resists compression (being pushed together). Ultimate tensile strength is measured by the maximum stress that a material can withstand while being stretched or pulled before breaking. In the study of strength of materials, tensile strength, compressive strength, and shear strength can be analyzed independently.

Some materials break very sharply, without plastic deformation, in what is called a brittle failure. Others, which are more ductile, including most metals, experience some plastic deformation and possibly necking before fracture.

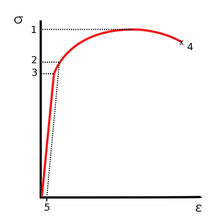

The UTS is usually found by performing a tensile test and recording the engineering stress versus strain. The highest point of the stress–strain curve (see point 1 on the engineering stress–strain diagrams below) is the UTS. It is an intensive property; therefore its value does not depend on the size of the test specimen. However, it is dependent on other factors, such as the preparation of the specimen, the presence or otherwise of surface defects, and the temperature of the test environment and material.

Tensile strengths are rarely used in the design of ductile members, but they are important in brittle members. They are tabulated for common materials such as alloys, composite materials, ceramics, plastics, and wood.

Tensile strength can be defined for liquids as well as solids under certain conditions. For example, when a tree[4] draws water from its roots to its upper leaves by transpiration, the column of water is pulled upwards from the top by the cohesion of the water in the xylem, and this force is transmitted down the column by its tensile strength. Air pressure, osmotic pressure, and capillary tension also plays a small part in a tree's ability to draw up water, but this alone would only be sufficient to push the column of water to a height of less than ten metres, and trees can grow much higher than that (over 100 m).

Tensile strength is defined as a stress, which is measured as force per unit area. For some non-homogeneous materials (or for assembled components) it can be reported just as a force or as a force per unit width. In the International System of Units (SI), the unit is the pascal (Pa) (or a multiple thereof, often megapascals (MPa), using the SI prefix mega); or, equivalently to pascals, newtons per square metre (N/m²). A United States customary unit is pounds per square inch (lb/in² or psi), or kilo-pounds per square inch (ksi, or sometimes kpsi), which is equal to 1000 psi; kilo-pounds per square inch are commonly used in one country (US), when measuring tensile strengths.

Concept

Ductile materials

1. Ultimate strength

2. Yield strength

3. Proportional limit stress

4. Fracture

5. Offset strain (typically 0.2%)

- 1: Ultimate strength

- 2: Yield strength (yield point)

- 3: Rupture

- 4: Strain hardening region

- 5: Necking region

- A: Apparent stress (F/A0)

- B: Actual stress (F/A)

Many materials can display linear elastic behavior, defined by a linear stress–strain relationship, as shown in figure 1 up to point 3. The elastic behavior of materials often extends into a non-linear region, represented in figure 1 by point 2 (the "yield point"), up to which deformations are completely recoverable upon removal of the load; that is, a specimen loaded elastically in tension will elongate, but will return to its original shape and size when unloaded. Beyond this elastic region, for ductile materials, such as steel, deformations are plastic. A plastically deformed specimen does not completely return to its original size and shape when unloaded. For many applications, plastic deformation is unacceptable, and is used as the design limitation.

After the yield point, ductile metals undergo a period of strain hardening, in which the stress increases again with increasing strain, and they begin to neck, as the cross-sectional area of the specimen decreases due to plastic flow. In a sufficiently ductile material, when necking becomes substantial, it causes a reversal of the engineering stress–strain curve (curve A, figure 2); this is because the engineering stress is calculated assuming the original cross-sectional area before necking. The reversal point is the maximum stress on the engineering stress–strain curve, and the engineering stress coordinate of this point is the ultimate tensile strength, given by point 1.

The UTS is not used in the design of ductile static members because design practices dictate the use of the yield stress. It is, however, used for quality control, because of the ease of testing. It is also used to roughly determine material types for unknown samples.[5]

The UTS is a common engineering parameter to design members made of brittle material because such materials have no yield point.[5]

Testing

Typically, the testing involves taking a small sample with a fixed cross-sectional area, and then pulling it with a tensometer at a constant strain (change in gauge length divided by initial gauge length) rate until the sample breaks.

When testing some metals, indentation hardness correlates linearly with tensile strength. This important relation permits economically important nondestructive testing of bulk metal deliveries with lightweight, even portable equipment, such as hand-held Rockwell hardness testers.[6] This practical correlation helps quality assurance in metalworking industries to extend well beyond the laboratory and universal testing machines.

While most metal forms, such as sheet, bar, tube, and wire, can exhibit the test UTS, fibers, such as carbon fibers, being only 2/10,000th of an inch in diameter, must be made into composites to create useful real-world forms. As the datasheet on T1000G below indicates, while the UTS of the fiber is very high at 6,370 MPa, the UTS of a derived composite is 3,040 MPa – less than half the strength of the fiber.[7]

Typical tensile strengths

| Material | Yield strength (MPa) | Ultimate tensile strength (MPa) | Density (g/cm³) |

|---|---|---|---|

| Steel, structural ASTM A36 steel[8] | 250 | 400–550 | 7.8 |

| Steel, 1090 mild | 247 | 841 | 7.58 |

| Chromium-vanadium steel AISI 6150 | 620 | 940 | 7.8 |

| Human skin | 15 | 20 | 2 |

| Steel, 2800 Maraging steel[9] | 2617 | 2693 | 8.00 |

| Steel, AerMet 340[10] | 2160 | 2430 | 7.86 |

| Steel, Sandvik Sanicro 36Mo logging cable precision wire[11] | 1758 | 2070 | 8.00 |

| Steel, AISI 4130, water quenched 855 °C (1570 °F), 480 °C (900 °F) temper[12] | 951 | 1110 | 7.85 |

| Steel, API 5L X65[13] | 448 | 531 | 7.8 |

| Steel, high strength alloy ASTM A514 | 690 | 760 | 7.8 |

| Acrylic, clear cast sheet (PMMA)[14] | 72 | 87[15] | 1.16 |

| High-density polyethylene (HDPE) | 26–33 | 37 | 0.85 |

| Polypropylene | 12–43 | 19.7–80 | 0.91 |

| Steel, stainless AISI 302 – cold-rolled | 520 | 860 | 8.19 |

| Cast iron 4.5% C, ASTM A-48 | 130 | 200 | 7.3 |

| "Liquidmetal" alloy | 1723 | 550–1600 | 6.1 |

| Beryllium[16] 99.9% Be | 345 | 448 | 1.84 |

| Aluminium alloy[17] 2014-T6 | 414 | 483 | 2.8 |

| Polyester resin (unreinforced)[18] | 55 | 55 | |

| Polyester and chopped strand mat laminate 30% E-glass[18] | 100 | 100 | |

| S-Glass epoxy composite[7] | 2358 | 2358 | |

| Aluminium alloy 6061-T6[19] | 270 | 310 | 2.7 |

| Copper 99.9% Cu[20] | 69 | 220 | 8.92 |

| Cupronickel 10% Ni, 1.6% Fe, 1% Mn, balance Cu | 130 | 350 | 8.94 |

| Brass | 200 + | 500 | 8.73 |

| Tungsten | 941 | 1510 | 19.25 |

| Glass | 33[21] | 2.53 | |

| E-Glass | N/A | 1500 for laminates, 3450 for fibers alone | 2.57 |

| S-Glass | N/A | 4710 | 2.48 |

| Basalt fiber[22] | N/A | 4840 | 2.7 |

| Marble | N/A | 15 | 2.6 |

| Concrete | N/A | 2–5 | 2.7 |

| Carbon fiber | N/A | 1600 for laminates, 4137 for fibers alone | 1.75 |

| Carbon fiber (Toray T1100G)[23] (the strongest man-made fibres) | 7000 fibre alone | 1.79 | |

| Human hair | 140–160 | 200–250[24] | |

| Bamboo | 350–500 | 0.4 | |

| Spider silk (see note below) | 1000 | 1.3 | |

| Spider silk, Darwin's bark spider[25] | 1652 | ||

| Silkworm silk | 500 | 1.3 | |

| Aramid (Kevlar or Twaron) | 3620 | 3757 | 1.44 |

| UHMWPE[26] | 24 | 52 | 0.97 |

| UHMWPE fibers[27][28] (Dyneema or Spectra) | 2300–3500 | 0.97 | |

| Vectran | 2850–3340 | ||

| Polybenzoxazole (Zylon)[29] | 2700 | 5800 | 1.56 |

| Wood, pine (parallel to grain) | 40 | ||

| Bone (limb) | 104–121 | 130 | 1.6 |

| Nylon, molded, type 6/6 | 450 | 750 | 1.15 |

| Nylon fiber, drawn[30] | 900[31] | 1.13 | |

| Epoxy adhesive | – | 12–30[32] | – |

| Rubber | – | 16 | |

| Boron | N/A | 3100 | 2.46 |

| Silicon, monocrystalline (m-Si) | N/A | 7000 | 2.33 |

| Ultra-pure silica glass fiber-optic strands[33] | 4100 | ||

| Sapphire (Al2O3) | 400 at 25 °C, 275 at 500 °C, 345 at 1000 °C | 1900 | 3.9–4.1 |

| Boron nitride nanotube | N/A | 33000 | 2.62[34] |

| Diamond | 1600 | 2800 | 3.5 |

| Graphene | N/A | 130000[35] | 1.0 |

| First carbon nanotube ropes | ? | 3600 | 1.3 |

| Colossal carbon tube | N/A | 7000 | 0.116 |

| Carbon nanotube (see note below) | N/A | 11000–63000 | 0.037–1.34 |

| Carbon nanotube composites | N/A | 1200[36] | N/A |

| High-strength carbon nanotube film | N/A | 9600[37] | N/A |

| Iron (pure mono-crystal) | 3 | 7.874 | |

| Limpet Patella vulgata teeth (Goethite) | 4900 3000–6500[38] |

||

- ^a Many of the values depend on manufacturing process and purity or composition.

- ^b Multiwalled carbon nanotubes have the highest tensile strength of any material yet measured, with labs producing them at a tensile strength of 63 GPa,[39] still well below their theoretical limit of 300 GPa. The first nanotube ropes (20 mm in length) whose tensile strength was published (in 2000) had a strength of 3.6 GPa.[40] The density depends on the manufacturing method, and the lowest value is 0.037 or 0.55 (solid).[41]

- ^c The strength of spider silk is highly variable. It depends on many factors including kind of silk (Every spider can produce several for sundry purposes.), species, age of silk, temperature, humidity, swiftness at which stress is applied during testing, length stress is applied, and way the silk is gathered (forced silking or natural spinning).[42] The value shown in the table, 1000 MPa, is roughly representative of the results from a few studies involving several different species of spider however specific results varied greatly.[43]

- ^d Human hair strength varies by ethnicity and chemical treatments.

| Element | Young's modulus (GPa) | Offset or yield strength (MPa) | Ultimate strength (MPa) |

|---|---|---|---|

| silicon | 107 | 5000–9000 | |

| tungsten | 411 | 550 | 550–620 |

| iron | 211 | 80–100 | 350 |

| titanium | 120 | 100–225 | 246–370 |

| copper | 130 | 117 | 210 |

| tantalum | 186 | 180 | 200 |

| tin | 47 | 9–14 | 15–200 |

| zinc alloy | 85–105 | 200–400 | 200–400 |

| nickel | 170 | 140–350 | 140–195 |

| silver | 83 | 170 | |

| gold | 79 | 100 | |

| aluminium | 70 | 15–20 | 40–50 |

| lead | 16 | 12 |

See also

References

- ↑ "Generic MMPDS Mechanical Properties Table". stressebook.com. 6 December 2014. Archived from the original on 1 December 2017. Retrieved 27 April 2018.

- ↑ Degarmo, Black & Kohser 2003, p. 31

- ↑ Smith & Hashemi 2006, p. 223

- ↑ For a review, see Harvey Brown "The theory of the rise of sap in Trees: Some Historical and Conceptual Remarks" in Physics in Perspective vol 15 (2013) pp. 320–358

- 1 2 "Tensile Properties". Archived from the original on 16 February 2014. Retrieved 20 February 2015.

- ↑ E.J. Pavlina and C.J. Van Tyne, "Correlation of Yield Strength and Tensile Strength with Hardness for Steels", Journal of Materials Engineering and Performance, 17:6 (December 2008)

- 1 2 "Properties of Carbon Fiber Tubes". Archived from the original on 24 February 2015. Retrieved 20 February 2015.

- ↑ "ASTM A36 Grade Shape structural shape Steel - Matmatch". matmatch.com. Retrieved 2018-06-08.

- ↑ "MatWeb – The Online Materials Information Resource". Archived from the original on 15 December 2013. Retrieved 20 February 2015.

- ↑ "MatWeb – The Online Materials Information Resource". Archived from the original on 21 February 2015. Retrieved 20 February 2015.

- ↑ "MatWeb – The Online Materials Information Resource". Archived from the original on 21 February 2015. Retrieved 20 February 2015.

- ↑ "MatWeb – The Online Materials Information Resource". Archived from the original on 28 March 2017. Retrieved 20 February 2015.

- ↑ "USStubular.com". Archived from the original on 13 July 2009. Retrieved 27 June 2009.

- ↑ Archived 23 March 2014 at the Wayback Machine.IAPD Typical Properties of Acrylics

- ↑ strictly speaking this figure is the flexural strength (or modulus of rupture), which is a more appropriate measure for brittle materials than "ultimate strength."

- ↑ "MatWeb – The Online Materials Information Resource". Archived from the original on 21 February 2015. Retrieved 20 February 2015.

- ↑ "MatWeb – The Online Materials Information Resource". Archived from the original on 21 February 2015. Retrieved 20 February 2015.

- 1 2 "Guide to Glass Reinforced Plastic (fibreglass) – East Coast Fibreglass Supplies". Archived from the original on 16 February 2015. Retrieved 20 February 2015.

- ↑ "6061-T6 Aluminium Wrought Aluminium - Matmatch". matmatch.com. Retrieved 2018-06-08.

- ↑ "OS050 C11000 Copper Wrought Copper - Matmatch". matmatch.com. Retrieved 2018-06-08.

- ↑ "Soda-Lime (Float) Glass Material Properties :: MakeItFrom.com". Archived from the original on 3 July 2011. Retrieved 20 February 2015.

- ↑ "Basalt Continuous Fibers". Archived from the original on 29 December 2009. Retrieved 29 December 2009.

- ↑ "Toray Properties Document". Retrieved 17 September 2018.

- ↑ "Tensile Testing Hair". instron.us. Archived from the original on 28 September 2017.

- ↑ Agnarsson, I; Kuntner, M; Blackledge, TA (2010). "Bioprospecting Finds the Toughest Biological Material: Extraordinary Silk from a Giant Riverine Orb Spider". PLoS ONE. 5: e11234. Bibcode:2010PLoSO...511234A. doi:10.1371/journal.pone.0011234. PMC 2939878. PMID 20856804.

- ↑ Oral, E; Christensen, SD; Malhi, AS; Wannomae, KK; Muratoglu, OK (2006). "PubMed Central, Table 3:". J Arthroplasty. 21: 580–91. doi:10.1016/j.arth.2005.07.009. PMC 2716092. PMID 16781413. Archived from the original on 27 April 2018. Retrieved 20 February 2015.

- ↑ "Tensile and creep properties of ultra high molecular weight PE fibres" (PDF). Archived from the original (PDF) on 28 June 2007. Retrieved 11 May 2007.

- ↑ "Mechanical Properties Data". www.mse.mtu.edu. Archived from the original on 3 May 2007.

- ↑ "MatWeb – The Online Materials Information Resource". Archived from the original on 21 February 2015. Retrieved 20 February 2015.

- ↑ "Nylon Fibers". University of Tennessee. Archived from the original on 19 April 2015. Retrieved 25 April 2015.

- ↑ "Comparing aramids". Teijin Aramid. Archived from the original on 3 May 2015.

- ↑ "Uhu endfest 300 epoxy: Strength over setting temperature". Archived from the original on 19 July 2011.

- ↑ "Fols.org" (PDF). Archived (PDF) from the original on 25 July 2011.

- ↑ "What is the density of Hydrogenated Boron Nitride Nanotubes (H-BNNT)?". space.stackexchange.com. Archived from the original on 13 April 2017.

- ↑ Lee, C.; et al. (2008). "Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene". Science. 321 (5887): 385–8. Bibcode:2008Sci...321..385L. doi:10.1126/science.1157996. PMID 18635798. Archived from the original on 19 February 2009. Lay summary.

- ↑ IOP.org Z. Wang, P. Ciselli and T. Peijs, Nanotechnology 18, 455709, 2007.

- ↑ Xu, Wei; Chen, Yun; Zhan, Hang; Nong Wang, Jian (2016). "High-Strength Carbon Nanotube Film from Improving Alignment and Densification". Nano Letters. 16: 946–952. Bibcode:2016NanoL..16..946X. doi:10.1021/acs.nanolett.5b03863.

- ↑ Barber, A. H.; Lu, D.; Pugno, N. M. (2015). "Extreme strength observed in limpet teeth". Journal of the Royal Society Interface. 12: 105. doi:10.1098/rsif.2014.1326.

- ↑ Yu, Min-Feng; Lourie, O; Dyer, MJ; Moloni, K; Kelly, TF; Ruoff, RS (2000). "Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load". Science. 287 (5453): 637–640. Bibcode:2000Sci...287..637Y. doi:10.1126/science.287.5453.637. PMID 10649994.

- ↑ Li, F.; Cheng, H. M.; Bai, S.; Su, G.; Dresselhaus, M. S. (2000). "Tensile strength of single-walled carbon nanotubes directly measured from their macroscopic ropes". Applied Physics Letters. 77: 3161. Bibcode:2000ApPhL..77.3161L. doi:10.1063/1.1324984. Archived from the original on 2016-05-14.

- ↑ K.Hata. "From Highly Efficient Impurity-Free CNT Synthesis to DWNT forests, CNTsolids and Super-Capacitors" (PDF). Archived (PDF) from the original on 12 June 2010.

- ↑ Elices; et al. "Finding Inspiration in Argiope Trifasciata Spider Silk Fibers". JOM. Archived from the original on 15 January 2009. Retrieved 23 January 2009.

- ↑ Blackledge; et al. "Quasistatic and continuous dynamic characterization of the mechanical properties of silk from the cobweb of the black widow spider Latrodectus hesperus". The Company of Biologists. Archived from the original on 1 February 2009. Retrieved 23 January 2009.

- ↑ A.M. Howatson, P. G. Lund, and J. D. Todd, Engineering Tables and Data, p. 41

Further reading

- Giancoli, Douglas, Physics for Scientists & Engineers Third Edition (2000). Upper Saddle River: Prentice Hall.

- Köhler T, Vollrath F (1995). "Thread biomechanics in the two orb-weaving spiders Araneus diadematus (Araneae, Araneidae) and Uloboris walckenaerius (Araneae, Uloboridae)". Journal of Experimental Zoology. 271: 1–17. doi:10.1002/jez.1402710102.

- T Follett, Life without metals

- Min-Feng Y, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS (2000). "Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load". Science. 287 (5453): 637–640. Bibcode:2000Sci...287..637Y. doi:10.1126/science.287.5453.637. PMID 10649994.

- George E. Dieter, Mechanical Metallurgy (1988). McGraw-Hill, UK