Superconducting wire

Superconducting wire is wire made of superconductors. When cooled below its transition temperature, it has zero electrical resistance. Most commonly, conventional superconductors such as niobium-titanium are used,[1] but high-temperature superconductors such as YBCO are entering the market. Superconducting wire's advantages over copper or aluminum include higher maximum current densities and zero power dissipation. Its disadvantages include the cost of refrigeration of the wires to superconducting temperatures (often requiring cryogens such as liquid helium or liquid nitrogen), the danger of the wire quenching (a sudden loss of superconductivity), the inferior mechanical properties of some superconductors, and the cost of wire materials and construction.[2] Its main application is in superconducting magnets, which are used in scientific and medical equipment where high magnetic fields are necessary.

Important parameters of SC wires/tapes/conductors

The construction and operating temperature will typically be chosen to maximise:

- critical temperature Tc, below this temperature the wire becomes a superconductor

- critical current density Jc, maximum super-current a superconducting wire can carry per unit cross sectional area (see images below for examples with 20 kA/cm2).

Two key features of these practical Superconductors (wires/tapes/cables) are superconducting compound in form of filaments/coating and an electrically conducting stabilizer (usually Copper). The function of stabilizer is to carry current in case of loss of superconductivity (so called quench) in these superconductors [3][4]. Current sharing temperature Tcs is the temperature at which the current transported through the superconductor strands starts to flow through the stabilizer[5][6]. However, Tcs is not the same as the quench temperature (or critical Temperature) Tc. In the former case there is partial loss of superconductivity, while in the latter case the superconductivity is totally lost[7]

LTS wire

Low-temperature superconductor (LTS) wires are made from superconductors with low critical temperature, such as Nb3Sn(niobium-tin) and NbTi(niobium-titanium). Often the superconductor is in filament form in a copper or aluminium matrix which carries the current should the superconductor quench for any reason. The superconductor filaments can form a third of the total volume of the wire.

Preparation

Wire drawing

The normal wire drawing process can be used for malleable alloys such as niobium-titanium.

Surface diffusion

Vanadium-gallium (V3Ga) can be prepared by surface diffusion where the high temperature component as a solid is bathed in the other element as liquid or gas.[8] When all components remain in the solid state during high temperature diffusion this is known as the bronze process.[9]

Cross sections of various (Nb,Ti)3Sn composite superconducting cables and wires. (440 to 7,800 A in 8 to 19 Tesla fields).

Cross sections of various (Nb,Ti)3Sn composite superconducting cables and wires. (440 to 7,800 A in 8 to 19 Tesla fields). V3Ga superconducting tape (10×0.14 mm cross section). A vanadium core is covered with 15 µm V3Ga layer, then 20 µm bronze (stabilizing layer) and 15 µm insulating layer. Critical current 180 A (19.2 tesla, 4.2 K), critical current density 20 kA/cm2

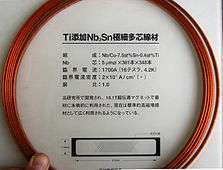

V3Ga superconducting tape (10×0.14 mm cross section). A vanadium core is covered with 15 µm V3Ga layer, then 20 µm bronze (stabilizing layer) and 15 µm insulating layer. Critical current 180 A (19.2 tesla, 4.2 K), critical current density 20 kA/cm2 Nb/Cu-7.5at%Sn-0.4at%Ti tape (9.5×1.8 mm cross section) originally developed for an 18.1 T magnet. Nb core: 361×348 packs of 5 µm dia. filaments. Critical current 1700 A (16 tesla, 4.2 K), critical current density 20 kA/cm2

Nb/Cu-7.5at%Sn-0.4at%Ti tape (9.5×1.8 mm cross section) originally developed for an 18.1 T magnet. Nb core: 361×348 packs of 5 µm dia. filaments. Critical current 1700 A (16 tesla, 4.2 K), critical current density 20 kA/cm2

HTS wire

High-temperature superconductor (HTS) wires are made from superconductors with high critical temperature(high-temperature superconductivity), such as YBCO and BSCCO.

Powder-in-tube

The powder-in-tube (PIT, or oxide powder in tube, OPIT) process is often used for making electrical conductors from brittle superconducting materials such as niobium-tin[10] or magnesium diboride,[11] and ceramic cuprate superconductors such as BSCCO.[12][13] It has been used to form wires of the iron pnictides.[14] (PIT is not used for yttrium barium copper oxide as it does not have the weak layers required to generate adequate 'texture' (alignment) in the PIT process.)

This process is used because the high-temperature superconductors are too brittle for normal wire forming processes. The tubes are metal, often silver. Often the tubes are heated to react the mix of powders. Once reacted the tubes are sometimes flattened to form a tape-like conductor. The resulting wire is not as flexible as conventional metal wire, but is sufficient for many applications.

There are in situ and ex situ variants of the process, as well a 'double core' method that combines both.[15]

Coated superconductor tape or wire

The coated superconductor tapes are known as second generation superconductor wires. These wires are in a form of a metal tape of about 10 mm width and about 100 micrometer thickness, coated with superconductor materials such as YBCO. A few years after the discovery of High-temperature superconductivity materials such as the YBCO, it was demonstrated that epitaxial YBCO thin films grown on lattice matched single crystals such as magnesium oxide MgO, strontium titanate (SrTiO3) and sapphire had high supercritical current densities of 1–4 MA/cm2.[16][17] However, a lattice-matched flexible material was needed for producing a long tape. YBCO films deposited directly on metal substrate materials exhibit poor superconducting properties. It was demonstrated that a c-axis oriented yttria-stabilized zirconia (YSZ) intermediate layer on a metal substrate can yield YBCO films of higher quality, which had still one to two orders less critical current density than that produced on the single crystal substrates.[18][19]

The breakthrough came with the invention of ion beam-assisted deposition (IBAD) technique to produce of biaxially aligned yttria-stabilized zirconia (YSZ) thin films on metal tapes.[20]

The biaxial YSZ film acted as a lattice matched buffer layer for the epitaxial growth of the YBCO films on it. These YBCO films achieved critical current density of more than 1 MA/cm2. Other buffer layers such as cerium oxide (CeO2 and magnesium oxide (MgO) were produced using the IBAD technique for the superconductor films.[21][22][23]

Smooth substrates with roughness in the order of 1 nm are essential for the high quality superconductor films. Initially hastelloy substrates were electro polished to create a smoothed surface. Hastelloy is a nickel based alloy capable of withstanding temperatures up to 800C without melting or heavily oxidizing. Currently a coating technique known as “spin on glass” or “solution deposition planarization” is used to smooth the substrate surface.[24][25]

Recently YBCO coated superconductor tapes capable of carrying more than 500 A/cm-width at 77 K and 1000 A/cm-width at 30 K under high magnetic field have been demonstrated.[26][27][28][29]

Chemical vapor deposition

CVD is used for YBCO coated tapes.

Hybrid physical-chemical vapor deposition

HPCVD can be used for thin-film magnesium diboride. (Bulk MgB2 can be made by PIT or reactive Mg liquid infiltration.)

Reactive co-evaporation

Superconducting layer in the 2nd generation superconducting wires can be grown by reactive co-evaporation of constituent metals, rare-earth element, barium, and copper.

Standards

There are several IEC (International Electrotechnical Commission) standards related to superconducting wires under TC90.

See also

- Niobium-titanium – easier to handle

- Niobium-tin – difficult to handle, higher critical field

- YBCO

- BSCCO

- High-temperature superconductivity

- Residual-resistivity ratio

References

- ↑ "Characteristics of Superconducting Magnets". Superconductivity Basics. American Magnetics Inc. 2008. Retrieved 2008-10-11.

- ↑ "Superconducting wire breaks record". Physics World. Retrieved 2009-09-03.

- ↑ Wilson, Martin N. "Superconducting magnets." (1983).

- ↑ https://indico.cern.ch/event/440690/contributions/1089752/attachments/1143848/1639300/U4_final.pdf

- ↑ Bottura, L. "Magnet quench 101." arXiv preprint arXiv:1401.3927 (2014).

- ↑ https://repositorio.unican.es/xmlui/handle/10902/12040

- ↑ Ekin, Jack. Experimental techniques for low-temperature measurements: cryostat design, material properties and superconductor critical-current testing. Oxford university press, 2006.

- ↑ Matsushita, Teruo; Kikitsu, Akira; Sakata, Haruhisa; Yamafuji, Kaoru; Nagata, Masayuki (1986). "Elementary Pinning Force of Grain Boundaries in Superconducting V3Ga Tapes". Japanese Journal of Applied Physics. 25: L792. Bibcode:1986JaJAP..25L.792M. doi:10.1143/JJAP.25.L792.

- ↑ Dew-Hughes, D. (1978). "Solid-state (bronze process) V3Ga from a V-Al alloy core". Journal of Applied Physics. 49: 327. Bibcode:1978JAP....49..327D. doi:10.1063/1.324390.

- ↑ Lindenhovius, J.L.H.; Hornsveld, E.M.; Den Ouden, A.; Wessel, W.A.J.; Ten Kate, H.H.J. (2000). "Powder-in-tube (PIT) Nb/sub 3/Sn conductors for high-field magnets". IEEE Transactions on Applied Superconductivity. 10: 975. Bibcode:2000ITAS...10..975L. doi:10.1109/77.828394.

- ↑ Glowacki, B.A; Majoros, M; Vickers, M.E; Zeimetz, B (2001). "Superconducting properties of the powder-in-tube Cu-Mg-B and Ag-Mg-B wires". Physica C: Superconductivity. 372–376: 1254. arXiv:cond-mat/0109085. Bibcode:2002PhyC..372.1254G. doi:10.1016/S0921-4534(02)00986-3.

- ↑ Larbalestier, David et al. (1997) Ch. 5 "Sheathed or Powder-in-Tube Conductors" in WTEC Panel Report on Power Applications of Superconductivity in Japan and Germany

- ↑ Beales, Timothy P.; Jutson, Jo; Le Lay, Luc; Mölgg, Michelé (1997). "Comparison of the powder-in-tube processing properties of two (Bi2−xPbx)Sr2Ca2Cu 3O10+δ powders". Journal of Materials Chemistry. 7 (4): 653. doi:10.1039/a606896k.

- ↑ Ma, Y.; et al. (2009). "Fabrication and characterization of iron pnictide wires and bulk materials through the powder-in-tube method". Physica C. 469 (9–12): 651–656. arXiv:0906.3114. Bibcode:2009PhyC..469..651M. doi:10.1016/j.physc.2009.03.024.

- ↑ Nakane, T.; Takahashi, K.; Kitaguchi, H.; Kumakura, H. (2009). "Fabrication of Cu-sheathed MgB2 wire with high Jc–B performance using a mixture of in situ and ex situ PIT techniques". Physica C: Superconductivity. 469 (15–20): 1531–1535. Bibcode:2009PhyC..469.1531N. doi:10.1016/j.physc.2009.05.227.

- ↑ Blue, C., & Boolchand, P. (1991). "In situ preparation of superconducting Y1Ba2Cu3O7−δ thin films by on‐axis rf magnetron sputtering from a stoichiometric target". Applied Physics Letters. 58 (18): 2036. Bibcode:1991ApPhL..58.2036B. doi:10.1063/1.105005.

- ↑ Savvides, N., & Katsaros, A. (1993). "In situ growth of epitaxial YBa2Cu3O7 thin films by on‐axis unbalanced direct current magnetron sputtering". Applied Physics Letters. 62 (5): 528. Bibcode:1993ApPhL..62..528S. doi:10.1063/1.108901.

- ↑ Russo, R. E., Reade, R. P., McMillan, J. M., & Olsen, B. L. (1990). "Metal buffer layers and Y‐Ba‐Cu‐O thin films on Pt and stainless steel using pulsed laser deposition". Journal of Applied Physics. 68 (3): 1354. Bibcode:1990JAP....68.1354R. doi:10.1063/1.346681.

- ↑ Reade, R. P., Berdahl, P., Russo, R. E., & Garrison, S. M. Laser (1992). "deposition of biaxially textured yttria‐stabilized zirconia buffer layers on polycrystalline metallic alloys for high critical current Y‐Ba‐Cu‐O thin films". Applied Physics Letters. 61 (18): 2231. Bibcode:1992ApPhL..61.2231R. doi:10.1063/1.108277.

- ↑ Iijima, Y.; Tanabe, N.; Kohno, O.; Ikeno, Y. (1992). "In-plane aligned YBa2Cu3O7−x thin films deposited on polycrystalline metallic substrates". Applied Physics Letters. 60 (6): 769. Bibcode:1992ApPhL..60..769I. doi:10.1063/1.106514.

- ↑ Gnanarajan, S., Katsaros, A., & Savvides, N. (1997). "Biaxially aligned buffer layers of cerium oxide, yttria stabilized zirconia, and their bilayers". Applied Physics Letters. 70 (21): 2816. Bibcode:1997ApPhL..70.2816G. doi:10.1063/1.119017.

- ↑ Wang, C. P., Do, K. B., Beasley, M. R., Geballe, T. H., & Hammond, R. H (1997). "Deposition of in-plane textured MgO on amorphous Si3N4 substrates by ion-beam-assisted deposition and comparisons with ion-beam-assisted deposited yttria-stabilized-zirconia". Applied Physics Letters. 71 (20): 2955. Bibcode:1997ApPhL..71.2955W. doi:10.1063/1.120227.

- ↑ Arendt, P.N.; Foltyn, S.R.; Civale, L.; Depaula, R.F.; Dowden, P.C.; Groves, J.R.; Holesinger, T.G.; Jia, Q.X.; Kreiskott, S.; Stan, L.; Usov, I.; Wang, H.; Coulter, J.Y. (2004). "High critical current YBCO coated conductors based on IBAD MgO". Physica C. 412: 795. Bibcode:2004PhyC..412..795A. doi:10.1016/j.physc.2003.12.074.

- ↑ Gnanarajan, S., & Du, J. (2005). "Flexible YBa2Cu3O7−δ-coated superconductor tapes on non-metallic substrates with spin-on-glass and IBAD-YSZ buffer layers". Superconductor Science and Technolog. 18 (4): 381. Bibcode:2005SuScT..18..381G. doi:10.1088/0953-2048/18/4/001.

- ↑ Sheehan, Chris; Jung, Yehyun; Holesinger, Terry; Feldmann, D. Matthew; Edney, Cynthia; Ihlefeld, Jon F.; Clem, Paul G.; Matias, Vladimir (2011). "Solution deposition planarization of long-length flexible substrates". Applied Physics Letters. 98 (7): 071907. Bibcode:2011ApPhL..98g1907S. doi:10.1063/1.3554754.

- ↑ Foltyn, S.R.; Arendt, P.N.; Dowden, P.C.; Depaula, R.F.; Groves, J.R.; Coulter, J.Y.; Quanxi Jia; Maley, M.P.; Peterson, D.E. (1999). "High-Tc coated conductors-performance of meter-long YBCO/IBAD flexible tapes". IEEE Transactions on Appiled Superconductivity. 9 (2): 1519. Bibcode:1999ITAS....9.1519F. doi:10.1109/77.784682.

- ↑ Usoskin, A., & Freyhardt, H. C. (2011). "YBCO-Coated Conductors Manufactured by High-Rate Pulsed Laser Deposition". MRS Bulletin. 29 (8): 583. doi:10.1557/mrs2004.165.

- ↑ Pahlke, Patrick; Hering, Michael; Sieger, Max; Lao, Mayraluna; Eisterer, Michael; Usoskin, Alexander; Stromer, Jan; Holzapfel, Bernhard; Schultz, Ludwig; Huhne, Ruben (2015). "Thick High Jc YBCO Films on ABAD-YSZ Templates". IEEE Transactions on Applied Superconductivity. 25 (3): 1. Bibcode:2015ITAS...2578533P. doi:10.1109/TASC.2014.2378533.

- ↑ Selvamanickam, V., Gharahcheshmeh, M. H., Xu, A., Zhang, Y., & Galstyan, E. (2015). "Critical current density above 15 MA cm−2 at 30 K, 3 T in 2.2 μm thick heavily-doped (Gd,Y)Ba2Cu3Ox superconductor tapes". Superconductor Science and Technology. 28 (7): 072002. Bibcode:2015SuScT..28g2002S. doi:10.1088/0953-2048/28/7/072002.