Small modular reactor

Small modular reactors (SMRs) are a type of nuclear fission reactor which are smaller than conventional reactors, and manufactured at a plant and brought to a site to be fully constructed. Modular reactors allow for less on-site construction, increased containment efficiency, and heightened nuclear materials security. SMRs have been proposed as a less expensive alternative to conventional nuclear reactors.

Several designs exist for SMR, ranging from scaled down versions of existing nuclear reactor designs, to entirely new generation IV designs. Both thermal-neutron reactors and fast-neutron reactors have been proposed.

Advantages and potential uses

The main advantage of small modular reactors is that they could be manufactured and assembled at a central factory location. They can then be sent to their new location where they can be installed with very little difficulty. SMRs are particularly useful in remote locations where there is usually a deficiency of trained workers and a higher cost of shipping. Containment is more efficient, and proliferation concerns could be lowered.[1] SMRs are also more flexible in that they do not necessarily need to be hooked into a large power grid, and can generally be attached to other modules to provide increased power supplies if necessary.

The electricity needs in remote locations are usually small and highly variable.[2] Large nuclear power plants are generally rather inflexible in their power generation capabilities. SMRs have a load-following design so that when electricity demands are low they will produce a lower amount of electricity.

Many SMRs are designed to use new fuel ideas that allow for higher burnup and longer fuel cycles. Longer refueling intervals can decrease proliferation risks and lower chances of radiation escaping containment. For reactors in remote areas, accessibility can be troublesome, so longer fuel life can be very helpful.

SMRs could be used to power significant users of energy, such as large vessels or production facilities (e.g. water treatment/purification, or mines). Remote locations often have difficulty finding economically efficient, reliable energy sources. Small nuclear reactors have been considered as solutions to many energy problems in these hard-to-reach places. Cogeneration options are also possible.[3]

Because of the lack of trained personnel available in remote areas, SMRs have to be inherently safe. Many larger plants have active safety features that require "intelligent input", or human controls. Many of these SMRs are being made using passive or inherent safety features. Passive safety features are engineered, but do not require outside input to work. A pressure release valve may have a spring that can be pushed back when the pressure gets too high. Inherent safety features require no engineered moving parts to work. They only depend on physical laws.[4]

Operation

There are a variety of different types of SMR. Some are simplified versions of current reactors, others involve entirely new technologies.[5]

All current small modular reactors use nuclear fission.

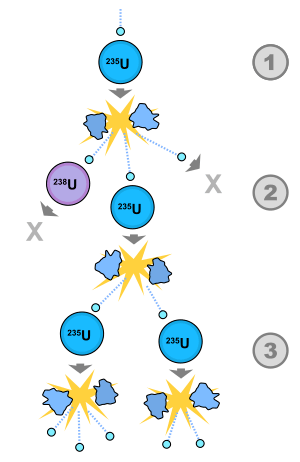

When an unstable nucleus (such as 235

U) absorbs an extra neutron, the atom will split, releasing large quantities of energy in the form of heat and radiation.

The split atom will also release neutrons, which can then be absorbed by other unstable nuclei, causing a chain reaction. A sustained fission chain is necessary to generate nuclear power.

SMR designs include thermal-neutron reactors and fast-neutron reactors.

Thermal-neutron reactors rely on a moderator to slow neutrons and generally use 235

U as fissile material. Most currently operating nuclear reactors are of this type.

Fast reactors don’t use moderators to slow down the neutrons, therefore they rely on the nuclear fuel being able to absorb neutrons travelling at higher speeds.

This usually means changing the fuel arrangement within the core, or using different fuel types. 239

Pu is more likely to absorb a high-speed neutron than 235

U.

A benefit of fast reactors is that they can be designed to be breeder reactors.

As these reactors produce energy, they also let off enough neutrons to transmute non-fissionable elements into fissionable ones.

A very common use for a breeder reactor is to surround the core in a "blanket" of 238

U, which is the most easily found isotope of uranium.

Once the 238

U undergoes a neutron absorption reaction, it becomes 239

Pu, which can be removed from the reactor once it is time to refuel, and used as more fuel once it has been cleaned.[6]

Cooling

Currently, most reactors use water as a coolant. New reactor designs are experimenting with different coolant types. Liquid metal cooled reactors have been used both in the United States and other countries for some time. Gas cooled reactors and molten salt reactors are also being looked at as an option for very high temperature operation.[7][8]

Thermal/electrical generation

Traditionally, nuclear reactors use a coolant loop to heat water into steam, and use that steam to run turbines to generate electricity. Some new gas-cooled reactor designs are meant to drive a gas-powered turbine, rather than using a secondary water system. Thermal energy from nuclear reactors can also be used directly, without conversion to electricity. Nuclear reactor heat can be used in hydrogen production and other commercial operations,[7] such as water desalination, production of petroleum products (extracting oil from tar sands, creating synthetic oil from coal, etc.), and the production of hydrogen.[9]

Staffing

Several SMR developers are claiming that their designs will require fewer staff members to run the reactors because of the increased inherent and passive safety systems. Some of the reactors, like the Toshiba 4S, are reportedly designed to run with little supervision.[10]

Load following

Nuclear power plants have been historically deployed to cover the base load of the electricity demand.[11] Some nuclear power plants might perform daily load cycling operation (i.e. load following) between 50% and 100% of their rated power. With respect to the insertion of control rods or comparable action to reduce the nuclear power generation, a more efficient alternative might be the “Load Following by Cogeneration”, i.e. diverting the excess of power, respect to the electricity demand, to an auxiliary system. A suitable cogeneration system needs:

- to have a demand of electricity and/or heat in the region of 500 MWe–1.5 GWt;

- to meet a significant market demand;

- to have access to adequate input to process;

- to be flexible: cogeneration might operate at full load during the night when the request of electricity is low, and be turned off during the daytime.

From the economic standpoint, it is essential that the investment in the auxiliary system is profitable. District heating, desalination and hydrogen have been proposed as technically and economically feasible options.[12] SMR can be ideal to do load following being used for desalination over the night. [13]

Waste reduction

Many SMRs are fast reactors that are designed to have higher fuel burnup rates, reducing the amount of waste produced. At higher neutron energy more fission products can be usually tolerated. As mentioned before, some SMRs are also breeder reactors, which not only "burn" fuels like 235

U, but will also convert fissionable materials like 238

U (which occurs naturally at a much higher concentration than 235

U) into usable fuels.[6]

Some reactors are designed to run on alternative thorium fuel cycle, which offers significantly reduced long-term waste radiotoxicity compared to uranium cycle.[14]

There has been some interest in the concept of a traveling wave reactor, a new type of breeder reactor that uses the fuel it breeds. The idea would eliminate the need to remove the spent fuel and "clean" it before reusing any newly bred fuel.[15]

Safety

Since there are several different ideas for SMRs, there are many different safety features that can be involved. Coolant systems can use natural circulation – convection – so there are no pumps, no moving parts that could break down, and they keep removing decay heat after the reactor shuts down, so that the core doesn’t overheat and melt. Negative temperature coefficients in the moderators and the fuels keep the fission reactions under control, causing the fission reactions to slow down as temperature increases.[16]

Some SMR designs have underground placement of the reactors and spent-fuel storage pools, which provides more security. Smaller reactors would be easier to upgrade quickly, require a permanent workforce, and have better quality controls.[17]

Economics

A key driver of SMRs are the alleged improved economies of scale, compared to larger reactors, that stem from the ability to prefabricate them in a manufacturing plant/factory. A key disadvantage, however, is that these improved economics can only be realised if the factory is built in the first place, and this is likely to require initial orders for 40-70 units, which some experts think unlikely.[18]

Another economic advantage of SMR is that the initial cost of building a power plant using SMR is much less than that of constructing a much more complex, non-modular, large nuclear plant. This makes SMR a smaller-risk venture for power companies than other nuclear power plants.[19]

Licensing

A major barrier is the licensing process, historically developed for large reactors, preventing the simple deployment of several identical units in different countries.[20] In particular the US Nuclear Regulatory Commission process for licensing has focused mainly on large commercial reactors. The design and safety specifications, staffing requirements and licensing fees have all been geared toward reactors with an electrical output of more than 700MWe.[21]

Licensing for SMRs has been an ongoing discussion. There was a workshop in October 2009 about licensing difficulties and another in June 2010, with a US congressional hearing in May 2010. With growing worries about climate change and greenhouse gas emissions, added to problems with hydrocarbon supplies from foreign countries and accidents like the BP oil rig explosion in the Gulf of Mexico, many US government agencies are working to push the development of different licensing for SMRs.[22]

Non-proliferation

Nuclear proliferation, or the use of nuclear materials to create weapons, is a concern for small modular reactors. As SMRs have lower generation capacity and are physically small, they are intended to be deployed in many more locations than existing nuclear plants. This means both at more sites in existing nuclear power states, and in more countries that previously did not have nuclear plants. It is also intended that SMR sites have much lower staffing levels than current nuclear plants. Because of the increased number of sites, with fewer staff, physical protection and security becomes an increased challenge which could increase proliferation risks.[23][24]

Many SMRs are designed to lessen the danger of materials being stolen or misplaced.

Nuclear reactor fuel can be low-enriched uranium, with a concentration of less than 20% of fissile 235

U.

This low quantity, non-weapons-grade uranium makes the fuel less desirable for weapons production.

Once the fuel has been irradiated, the fission products mixed with the fissile materials are highly radioactive and require special handling to remove safely, another non-proliferation feature.

Some SMR designs are intended to have lifetime cores so the SMRs do not need refuelling. This improves proliferation resistance by not requiring any on-site nuclear fuel handling. But it also means that there will be large inventories of fissile material within the SMRs to sustain a long lifetime, which could make it a more attractive proliferation target. A 200 MWe 30-year core life light water SMR could contain about 2.5 tonnes of plutonium toward the end of its working life.[24]

Light-water reactors designed to run on the thorium fuel cycle offer increased proliferation resistance compared to conventional uranium cycle, though molten salt reactors have a substantial risk.[25][26]

The modular construction of SMRs is another useful feature. Because the reactor core is often constructed completely inside a central manufacturing facility, fewer people have access to the fuel before and after irradiation.

Reactor designs

There are numerous new reactor designs being generated all over the world. A small selection of the current SMR designs is listed below.

| Name | Gross power (MWe) | Type | Producer | Status |

|---|---|---|---|---|

| 4S | 10–50 | SFR | Toshiba, Japan | Detailed Design |

| ABV-6 | 6–9 | PWR | OKBM Afrikantov, Russia | Detailed Design |

| ANGSTREM[28] | 6 | LFR | OKB Gidropress, Russia | Conceptual Design |

| mPower | 195 | PWR | Babcock & Wilcox, USA | |

| BREST-OD-300[29] | 300 | LFR | Atomenergoprom, Russia | Detailed Design |

| CAREM | 27–30 | PWR | CNEA & INVAP, Argentina | Under Construction |

| CUBE-100 | 100 | MSR | Seaborg Technologies, Denmark | Conceptual Design |

| EGP-6 | 11 | RBMK | IPPE & Teploelektroproekt Design, Russia | Operating (not actively marketed due to legacy design, will be taken out of operation permanently in 2019) |

| ELENA[lower-alpha 1] | 0.068 | PWR | Kurchatov Institute, Russia | Conceptual Design |

| Flexblue | 160 | PWR | Areva TA / DCNS group, France | Conceptual Design |

| Fuji MSR | 200 | MSR | International Thorium Molten Salt Forum (ITMSF), Japan | Conceptual Design(?) |

| GT-MHR | 285 | HTGR | OKBM Afrikantov, Russia | Conceptual Design Completed |

| G4M | 25 | LFR | Gen4 Energy, USA | Conceptual Design |

| IMSR400 | 185–192 | MSR | Terrestrial Energy, Inc.,[32] Canada | Conceptual Design |

| IRIS | 335 | PWR | Westinghouse-led, international | Basic Design |

| KLT-40S | 35 | PWR | OKBM Afrikantov, Russia | Under Construction |

| MHR-100 | 25–87 | HTGR | OKBM Afrikantov, Russia | Conceptual Design |

| MHR-T[lower-alpha 2] | 4х205.5 | HTGR | OKBM Afrikantov, Russia | Conceptual Design |

| MRX | 30–100 | PWR | JAERI, Japan | Conceptual Design |

| NP-300 | 100–300 | PWR | Areva TA, France | Conceptual Design |

| NuScale | 45–50 | LWR | NuScale Power LLC, USA | Licensing Stage |

| PBMR-400 | 165 | HTGR | Eskom, South Africa, et al. | Detailed Design |

| RITM-200 | 50 | PWR | OKBM Afrikantov, Russia | Under Construction |

| SMART | 100 | PWR | KAERI, S. Korea | Licensed |

| SMR-160 | 160 | PWR | Holtec International, USA | Conceptual Design |

| SVBR-100[33][34] | 100 | LFR | OKB Gidropress, Russia | Detailed Design |

| SSR-W | 300-1000 | MSR | Moltex Energy,[35] UK | Conceptual Design |

| S-PRISM | 311 | FBR | GE Hitachi Nuclear Energy | Detailed Design |

| TerraPower | 10 | TWR | Intellectual Ventures - Bellevue, WA USA | Conceptual Design |

| U-Battery | 4 | HTGR | U-Battery consortium,[lower-alpha 3] UK | Conceptual Design[36] |

| VBER-300 | 325 | PWR | OKBM Afrikantov, Russia | Licensing Stage |

| VK-300 | 250 | BWR | Atomstroyexport, Russia | Detailed Design |

| VVER-300 | 300 | BWR | OKB Gidropress, Russia | Conceptual Design |

| Westinghouse SMR | 225 | PWR | Westinghouse Electric Company, USA | Preliminary Design Completed |

| Xe-100 | 35 | HTGR | X-energy,[37] USA | Conceptual design development |

| Updated as of 2014. Some reactors are not included in IAEA Report. Not all IAEA reactors are listed yet. | ||||

- ↑ If completed, ELENA would be the smallest commercial nuclear reactor ever built.[30][31]

- ↑ Multi-unit complex based on the GT-MHR reactor design, designed primarily for hydrogen production.

- ↑ Urenco Group, Atkins, Amec Foster Wheeler, Laing O'Rourke, Cammell Laird, Nuclear AMRC

Proposed sites

United Kingdom

In 2016 it was reported that the UK Government was assessing sites for deploying SMRs in Wales - including the former Trawsfynydd nuclear power station - and on the site of former nuclear or coal-fired power stations in Northern England. Existing nuclear sites including Bradwell, Hartlepool, Heysham, Oldbury, Sizewell, Sellafield and Wylfa are thought to be possibilities.[38]

United States

The Tennessee Valley Authority announced it will be submitting an Early Site Permit Application (ESPA) to the Nuclear Regulatory Commission in May 2016 for potentially siting an SMR at its Clinch River Site in Tennessee. This ESPA would be valid for up to 20 years, and addresses site safety, environmental protection and emergency preparedness associated. TVA has not made a technology selection so this ESPA would be applicable for any of the light-water reactor SMR designs under development in the United States.[39]

The Utah Associated Municipal Power Systems (UAMPS) announced a teaming partnership with Energy Northwest to explore siting a NuScale Power reactor in Idaho, possibly on the Department of Energy's Idaho National Laboratory.[40]

The Galena Nuclear Power Plant in Galena, Alaska was a proposed micro nuclear reactor installation intended to reduce the costs and environmental pollution required to power the town. It was a potential deployment for the Toshiba 4S reactor.

References

- ↑ "Small Modular Reactors", Department of Energy – Office of Nuclear Energy

- ↑ Report to Congress 2001, p. 8

- ↑ Locatelli, Giorgio; Fiordaliso, Andrea; Boarin, Sara; Ricotti, Marco E. (2017-05-01). "Cogeneration: An option to facilitate load following in Small Modular Reactors". Progress in Nuclear Energy. 97: 153–161. doi:10.1016/j.pnucene.2016.12.012.

- ↑ "Safety of Nuclear Power Reactors", World Nuclear Association

- ↑ INEA, NEA, IEA. "Innovative Nuclear Reactor Development: Opportunities for International Co-operation", OECD Nuclear Energy Agency

- 1 2 Carlson, J. "Fast Neutron Reactors", World Nuclear Association

- 1 2 Wilson, P.D. "Nuclear Power Reactors", World Nuclear Association

- ↑ brian wang (2011-10-13). "Flibe Energy Liquid Flouride [sic] Thorium Reactor Company". Nextbigfuture.com. Retrieved 2012-12-18.

- ↑ "Nuclear Process Heat for Industry", World Nuclear Association

- ↑ "The Galena Project Technical Publications", pg. 22, Burns & Roe

- ↑ Locatelli, Giorgio; Fiordaliso, Andrea; Boarin, Sara; Ricotti, Marco E. (2017-05-01). "Cogeneration: An option to facilitate load following in Small Modular Reactors". Progress in Nuclear Energy. 97: 153–161. doi:10.1016/j.pnucene.2016.12.012.

- ↑ Locatelli, Giorgio; Fiordaliso, Andrea; Boarin, Sara; Ricotti, Marco E. (2017-05-01). "Cogeneration: An option to facilitate load following in Small Modular Reactors". Progress in Nuclear Energy. 97: 153–161. doi:10.1016/j.pnucene.2016.12.012.

- ↑ Locatelli, Giorgio; Boarin, Sara; Pellegrino, Francesco; Ricotti, Marco E. (2015-02-01). "Load following with Small Modular Reactors (SMR): A real options analysis". Energy. 80: 41–54. doi:10.1016/j.energy.2014.11.040.

- ↑ Section 5.3, WASH 1097 "The Use of Thorium in Nuclear Power Reactors", available as a PDF from Liquid-Halide Reactor Documents database: http://www.energyfromthorium.com/pdf/

- ↑ Wald, M. "TR10: Traveling Wave Reactor", Technology Review

- ↑ DOE-HDBK-1019 1993, pp. 23–29

- ↑ [Moniz, Ernest. "Why We Still Need Nuclear Power: Making Clean Energy Safe and Affordable." Foreign Affairs 90, no. 6 (November 2011): 83-94.]

- ↑ Harrabin, Roger (23 March 2016). "The nuclear industry: a small revolution". BBC News. British Broadcasting Corporation. Retrieved 3 April 2016.

- ↑ Black, R. "Bringing Small Modular Reactors (SMRs) to Domestic Markets: DOE Presentation to Foundation for Nuclear Studies", Nuclear Foundation

- ↑ Sainati, Tristano; Locatelli, Giorgio; Brookes, Naomi (2015-03-15). "Small Modular Reactors: Licensing constraints and the way forward". Energy. 82: 1092–1095. doi:10.1016/j.energy.2014.12.079.

- ↑ Rysavy, C., Rhyne, S., Shaw, R. "Small Modular Reactors", ABA Section of Environment, Energy and Resources – Special Committee on Nuclear Power

- ↑ Jones, Richard M. (18 June 2010). "Positive Response to Administration's Nuclear Energy Strategy" (66).

- ↑ Greneche, Dominique (18 June 2010), Proliferation issues related to the deployment of Small & Medium Size reactors (SMRs) (presentation), AREVA, retrieved 23 March 2017

- 1 2 Glaser, Alexander (5 November 2014), Small Modular Reactors - Technology and Deployment Choices (presentation), NRC, retrieved 23 March 2017

- ↑ Kang, J.; Von Hippel, F. N. (2001). "U‐232 and the proliferation‐resistance of U‐233 in spent fuel". Science & Global Security. 9: 1. doi:10.1080/08929880108426485. "Archived copy" (PDF). Archived from the original (PDF) on 2014-12-03. Retrieved 2015-03-02.

- ↑ Ashley, Stephen (2012). "Thorium fuel has risks". Nature. 492: 31–33. doi:10.1038/492031a.

- ↑ IAEA Report

- ↑ "THE ANGSTREM PROJECT: PRESENT STATUS AND DEVELOPMENT ACTIVITIES" (PDF). Retrieved 22 June 2017.

- ↑ https://smr.inl.gov/Document.ashx?path=DOCS%2FSMR+technologies%2FBREST%2FDesign_features_of+BREST+Reactors.pdf

- ↑ http://www.iaea.org/nuclearenergy/nuclearpower/Downloadable/SMR/files/4_UPDATED_STATUS_ON_GLOBAL_SMR_DEVELOPMENT__as_of_September_2014.pdf

- ↑ http://www.iaea.org/nuclearenergy/nuclearpower/Downloadable/SMR/files/IAEA_SMR_Booklet_2014.pdf

- ↑ "Terrestrial Energy | Integral Molten Salt Reactor Technology". Terrestrial Energy. Retrieved 2016-11-12.

- ↑ http://www.gidropress.podolsk.ru/files/booklets/en/svbr75_100_en.pdf

- ↑ http://www.iaea.org/NuclearPower/Downloadable/Meetings/2011/2011-07-04-07-08-WS-NPTD/2_RUSSIA_SVBR_AKME-eng_Antysheva.pdf

- ↑ "Moltex Energy | Safer Cheaper Cleaner Nuclear | Stable Salt Reactors | SSR". moltexenergy.com. Retrieved 2018-04-10.

- ↑ Onstad, Eric (8 Feb 2013). "Nuclear fuel firm champions "plug-and-play" micro reactors". Reuters. Retrieved 3 April 2016.

- ↑ "Energy Department Announces New Investments in Advanced Nuclear Power Reactors..." US Department of Energy. Retrieved 16 January 2016.

- ↑ McCann, Kate (2 April 2016). "Mini nuclear power stations in UK towns move one step closer". The Sunday Telegraph. Retrieved 3 April 2016.

- ↑ "TVA - Small Modular Reactors". www.tva.gov. Retrieved 2016-04-08.

- ↑ "Carbon Free". www.uamps.com. Retrieved 2016-04-08.

Further reading

- Office of Nuclear Energy, Science and Technology (January 1993). "DOE Fundamentals Handbook: Nuclear Physics and Reactor Theory" (PDF). U.S. Department of Energy. DOE-HDBK-1019, DE93012223. Archived from the original (PDF) on 2012-11-09.

- Office of Nuclear Energy, Science and Technology (May 2001). "Report to Congress on Small Modular Nuclear Reactors" (PDF). U.S. Department of Energy. Archived from the original (PDF) on 2011-07-16.

External links

| Wikimedia Commons has media related to Small modular reactors. |