Prusa i3

Prusa i3 MK2 | |

|

A Prusa i3 MK2 print farm producing parts for new printers | |

| Classification | Fused deposition modeling 3D printer |

|---|---|

| Inventor | Josef Průša |

The Prusa i3 is an open-source fused deposition modeling 3D printer. Part of the RepRap project, it is the most used 3D printer in the world.[1][2] The Prusa i3 was designed by Josef Průša in 2012 with the Prusa i3 MK2 being released in 2016 and the MK2S being released in 2017.[3] The latest version, called the Prusa i3 MK3 was released in September 2017 with significant improvements over the prior models. The Prusa i3's comparable low cost and ease of construction and modification has made it popular in education and with hobbyists and professionals.[4][5] Due to the printer being open source there have been many variants produced by companies and individuals worldwide, and like many other RepRap printers the Prusa i3 is capable of printing some of its own parts.[6]

History

The Prusa i3 is the third printer design by Josef Průša, a core developer of the RepRap project who had previously developed the PCB heated bed.[7] The first iteration was the Prusa Mendel[8] produced in 2010 followed by the Prusa Mendel (iteration 2), in 2011.[9] The printer was named Prusa Mendel by the RepRap community rather than Průša himself.[5]

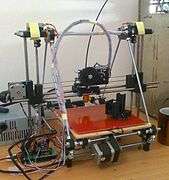

Prusa Mendel

Prusa Mendel.jpg) Prusa Mendel (iteration 2)

Prusa Mendel (iteration 2) Prusa i3

Prusa i3 Prusa i3 MK2

Prusa i3 MK2

Prusa Mendel

The first Prusa Mendel was released in September 2010 with the aim of simplifying the existing Mendel design, including reducing the time needed to create the 3D printed parts from 20 to 10 hours and 3D printable bushings replacing regular bearings.[5][8]

Prusa Mendel (iteration 2)

The second Prusa Mendel was released in November 2011 and with upgrades including snap fit parts, reduction of the number of tools needed to construct, maintain the printer and improved belts attached to the stepper motors and use of LM8UU linear bearings.[9]

Prusa i3

In May 2012[10] designs (produced in OpenSCAD) for the Prusa i3 were released, it was a major redesign from previous versions and other RepRap printers. The design replaced the triangular threaded rod frame construction with a water jet cut aluminum frame, had a food-safe hot end called the Prusa Nozzle, and used M5 threaded screws instead of M8.[11][12][13][14] The design focused on ease of construction and use rather than maximising the number of self replicated components.[15] In 2015 Průša released a version which he called the Original Prusa i3, selling through his company Prusa Research.[1]

Prusa i3 MK2

In May 2016 the Prusa i3 MK2 was released, it is the first printer with automatic geometry skew correction for all three axes and includes a larger build volume, custom stepper motors with integrated lead screws, mesh bed levelling using a non-contact inductance sensor and a rewritten version of the Marlin firmware.[3][16][17][18] Other new features include a polyetherimide print surface, Rambo controller board and an E3D V6 Full hotend.[19][20] The Prusa MK2 became the first RepRap printer to be supported by Windows Plug-and-Play USB ID.[21]

Prusa i3 MK2S

In March 2017, Josef Prusa announced on his blog [22] that the Prusa i3 MK2 was now shipping as the Prusa i3 MK2S. Enhancements cited include U-bolts to hold the LM8UU bearings, improved LM8UU bearings, smoother rods, an improved mount for the inductance sensor, improved cable management, and a new electronics cover. While new shipments of the MK2 automatically receive the "S" upgrades, an upgrade kit is available to bring these improvements to earlier purchasers.

Prusa i3 MK3 and MK2.5

In September 2017, Prusa i3 MK3 was released,[23] marketed as "bloody smart". Upgraded features included:[24] a sturdier Y axis, a new extruder with double sided Bondtech drive-gears, quieter fans with rpm monitoring, an updated bed leveling sensor, a new electronics board named "Einsy", quieter stepper motors with 128 step microstepping drivers and a magnetic heatbed with interchangeable PEI-coated steel sheets. This model also includes new sensors: several temperature sensors, a filament detector, and a sensor that detects power interruptions. The MK3 runs on 24V instead of 12V, so all the electrical components were updated to 24V variants. The printer also offers dedicated sockets to connect Raspberry Pi Zero W running open source Octoprint software for wireless printing, and offers a custom Octoprint build for Prusa i3.

The idea of the MK3 update was to make the printer easier to use for casual users and less likely to lead to failed prints. The filament detector allows users to load filament just by inserting it, and it can detect and pause the print if the filament is jammed or runs out. In both cases, printing resumes normally after the issue is fixed. The new stepper motor drivers can handle skipped steps automatically and prevent layer shifts. The power panic sensor allows the printer to recover from power outages, and uses the remaining charge in the power supply's capacitors to lift the print head up to prevent it from melting the printed part while the power is out. The ambient temperature sensor is able to detect mainboard overheating caused by loose electrical connections.

The upgraded chassis and electronics also allow for faster print speeds — up to 200 mm/s.

Existing MK2 and MK2S users were offered a $200 partial upgrade named MK2.5, limited to features which are cheaper to upgrade. After negative feedback from the community, Prusa made available a more expensive $500 MK2S to MK3 full upgrade.

Clones

As an open-source design the success of the Prusa i3 is underlined by the ready availability of both complete and kit-built machines that follow the various iterations of the i3 design. Rather than compete directly with these versions, Prusa Research's strategy is to pursue continual refinement of its designs.[25]

Recognition

In 2012 Josef received honours from the governor of the Vysočina Region in the Czech Republic for his accomplishments in technology.[26] In February 2014 he was featured on the cover of Czech Forbes magazine as one of the 30 under 30 list.[27]

Capabilities

Self replication

Like other RepRap printers the Prusa i3 is capable of creating many of its own parts, which were usually printed in ABS plastic prior to the Mk3, which uses PETG instead.[28] The standard Prusa i3 has 26 printed parts.

Printable materials

Depending on the hot end and heated bed installed, the Prusa i3 is capable of printing many materials including Acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), high impact polystyrene (HIPS), polyetilene (PET), different flexible filaments (FLEX, TPU, TPE), polypropylene (PP) and nylon.[29] Different materials require different working temperatures and techniques to make them adhere to the print bed.

Components

The Prusa i3, like many RepRap printers, is made from a combination of self-replicated 3D printed parts and off-the-shelf components which are commonly referred to as "vitamins", as they cannot be produced by the printer itself.[30]

The vitamins used on the Prusa i3 are a combination of common components including threaded rods, smooth rods, screws, nuts, 5 NEMA 17 stepper motors and more specialist equipment including a controller board, heated bed and hot end.

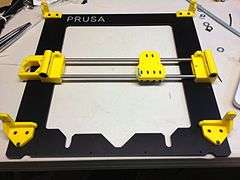

Metal frame and constructed Y axis, printed parts in yellow.

Metal frame and constructed Y axis, printed parts in yellow. Assembled Y axis, printed parts in yellow.

Assembled Y axis, printed parts in yellow. Prusa i3 extruder and hot end with yellow printed parts.

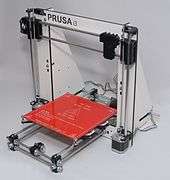

Prusa i3 extruder and hot end with yellow printed parts. Completed Prusa i3, printed parts in yellow.

Completed Prusa i3, printed parts in yellow.

Variants

Due to its popularity the Prusa i3 has many variants produced by different companies and individuals around the world including different styles of frame and extruders.[31]

Frames

The main variant in designs of the Prusa i3 are different frames used, these include a single sheet frame cut from steel, acrylic (laser cut or CNC milled), medium-density fibreboard box frames and Lego.[32][33][34][35]

A Prusa i3 with a standard metal frame.

A Prusa i3 with a standard metal frame. A Prusa Xi3 with an acrylic frame.

A Prusa Xi3 with an acrylic frame. A Prusa i3 with a plywood box frame.

A Prusa i3 with a plywood box frame. A Prusa i3 with a melamine-resin particle board frame.

A Prusa i3 with a melamine-resin particle board frame.

Extruders

A partially printed single-colour object showing the infill created to reduce the amount of plastic used.

A partially printed single-colour object showing the infill created to reduce the amount of plastic used. A 3DBenchy created on a Prusa i3 using a color-mixing hot end.

A 3DBenchy created on a Prusa i3 using a color-mixing hot end.

There are a range of different extruders used on variants of the Prusa i3 including 1.75 mm and 3 mm filament extruders and other tool heads including a MIG welder and a laser cutter.[36][37][38]

References

- 1 2 "What's up with Original Prusa i3? – Prusa Printers". Prusa Printers. 2016-03-02. Retrieved 2016-06-13.

- ↑ "3D Printing Trends June 2016". 3D Hubs. Retrieved 2016-06-29.

- 1 2 By. "Prusa Shows Us the New i3 MK2 3D Printer and Where the Community is Headed". Hackaday. Retrieved 2016-06-15.

- ↑ Ertischek, David (2016-02-03). "Prusa I3 is a DIY 3D printer you can actually afford". BGR. Retrieved 2016-06-12.

- 1 2 3 "The Story of RepRap Prusa Mendel – MakingSociety". MakingSociety. 2014-01-15. Retrieved 2016-06-16.

- ↑ 3D Hubs

- ↑ Thingiverse.com. "PCB heated print bed by josefprusa". www.thingiverse.com. Retrieved 2016-06-19.

- 1 2 "first commit · josefprusa/PrusaMendel@6ed4480". GitHub. Retrieved 2016-06-13.

- 1 2 "Hobbyist Weekend – With Prusa Mendel 3D Printer". 3D Printing Industry. Retrieved 2016-06-15.

- ↑ "initial commit · josefprusa/Prusa3@d3618a6". GitHub. Retrieved 2016-06-13.

- ↑ By. "ImplicitCAD: Programmatic CAD Built with 3D Printing in Mind". Hackaday. Retrieved 2016-06-15.

- ↑ By. "Interview With A Printer". Hackaday. Retrieved 2016-06-17.

- ↑ "Prusa Nozzle: All metal food safe RepRap hot-end". 3ders.org. Retrieved 2016-06-19.

- ↑ By. "Fail Of The Week: My 3D Printer Upgrade". Hackaday. Retrieved 2016-06-15.

- ↑ "Open Source 3D printing: an Interview with Josef Prusa". Open Electronics. Retrieved 2016-06-16.

- ↑ "Josef Prusa unveils $699 Original Prusa i3 MK2 3D printer". 3ders.org. Retrieved 2016-06-13.

- ↑ "Josef Prusa unveils $699 Original Prusa i3 MK2 3D printer". 3ders.org. Retrieved 2016-06-19.

- ↑ "The first printer to correct its geometry in all axes - Prusa Printers". 2016-08-11. Retrieved 2016-08-13.

- ↑ "The All New Original Prusa i3 MK2 Kit Has a Ton of New Features". 3DPrint.com. 2016-05-18. Retrieved 2016-06-19.

- ↑ "Interview with Josef Prusa, CEO and Founder of Prusa Research". 3D Printing Industry. Retrieved 2016-06-12.

- ↑ "Microsoft adds network 3D printing support with Windows 10 IoT Core app for Raspberry Pi 3". 3ders.org. Retrieved 2016-06-12.

- ↑ "Original Prusa I3 MK2S Release". Official Prusa 3D printers community. Retrieved 2017-04-13.

- ↑ "Original Prusa i3 MK3 is out! And it's bloody smart! - Prusa Printers". Prusa Printers. 22 September 2017. Retrieved 24 October 2017.

- ↑ "New Original Prusa i3 MK3: Review the Facts Here! | All3DP". All3DP. 25 September 2017. Retrieved 24 October 2017.

- ↑

- ↑ "Jihlavské listy | Aktuality | Noviny Kraje Vysočina". www.jihlavske-listy.cz. Retrieved 2016-06-13.

- ↑ "Forbes Česko". www.facebook.com. Retrieved 2016-06-13.

- ↑ "Original Prusa i3 Mk3 after 2 months". prusaprinters.org. Retrieved 2018-03-14.

- ↑ "Material guides – Prusa3D – 3D Printers from Josef Průša". Prusa3D – 3D Printers from Josef Průša. Retrieved 2016-06-19.

- ↑ "Distributing 3DP Parts — and Vitamins — With Passion". 3D Printing Industry. Retrieved 2016-06-15.

- ↑ By. "[Prusa] interviews a whole bunch of RepRappers". Hackaday. Retrieved 2016-06-17.

- ↑ "Portugal's Reprapalgarve Team Shows Us How to Make a Steel Framed Color 3D Printer for Around $600". 3DPrint.com. 2016-06-06. Retrieved 2016-06-15.

- ↑ "RepRap iTopie Emerges as Improvement on Prusa i3". 3DPrint.com. 2014-12-18. Retrieved 2016-06-15.

- ↑ By. "Lego Printer Prints Lego". Hackaday. Retrieved 2016-06-19.

- ↑ "Build your very own Prusa l3 LEGO 3D printer using (almost) nothing but LEGO bricks". 3ders.org. Retrieved 2016-06-19.

- ↑ "Dutch students build DIY metal 3D printer using Prusa i3 printer and a MIG welder". 3ders.org. Retrieved 2016-06-19.

- ↑ "Students Combine Prusa i3 Printer with a MIG Welder to Create an Affordable Metal 3D Printer". 3DPrint.com. 2014-11-17. Retrieved 2016-06-19.

- ↑ "DIY 3D Printing: Laser cutting with Prusa Mendel i2". diy3dprinting.blogspot.co.uk. Retrieved 2016-06-19.