Molten salt reactor

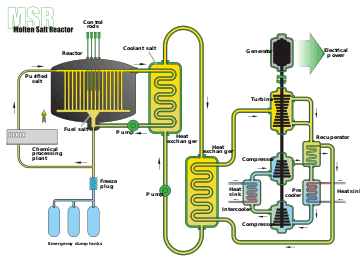

A molten salt reactor (MSR) is a class of nuclear fission reactor in which the primary nuclear reactor coolant and/or the fuel is a molten salt mixture. MSRs offer multiple advantages over conventional nuclear power plants, although for historical reasons, they have not been deployed.

MSRs used to be "expensive, required highly enriched fuel, and had a low power density"[1], In comparison, they are now "cleaner, more compact, more affordable"[1], run at higher temperatures, have better thermodynamic efficiency, and perform in low (atmospheric) vapour pressure.[2]

The concept was first established in the 1950s. The early Aircraft Reactor Experiment was primarily motivated by the small size that the technique offered, while the Molten-Salt Reactor Experiment was a prototype for a thorium fuel cycle breeder nuclear power plant. The increased research into Generation IV reactor designs renewed interest in the technology.[3]

History

Aircraft reactor experiment

MSR research started with the U.S. Aircraft Reactor Experiment (ARE) in support of the U.S. Aircraft Nuclear Propulsion program. ARE was a 2.5 MWth nuclear reactor experiment designed to attain a high energy density for use as an engine in a nuclear-powered bomber.

The project included experiments, including high temperature and engine tests collectively called the Heat Transfer Reactor Experiments: HTRE-1, HTRE-2 and HTRE-3 at the National Reactor Test Station (now Idaho National Laboratory) as well as an experimental high-temperature molten salt reactor at Oak Ridge National Laboratory – the ARE.

ARE used molten fluoride salt NaF-ZrF4-UF4 (53-41-6 mol%) as fuel, moderated by beryllium oxide (BeO). Liquid sodium was a secondary coolant.

The experiment had a peak temperature of 860 °C. It produced 100 MWh over nine days in 1954. This experiment used Inconel 600 alloy for the metal structure and piping.[4]

An MSR was operated at the Critical Experiments Facility of the Oak Ridge National Laboratory in 1957. It was part of the circulating-fuel reactor program of the (Pratt & Whitney Aircraft Company (PWAC). This was called Pratt and Whitney Aircraft Reactor-1 (PWAR-1). The experiment was run for a few weeks and at essentially zero power, although it reached criticality. The operating temperature was held constant at approximately 675 °C (1,250 °F). The PWAR-1 used NaF-ZrF4-UF4 as the primary fuel and coolant. It was one of three critical MSRs ever built.[5]

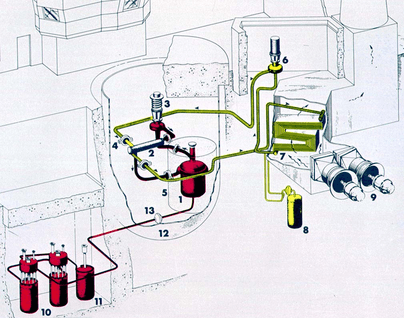

Molten-salt reactor experiment

Oak Ridge National Laboratory (ORNL) took the lead in researching MSRs through the 1960s. Much of their work culminated with the Molten-Salt Reactor Experiment (MSRE). MSRE was a 7.4 MWth test reactor simulating the neutronic "kernel" of a type of epithermal thorium molten salt breeder reactor called the liquid fluoride thorium reactor (LFTR). The large (expensive) breeding blanket of thorium salt was omitted in favor of neutron measurements.

MSRE's piping, core vat and structural components were made from Hastelloy-N, moderated by pyrolytic graphite. It went critical in 1965 and ran for four years. Its fuel was LiF-BeF2-ZrF4-UF4 (65-29-5-1). The graphite core moderated it. Its secondary coolant was FLiBe (2LiF-BeF2). It reached temperatures as high as 650 °C and achieved the equivalent of about 1.5 years of full power operation.

Oak Ridge National Laboratory molten salt breeder reactor

The culmination of the ORNL research during the 1970–1976 timeframe resulted in a molten salt breeder reactor (MSBR) design. Fuel was to be LiF-BeF2-ThF4-UF4 (72-16-12-0.4) with graphite moderator. The secondary coolant was to be NaF-NaBF4. Its peak operating temperature was to be 705 °C.[6] It would follow a 4-year replacement schedule. The MSR program closed down in the early 1970s in favor of the liquid metal fast-breeder reactor (LMFBR),[7] after which research stagnated in the United States.[8][9] As of 2011, ARE and MSRE remained the only molten-salt reactors ever operated.

The MSBR project received funding until 1976. Inflation-adjusted to 1991 dollars, the project received $38.9 million from 1968 to 1976.[10]

Officially, the program was cancelled because:

- The political and technical support for the program in the United States was too thin geographically. Within the United States the technology was well understood only in Oak Ridge.[7]

- The MSR program was in competition with the fast breeder program at the time, which got an early start and had copious government development funds with contracts that benefited many parts of the country. When the MSR development program had progressed far enough to justify an expanded program leading to commercial development, the AEC could not justify the diversion of substantial funds from the LMFBR to a competing program.[7]

Oak Ridge National Laboratory denatured molten salt reactor (DMSR)

In 1980, the engineering technology division at Oak Ridge National Laboratory published a paper entitled "Conceptual Design Characteristics of a Denatured Molten-Salt Reactor with Once-Through Fueling." In it, the authors "examine the conceptual feasibility of a molten-salt power reactor fueled with denatured uranium-235 (i.e. with low-enriched uranium) and operated with a minimum of chemical processing." The main priority behind the design characteristics was proliferation resistance.[11] Although the DMSR can theoretically be fueled partially by thorium or plutonium, fueling solely with low enriched uranium (LEU) helps maximize proliferation resistance.

Other important goals of the DMSR were to minimize R&D and to maximize feasibility. The Generation IV international Forum (GIF) includes "salt processing" as a technology gap for molten salt reactors.[12] The DMSR requires minimal chemical processing because it is a burner rather than a breeder. Both reactors built at ORNL were burner designs. In addition, the choices to use graphite for neutron moderation and enhanced Hastelloy-N for piping simplified the design and reduced R&D.

United Kingdom

The UK's Atomic Energy Research Establishment (AERE) were developing an alternative MSR design across its National Laboratories at Harwell, Culham, Risley and Winfrith. AERE opted to focus on a lead-cooled 2.5 GWe Molten Salt Fast Reactor (MSFR) concept using a chloride.[13] They also researched helium gas as a coolant.[14][15]

The UK MSFR would be fuelled by plutonium, a fuel considered to be 'free' by the program's research scientists, because of the UK's plutonium stockpile.

Despite their different designs, ORNL and AERE maintained contact during this period with information exchange and expert visits. Theoretical work on the concept was conducted between 1964 and 1966, while experimental work was ongoing between 1968 and 1973. The program received annual government funding of around £100,000-£200,000 (equivalent to £2m-£3m in 2005). This funding came to an end in 1974, partly due to the success of the Prototype Fast Reactor at Dounreay which was considered a priority for funding as it went critical in the same year.[13]

Soviet Union

In the USSR, a molten-salt reactor research program was started in the second half of the 1970s at the Kurchatov Institute. It included theoretical and experimental studies, particularly the investigation of mechanical, corrosion and radiation properties of the molten salt container materials. The main findings supported the conclusion that no physical nor technological obstacles prevented the practical implementation of MSRs.[16] A reduction in activity occurred after 1986 due to the Chernobyl accident, along with a general stagnation of nuclear power and the nuclear industry.[17](p381)

Twenty-first century

MSR interest resumed in the new millennium with continuing delays in fusion power and other nuclear power programs.

The LFTR design was strongly supported by Alvin Weinberg, who patented the light-water reactor and was a director of the U.S.'s Oak Ridge National Laboratory. In 2016 Nobel prize winning physicist Carlo Rubbia, former Director General of CERN, claimed that one of the main reasons why research was cut is that thorium is difficult to turn into a nuclear weapon.[18]

Thorium is not for tomorrow but unless you do any development, it will not get there. — Dr Carlo Rubbia, Nobel Laureate and former Director General of CERN, January 2016[18]

Commercial/national/international projects

Canada

Terrestrial Energy Inc. (TEI), a Canadian-based company, is developing a DMSR design called the Integral Molten Salt Reactor (IMSR). The IMSR is designed to be deployable as a small modular reactor (SMR). Their design currently undergoing licensing is 400MW thermal (190MW electrical). With high operating temperatures, the IMSR has applications in industrial heat markets as well as traditional power markets. The main design features include neutron moderation from graphite, fueling with low-enriched uranium and a compact and replaceable Core-unit. Decay heat is removed passively using nitrogen (with air as an emergency alternative). The latter feature permits the operational simplicity necessary for industrial deployment.[19]

Terrestrial completed the first phase of a prelicensing review by the Canadian Nuclear Safety Commission in 2017, which provided a regulatory opinion that the design features are generally safe enough to eventually obtain a license to construct the reactor.[20]

China

China initiated a thorium molten-salt reactor research project in January 2011.[21] A 100-MW demonstrator of the solid fuel version (TMSR-SF), based on pebble bed technology, was to be ready by 2024. Initially, a 10-MW pilot and a larger demonstrator of the liquid fuel (TMSR-LF) variant were targeted for 2024 and 2035 respectively.[22][23] China then accelerated its program to build two 12 MW reactors underground at Wuwei research facilities in Gansu Province by 2020.[24] Heat from the reaction would be used to produce electricity, hydrogen, industrial chemicals, desalination and minerals.[24] The project also seeks to test new corrosion resistant materials.[24]

In 2017, ANSTO/Shanghai Institute Of Applied Physics announced the creation of a NiMo-SiC alloy for use in MSRs.[25][26]

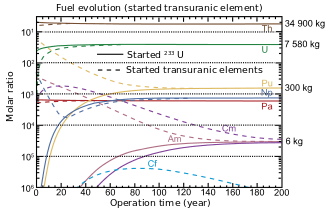

Denmark

Seaborg Technologies is developing the core for a Molten Salt Waste-burner (MSW). The MSW is a high temperature, single salt, thermal MSR designed to go critical on a combination of thorium and nuclear waste from conventional nuclear reactors. The MSW design is modular. The reactor core is estimated to be replaced every 6–10 years. During operation, the fuel will not be replaced and will burn for the entire 60-year power plant lifetime. The first version of the Seaborg core is planned to produce 50 MWth power and could consume approximately 1 ton (not considering natural decays) of transuranic waste. After 60 years the 233U concentration in the fuel salt is high enough to initiate a closed thorium fuel cycle in the next generation power plant.[27]

France

The CNRS project EVOL (Evaluation and viability of liquid fuel fast reactor system) project, with the objective of proposing a design of the MSFR (Molten Salt Fast Reactor),[28] released its final report in 2014.[29]R& Various MSR projects like FHR, MOSART, MSFR, and TMSR have common R&D themes.[30]

The EVOL project will be continued by the EU-funded Safety Assessment of the Molten Salt Fast Reactor (SAMOFAR) project, in which several European research institutes and universities collaborate.[31]

Germany

The German Institute for Solid State Nuclear Physics in Berlin has proposed the Dual fluid reactor as a concept for a fast breeder lead-cooled MSR. The original MSR concept used the fluid salt to provide the fission materials and also to remove the heat. Thus it had problems with the needed flowspeed. Using 2 different fluids in separate circles solves the problem.

India

In 2015, Indian researchers published a MSR design,[32] as an alternative path to thorium-based reactors, according to India's three-stage nuclear power programme.[33]

Japan

The Fuji Molten Salt Reactor is a 100 to 200 MWe LFTR, using technology similar to the Oak Ridge project. A consortium including members from Japan, the U.S. and Russia are developing the project. The project would likely take 20 years to develop a full size reactor,[34] but the project seems to lack funding.[35]

Russia

The Russian MBIR is a planned 150 MWt, sodium-cooled fast reactor. It is to be a multi-loop research reactor for testing lead, lead-bismuth and gas coolants, with a MOX (mixed uranium and plutonium oxide) fuel. An on-site, pyrochemical, closed fuel cycle facility is planned. The reactor is planned to begin operation in 2020. As planned, it wil be the world's most-powerful research reactor.[36]

United Kingdom

The Alvin Weinberg Foundation is a British non-profit organization founded in 2011, dedicated to raising awareness about the potential of thorium energy and LFTR. It was formally launched at the House of Lords on 8 September 2011.[37][38][39] It is named after American nuclear physicist Alvin M. Weinberg, who pioneered thorium MSR research.

A study on MSRs completed in July 2015 considered the feasibility of developing a pilot scale demonstration MSR in the UK. A review of potential UK sites is given along with an insight into the UK regulatory process for innovative reactor technology. The technical review of six MSR designs led to the selection of the Stable Salt Reactor, designed by Moltex Energy, as most suitable for UK implementation.[40] However, Moltex "failed to get engagement from the UK government quickly enough".[41]

United States

Idaho National Laboratory designed a molten-salt-cooled, molten-salt-fuelled reactor with a prospective output of 1000 MWe.[42]

Kirk Sorensen, former NASA scientist and chief nuclear technologist at Teledyne Brown Engineering, is a long-time promoter of the thorium fuel cycle, coining the term liquid fluoride thorium reactor. In 2011, Sorensen founded Flibe Energy, a company aimed at developing 20–50 MW LFTR reactor designs to power military bases. (It is easier to approve novel military designs than civilian power station designs in the US nuclear regulatory environment).[43][44][45][46]

Transatomic Power was created by Ph.D. students from MIT including CEO Leslie Dewan and Mark Massie, and Russ Wilcox of E Ink.[47] They are pursuing what they term a Waste-Annihilating Molten Salt Reactor (acronym WAMSR), intending to consume existing spent nuclear fuel.[48] Transatomic received venture capital funding in early 2015.[49]

In January 2016, the United States Department of Energy announced a $80m award fund to develop Generation IV reactor designs.[50] One of the two beneficiaries, Southern Company will use the funding to develop a Molten Chloride Fast Reactor (MCFR), a type of MSR developed earlier by British scientists.[13]

Design

Nuclear reactors can be categorized in various ways. MSR designs participate in many of those categories. MSRs can be burners or breeders. They can be fast or thermal or epithermal.[51] Thermal reactors typically employ a moderator (usually graphite) to slow the neutrons down and moderate temperature. They can accept a variety of fuels (low-enriched uranium, thorium, depleted uranium, waste products)[52] and coolants (fluoride, chloride, lithium, beryllium, mixed). Fuel can be solid or liquid.[51] Fuel cycle can be either closed or once-through.[51] They can be monolithic or modular, large or small. The reactor can adopt a loop, modular or integral configuration. Variations include:

Liquid-salt very-high-temperature reactor

This approach involves using a fluoride-salt as the coolant. Both the traditional MSR and the very high temperature reactor (VHTR) were selected as potential designs for study under the Generation Four Initiative (GEN-IV). One version of the VHTR under study was the Liquid-Salt Very-High-Temperature Reactor (LS-VHTR), also commonly called the Advanced High-Temperature Reactor (AHTR).

It uses liquid salt as a coolant in the primary loop, rather than a single helium loop. It relies on "TRISO" fuel dispersed in graphite. Early AHTR research focused on graphite in the form of graphite rods that would be inserted in hexagonal moderating graphite blocks, but current studies focus primarily on pebble-type fuel. The LS-VHTR can work at very high temperatures (the boiling point of most molten salt candidates is >1400 °C); low-pressure cooling that can be used to match hydrogen production facility conditions (most thermochemical cycles require temperatures in excess of 750 °C); better electric conversion efficiency than a helium-cooled VHTR operating in similar conditions; passive safety systems and better retention of fission products in the event of an accident. This concept is now referred to as "fluoride salt-cooled high-temperature reactor" (FHR).[53]

Liquid fluoride thorium reactor

Reactors containing molten thorium salt, called liquid fluoride thorium reactors (LFTR), would tap the thorium fuel cycle. Private companies from Japan, Russia, Australia and the United States, and the Chinese government, have expressed interest in developing this technology.[35][43][21]

Advocates estimate that five hundred metric tons of thorium could supply U.S. energy needs for one year.[54] The U.S. Geological Survey estimates that the largest known U.S. thorium deposit, the Lemhi Pass district on the Montana-Idaho border, contains thorium reserves of 64,000 metric tons.[55]

Coolant

MSRs can be cooled in various ways, including using molten salts.

Molten-salt-cooled solid-fuel reactors are variously called "molten salt reactor system" in the Generation IV proposal, Molten Salt Converter Reactors (MSCR), advanced high-temperature reactors (AHTRs), or fluoride high-temperature reactors (FHR, preferred DOE designation).[56]

FHRs cannot reprocess fuel easily and have fuel rods that need to be fabricated and validated, requiring up to twenty years from project inception. FHR retains the safety and cost advantages of a low-pressure, high-temperature coolant, also shared by liquid metal cooled reactors. Notably, steam is not created in the core (as is present in BWRs), and no large, expensive steel pressure vessel (as required for PWRs). Since it can operate at high temperatures, the conversion of the heat to electricity can use an efficient, lightweight Brayton cycle gas turbine.

Much of the current research on FHRs is focused on small, compact heat exchangers that reduce molten salt volumes and associated costs.[57]

Molten salts can be highly corrosive and corrosivity increases with temperature. For the primary cooling loop, a material is needed that can withstand corrosion at high temperatures and intense radiation. Experiments show that Hastelloy-N and similar alloys are suited to these tasks at operating temperatures up to about 700 °C. However, operating experience is limited. Still higher operating temperatures are desirable – at 850 °C thermochemical production of hydrogen becomes possible. Materials for this temperature range have not been validated, though carbon composites, molybdenum alloys (e.g. TZM), carbides, and refractory metal based or ODS alloys might be feasible.

Dual-fluid molten salt reactors

A prototypical example of a dual fluid reactor is the lead-cooled, salt-fueled reactor.

Fused salt selection

The salt mixtures are chosen to make the reactor safer and more practical.

Fluorine

Fluorine has only one stable isotope (F-19), and does not easily become radioactive under neutron bombardment. Compared to chlorine and other halides, fluorine also absorbs fewer neutrons and slows ("moderates") neutrons better. Low-valence fluorides boil at high temperatures, though many pentafluorides and hexafluorides boil at low temperatures. They must be very hot before they break down into their constituent elements. Such molten salts are "chemically stable" when maintained well below their boiling points. Fluoride salts dissolve poorly in water, and do not form burnable hydrogen.

Chlorine

Chlorine has two stable isotopes (35

Cl and 37

Cl), as well as a slow-decaying isotope between them which facilitates neutron absorption by 35

Cl.

Chlorides permit fast breeder reactors to be constructed. Much less research has been done on reactor designs using chloride salts. Chlorine, unlike fluorine, must be purified to isolate the heavier stable isotope, chlorine-37, thus reducing production of sulfur tetrafluoride that occurs when chlorine-35 absorbs a neutron to become chlorine-36, then degrades by beta decay to sulfur-36.

Lithium

Lithium must be in the form of purified 7

Li, because 6

Li effectively captures neutrons and produces tritium. Even if pure 7Li is used, salts containing lithium cause significant tritium production, comparable with heavy water reactors.

Mixtures

Reactor salts are usually close to eutectic mixtures to reduce their melting point. A low melting point simplifies melting the salt at startup and reduces the risk of the salt freezing as it is cooled in the heat exchanger.

Due to the high "redox window" of fused fluoride salts, the redox potential of the fused salt system can be changed. Fluorine-Lithium-Beryllium ("FLiBe") can be used with beryllium additions to lower the redox potential and almost eliminate corrosion. However, since beryllium is extremely toxic, special precautions must be engineered into the design to prevent its release into the environment. Many other salts can cause plumbing corrosion, especially if the reactor is hot enough to make highly reactive hydrogen.

To date, most research has focused on FLiBe, because lithium and beryllium are reasonably effective moderators and form a eutectic salt mixture with a lower melting point than each of the constituent salts. Beryllium also performs neutron doubling, improving the neutron economy. This process occurs when the beryllium nucleus emits two neutrons after absorbing a single neutron. For the fuel carrying salts, generally 1% or 2% (by mole) of UF4 is added. Thorium and plutonium fluorides have also been used.

| Material | Total neutron capture relative to graphite (per unit volume) | Moderating ratio (Avg. 0.1 to 10 eV) |

|---|---|---|

| Heavy water | 0.2 | 11449 |

| ZrH[59][60][61] | ~0.2 | ~0 if <0.14 eV, ~11449 if >0.14 eV |

| Light water | 75 | 246 |

| Graphite | 1 | 863 |

| Sodium | 47 | 2 |

| UCO | 285 | 2 |

| UO2 | 3583 | 0.1 |

| 2LiF–BeF2 | 8 | 60 |

| LiF–BeF2–ZrF4 (64.5–30.5–5) | 8 | 54 |

| NaF–BeF2 (57–43) | 28 | 15 |

| LiF–NaF–BeF2 (31–31–38) | 20 | 22 |

| LiF–ZrF4 (51–49) | 9 | 29 |

| NaF–ZrF4 (59.5–40.5) | 24 | 10 |

| LiF-NaF–ZrF4 (26–37–37) | 20 | 13 |

| KF–ZrF4 (58–42) | 67 | 3 |

| RbF–ZrF4 (58–42) | 14 | 13 |

| LiF–KF (50–50) | 97 | 2 |

| LiF–RbF (44–56) | 19 | 9 |

| LiF–NaF–KF (46.5–11.5–42) | 90 | 2 |

| LiF–NaF–RbF (42–6–52) | 20 | 8 |

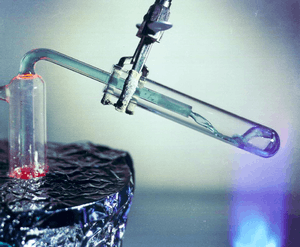

Fused salt purification

Techniques for preparing and handling molten salt were first developed at ORNL.[62] The purpose of salt purification is to eliminate oxides, sulfur and metal impurities. Oxides could result in the deposition of solid particles in reactor operation. Sulfur must be removed because of its corrosive attack on nickel-based alloys at operational temperature. Structural metal such as chromium, nickel, and iron must be removed for corrosion control.

A water content reduction purification stage using HF and helium sweep gas was specified to run at 400 °C. Oxide and sulfur contamination in the salt mixtures were removed using gas sparging of HF – H2 mixture, with the salt heated to 600 °C.[62](p8) Structural metal contamination in the salt mixtures were removed using hydrogen gas sparging, at 700 °C.[62](p26) Solid ammonium hydrofluoride was proposed as a safer alternative for oxide removal.[63]

Fused salt processing

The possibility of online processing can be an MSR advantage. Continuous processing would reduce the inventory of fission products, control corrosion and improve neutron economy by removing fission products with high neutron absorption cross-section, especially xenon. This makes the MSR particularly suited to the neutron-poor thorium fuel cycle. Online fuel processing can introduce risks of fuel processing accidents,[64](p15) which can trigger release of radio isotopes.

In some thorium breeding scenarios, the intermediate product Protactinium233

Pa would be removed from the reactor and allowed to decay into highly pure 233

U, an attractive bomb-making material. More modern designs propose to use a lower specific power or a separate thorium breeding blanket. This dilutes the protactinium to such an extent that few protactinium atoms absorb a second neutron or, via a (n, 2n) reaction (in which an incident neutron is not absorbed but instead knocks a neutron out of the nucleus), generate 232

U. Because 232

U has a short half-life and its decay chain contains hard gamma emitters, it makes the isotopic mix of uranium less attractive for bomb-making. This benefit would come with the added expense of a larger fissile inventory or a 2-fluid design with a large quantity of blanket salt.

The necessary fuel salt reprocessing technology has been demonstrated, but only at laboratory scale. A prerequisite to full-scale commercial reactor design is the R&D to engineer an economically competitive fuel salt cleaning system.

Safety

MSRs are claimed to provide less safety risk than water-based reactors, for multiple reasons:

Pressure

MSRs operate at low (although above ambient) pressure. In the event of a malfunction, this means that the risks of an explosion are low.

Cooling

Most MSR designs employ passive cooling systems. This means that pumping is not required, removing pump failure risks. If temperature grow too high, the temperature melts a plug that otherwise keeps the molten salt inside the reactor allowing it to drain into an area that disperses the fuel and quenches fission.

Reactor activity is negatively related to temperature. If the reactor gets too hot, fission slows, allowing temperature to cool.

Waste

MSRs can be designed to produce a much smaller volume of much shorter-lived waste products, reducing problems associated with waste disposal and proliferation.

Proliferation

MSRs can be designed to burn (convert to energy) spent nuclear fuel and weapons-related materials and not produce nuclear materials with proliferation risks.

Siting

MSRs can be sited underground such that in the event of a failure or at end-of-life, the operator can safely walk away from the unit.

Fuel reprocessing

Reprocessing refers to the chemical separation of fissionable uranium and plutonium from spent fuel.[65] Such recovery could increase the risk of nuclear proliferation. In the United States the regulatory regime has varied dramatically across administrations.[65]

In the 1971 Molten Salt Breeder Reactor proposal, uranium reprocessing was scheduled every ten days as part of reactor operation.[66](p181) Subsequently, a once-through fueling design was proposed that limited uranium reprocessing to every thirty years at the end of useful salt life.[67](p98) A mixture with 238

U was called for to make sure recovered uranium would not be weapons grade. This design is referred to as denatured molten salt reactor.[68] Absent reprocessing the uranium would be disposed with other fission products.

Comparison to light water reactors

MSRs, especially those with the fuel dissolved in the salt differ considerably from conventional reactors. Reactor core pressure can be low and the temperature much higher. In this respect an MSR is more similar to a liquid metal cooled reactor than to a conventional light water cooled reactor. MSRs are often planned as breeding reactors with a closed fuel cycle – as opposed to the once-through fuel currently used in U.S. nuclear reactors.

Safety concepts rely on a negative temperature coefficient of reactivity and a large possible temperature rise to limit reactivity excursions. As an additional method for shutdown, a separate, passively cooled container below the reactor can be included. In case of problems and for regular maintenance the fuel is drained from the reactor. This stops the nuclear reaction and acts as a second cooling system. Neutron-producing accelerators have been proposed for some super-safe subcritical experimental designs.[69]

Cost estimates from the 1970s were slightly lower than for conventional light-water reactors.[70]

The temperatures of some proposed designs are high enough to produce process heat for hydrogen production or other chemical reactions. Because of this, they are included in the GEN-IV roadmap for further study.[71]

Advantages

MSR offers many potential advantages over current light water reactors:[6]

- Inherently safe design (safety by passive components and the strong negative temperature coefficient of reactivity of some designs). In some designs, the fuel and the coolant are the same fluid, so a loss of coolant removes the reactor's fuel. Unlike steam, fluoride salts dissolve poorly in water, and do not form burnable hydrogen. Unlike steel and solid uranium oxide, molten salts are not damaged by the core's neutron bombardment.

- A low-pressure MSR lacks a LWR's high-pressure radioactive steam and therefore do not experience leaks of radioactive steam and cooling water, and the expensive containment, steel core vessel, piping and safety equipment needed to contain radioactive steam.

- MSRs make closed nuclear fuel cycles cheaper and more practical. If fully implemented, a closed nuclear fuel cycle reduces environmental impacts: Chemical separation turns long-lived actinides back into reactor fuel. The discharged wastes are mostly fission products (nuclear ashes) with short half-lives. This reduces the needed geologic containment to 300 years rather than the tens of thousands of years needed by a light-water reactor's spent nuclear fuel. It also permits the use of more-abundant nuclear fuels, such as thorium.

- The fuel's liquid phase might be pyroprocessed to separate fission products (nuclear ashes) from actinide fuels. This may have advantages over conventional reprocessing, though much development is still needed.

- Fuel rods are not required.

- In new solid-fueled reactor designs, the longest-lead item is the safety testing of fuel element designs. Fuel tests usually must cover several three-year refueling cycles. However, several molten salt fuels have passed validation.

- Some designs can "burn" problematic transuranic elements from traditional solid-fuel nuclear reactors.

- An MSR can react to load changes in less than 60 seconds (unlike "traditional" solid-fuel nuclear power plants that suffer from xenon poisoning).

- Molten salt reactors can run at high temperatures, yielding high production efficiency. This reduces size, expense and environmental impacts.

- MSRs can offer a high "specific power," that is high power at a low mass as demonstrated by ARE.[4] MSR power plants may be suitable for ships.

- A possibly good neutron economy makes the MSR attractive for the neutron poor thorium fuel cycle.

- LWR's (and most other solid-fuel reactors) have no fundamental "off switch", but once the initial criticality is overcome, an MSR is comparatively easy and fast to turn off by letting the freeze plug melt.

Disadvantages

- Little development compared to most Gen IV designs .

- Required onsite chemical plant to manage core mixture and remove fission products.

- Required regulatory changes to deal with radically different design features.

- MSR designs rely on nickel-based alloys to hold the molten salt. Alloys based on nickel and iron are prone to embrittlement under high neutron flux.[67](p83)

- Corrosion risk.[72]

- As a breeder reactor, a modified MSR might be able to produce weapons-grade nuclear material.[73]

- The MSRE and aircraft nuclear reactors used enrichment levels so high that they approach the levels of nuclear weapons. These levels would be illegal in most modern regulatory regimes for power plants. Some modern designs avoid this issue.[74]

- Neutron damage to solid moderator materials can limit the core lifetime of an MSR that makes moderately fast neutrons. For example, the MSRE was designed so that its graphite moderator sticks had very low tolerances, so neutron damage could change their size without damage. "Two fluid" MSR designs are unable to use graphite piping because graphite changes size when it is bombarded with neutrons, and graphite pipes would crack and leak.[6]

See also

References

- 1 2 "The Science - Transatomic". Transatomic. Retrieved 2018-09-22.

- ↑ Williams, Stephen (16 January 2015). "Molten Salt Reactors: The Future of Green Energy?". ZME Science. Retrieved 18 February 2015.

- ↑ "Molten Salt Reactors - World Nuclear Association".

- 1 2 Rosenthal, Murry. An Account of Oak Ridge National Laboratory's Thirteen Nuclear Reactors, ORNL/TM-2009/181.

- ↑ Scott, D.; Alwang, G.W.; Demski, E.F.; Fader, W.J.; Sandin, E.V.; Malenfant, R.E. (1958) A ZERO POWER REFLECTOR-MODERATED REACTOR EXPERIMENT AT ELEVATED TEMPERATURE. Oak Ridge National Lab.

- 1 2 3 Section 5.3, WASH 1097. Energy From Thorium's Document Repository "The Use of Thorium in Nuclear Power Reactors". ORNL.gov

- 1 2 3 MacPherson, H. G. (1985). "The Molten Salt Reactor Adventure" (PDF). Nuclear Science and Engineering. 90: 374–380.

- ↑ Weinberg, Alvin (1997). The First Nuclear Era: The Life and Times of a Technological Fixer. Springer. ISBN 978-1-56396-358-2.

- ↑ "ORNL: The First 50 Years". Retrieved 12 November 2011.

|chapter=ignored (help) - ↑ Cohen, Linda R.; Noll, Roger G. (1991). The Technology pork barrel. Brookings Institution. p. 234. ISBN 0-8157-1508-0. Retrieved 28 February 2012.

- ↑ Engel, J.R. (1980) "Conceptual Design Characteristics of a Denatured Molten-Salt Reactor with Once-Through Fueling." Oak Ridge National Laboratory: Engineering Technology Division.

- ↑ A Technology Roadmap for Generation IV Nuclear Energy Systems. P. 34. U.S. DOE Nuclear Energy Research Advisory Committee and the Generation IV International Forum. Copyright 2002.

- 1 2 3 "The UK's Forgotten Molten Salt Reactor Programme - The Alvin Weinberg Foundation". Archived from the original on 2016-03-05.

- ↑ SMITH, J; SIMMONS, W E (eds.). "AN ASSESSMENT OF A 2500 MEe MOLTEN CHLORIDE SALT FAST REACTOR" (PDF). UNITED KINGDOM ATOMIC ENERGY AUTHORITY Reactor Group. Retrieved 13 June 2015.

- ↑ May editor-first2=W E, W C; SIMMONS (eds.). "Conceptual Design and Assessment of a Helium-cooled 2500 MEe Molten Salt Reactor With Integrated Gas Turbine Plant" (PDF). UNITED KINGDOM ATOMIC ENERGY AUTHORITY Reactor Group. Retrieved 13 June 2015.

- ↑ The results of the investigations of Russian Research Center—‘‘Kurchatov Institute’’ on molten salt applications to problems of nuclear energy systems at AIP Conference Proceedings July 1994: v. 346, pp. 138–147

- ↑ Advanced Reactors with Innovative Fuels. 1 October 1999. ISBN 9789264171176.

- 1 2 Arkin, Fatima (2016-01-25). "An alternative fuel for nuclear energy looms". Retrieved 2016-07-15.

- ↑ Integral Molten Salt Reactor. terrestrialenergy.com

- ↑ "Pre-Licensing Vendor Design Review". Canadian Nuclear Safety Commission. Retrieved 10 November 2017.

- 1 2 Evans-Pritchard, Ambrose (6 January 2013) China blazes trail for 'clean' nuclear power from thorium The Daily Telegraph, UK. Accessed 18 March 2013

- ↑ Clark, Duncan (16 February 2011). "China enters race to develop nuclear energy from thorium". The Guardian.

- ↑ Halper, Mark. "China eyes thorium MSRs for industrial heat, hydrogen; revises timeline". Weinberg Next Nuclear. The Alvin Weinberg Foundation. Retrieved 9 June 2016.

- 1 2 3 Chen, Stephen (5 December 2017). "China Hopes Cold War Nuclear Energy Tech Will Power Warships, Drones". South China Morning Post. Retrieved 4 May 2018.

- ↑ "Research clarifies origin of superior properties of new materials for next-generation molten salt reactors - ANSTO". www.ansto.gov.au.

- ↑ "Molten salt reactor research develops class of alloys - World Nuclear News". world-nuclear-news.org.

- ↑ "Seaborg Wasteburner" (PDF).

- ↑ "European Commission : CORDIS : Projects & Results Service : Periodic Report Summary - EVOL (Evaluation and viability of liquid fuel fast reactor system)". Archived from the original on 2016-04-13.

- ↑ "EVOL (Project n°249696) FINAL REPORT" (PDF).

- ↑ Serp, Jérôme; Allibert, Michel; Beneš, Ondřej; Delpech, Sylvie; Feynberg, Olga; Ghetta, Véronique; Heuer, Daniel; Holcomb, David; Ignatiev, Victor (2014-11-01). "The molten salt reactor (MSR) in generation IV: Overview and perspectives". Progress in Nuclear Energy. 77: 308–319. doi:10.1016/j.pnucene.2014.02.014.

- ↑ "SAMOFAR home". SAMOFAR. Retrieved 2018-08-31.

- ↑ VIJAYAN, P K; BASAK, A; DULERA, I V; VAZE, K K; BASU, S; SINHA, R K (2015-08-28). "Conceptual design of Indian molten salt breeder reactor". Pramana. 85 (3): 539–554. doi:10.1007/s12043-015-1070-0. ISSN 0304-4289.

- ↑ "Indian Molten Salt Breeder Reactor (IMSBR) Initiated". Thorium Energy World. Retrieved 2018-08-31.

- ↑ Fuji Molten salt reactor. nextbigfuture.com. 19 December 2007

- 1 2 Barton, Charles (March 2008) Interview with Ralph Moir at Energy From Thorium blog

- ↑ Wang, Brian (2018-09-06). "Russian MBIR sodium cooled fast reactor on track to 2020 completion". NextBigFuture.com. Retrieved 2018-09-08.

- ↑ Clark, Duncan (9 September 2011). "Thorium advocates launch pressure group". The Guardian.

- ↑ "London: Weinberg Foundation to heat up campaign for safe, green,... – The Weinberg Foundation". Mynewsdesk.

- ↑ "New NGO to fuel interest in safe thorium nuclear reactors". businessgreen.com.

- ↑ Griffiths, Trevor; Tomlinson, Jasper; O’Sullivan, Rory. "MSR Review - Feasibility of Developing a Pilot Scale Molten Salt Reactor in the UK" (PDF). Energy Process Developments. Retrieved 14 January 2016.

- ↑ The Nuclear Institute UK (2017-06-20), Molten Salt Reactors - Dr Ian Scott, retrieved 2018-03-18

- ↑ Ehresman, Teri (ed.). Molten Salt Reactor (MSR) (PDF) (Fact Sheet). 08-GA50044-17-R1 R6-11. Idaho National Laboratory.

- 1 2 Kirk Sorensen has Started a Thorium Power Company at NextBigFuture blog, 23 May 2011

- ↑ "Flibe Energy". flibe-energy.com.

- ↑ "Live chat: nuclear thorium technologist Kirk Sorensen". The Guardian. 7 September 2011.

- ↑ "New Huntsville company to build thorium-based nuclear reactors". huntsvillenewswire.com.

- ↑ "A Pair of MIT Scientists Try to Transform Nuclear Power". Forbes. 27 September 2012.

- ↑ "New nuke could power world until 2083". The Register. 14 March 2013.

- ↑ Alspach, Kyle (2015-02-10). "MIT Startup Gets $2.5M to Develop the Nuclear Reactor We've Been Waiting For". BostInno Streetwise. Retrieved 2015-12-19.

- ↑ "Energy Department Announces New Investments in Advanced Nuclear Power Reactors..." US Department of Energy. Retrieved 16 January 2016.

- 1 2 3 Wang, Brian (2018-08-26). "Global race for transformative molten salt nuclear includes Bill Gates and China". NextBigFuture.com. Retrieved 2018-09-02.

- ↑ Gat, Uri; Engel, J. R.; Dodds, H. L. (28 February 1991), "The Molten Salt Reactor Option for Beneficial Use of Fissile Material from Dismantled Weapons", AAAS session on Fissile Materials from Nuclear Arms Reduction (PDF), Oak Ridge National Laboratory, TN

- ↑ Fluoride Salt-Cooled High-Temperature Reactor Workshop Announcement and Call for Participation, c. September 2010, at Oak Ridge National Laboratory, Oak Ridge Tennessee, USA. Accessed 18 March 2013

- ↑ Hargraves, Robert; Moir, Ralph (July 2010). "Liquid Fluoride Thorium Reactors". American Scientist. 98 (4): 304–313. doi:10.1511/2010.85.304.

- ↑ Van Gosen, B. S.; Armbrustmacher, T. J. (2009), Thorium deposits of the United States – Energy resources for the future?, Circular 1336, U.S. Geological Survey

- ↑ Greene, Sherrel (May 2011). Fluoride Salt-cooled High Temperature Reactors – Technology Status and Development Strategy. San Francisco, CA.

- ↑ Forsberg, Charles (November 2011) Fluoride-Salt-Cooled High-Temperature Reactors for Power and Process Heat. mit.edu

- ↑ Ingersoll, D. T. (December 2005). "ORNL/TM-2005/218, Status of Physics and Safety Analyses for the Liquid-Salt-Cooled Very High-Temperature Reactor (LS-VHTR)". ORNL. Retrieved 13 May 2010.

- ↑ Baron, Matthias; Böck, Helmuth; Villa, Mario. "TRIGA Reactor Characteristics". IAEA Education and Training. IAEA. Retrieved 2 June 2016.

- ↑ Gylfe, J.D. "US Patent 3,145,150, Aug. 18, 1954, Fuel Moderator Element for a Nuclear Reactor, and Method of Making". U.S. Patent Office. U.S. Government. Retrieved 2 June 2016.

- ↑ Massie, Mark; Dewan, Leslie C. "US 20130083878 A1, April 4, 2013, NUCLEAR REACTORS AND RELATED METHODS AND APPARATUS". U.S. Patent Office. U.S. Government. Retrieved 2 June 2016.

- 1 2 3 Shaffer, J. H. (January 1971), Preparation and Handling of Salt Mixtures for the Molten Salt Reactor Experiment (PDF), ORNL-4616, Oak Ridge National Laboratory

- ↑ Ignatiev, Victor (1 April 2010). Critical issues of nuclear energy systems employing molten salt fluorides (PDF). Lisbon, Portugal: ACSEPT.

- ↑ CForsberg, Charles (June 2004). "Safety and Licensing Aspects of the Molten Salt Reactor" (PDF). 2004 American Nuclear Society Annual Meeting. Pittsburgh, Pennsylvania: American Nuclear Society.

- 1 2 Andrews, Anthony (27 March 2008), "Nuclear Fuel Processing: U.S. Policy Development" (PDF), CRS Report for Congress, Congressional Research Service, RS22542

- ↑ Rosenthal, M.; Briggs, R.; Haubenreich, P., Molten-Salt Reactor Program: Semiannual Progress Report for Period Ending August 31, 1971 (PDF), ORNL-4728, Oak Ridge National Laboratory

- 1 2 J. R. Engel; et al. (1980). "Conceptual design characteristics of a denatured molten-salt reactor with once-through fueling" (PDF). ORNL/TM-7207. Oak Ridge National Lab, TN. Archived from the original (PDF) on 14 January 2010.

- ↑ LeBlanc, D. (2010) Denatured Molten Salt Reactors (DMSR): An Idea Whose Time Has Finally Come?. 31st Annual conference of the Canadian Nuclear Society & 34th CNS/CNA student conference, Vol. 2 of 2 ( 24–27 May 2010) Montreal, Quebec, Canada. ISBN 978-1-61782-363-3

- ↑ Plutonium(TRU) Transmutation and 233U Production by Single-Fluid Type Accelerator Molten-Salt Breeder (AMSB) Kazuo Furukawa, Yoshio Kato, Sergey E. Chigrinov, Int. Conf. Accelerator-driven Transmutation, Tech. Appl. (Las Vegas, 25–29 July 1994)

- ↑ Moir, M. W. (2002). "Cost of Electricity from Molten Salt Reactors (MSR)" (PDF). 138. Nuclear Technology: 93–95.

- ↑ US DOE Nuclear Energy Research Advisory Committee (2002). "A Technology Roadmap for Generation IV Nuclear Energy Systems" (PDF). GIF-002-00. Archived from the original (PDF) on 2007-11-29.

- ↑ Finnish research network for generation four nuclear energy systems. vtt.fi

- ↑ "Is the "Superfuel" Thorium Riskier Than We Thought?". Popular Mechanics. 5 December 2012.

- ↑ "Transatomic Power White Paper, v1.0.1, section 1.2" (PDF). Transatomic Power Inc. Archived from the original (PDF) on 5 July 2015. Retrieved 2 June 2016.

Further reading

- Energy from Thorium's Document Repository Contains scanned versions of many of the U.S. government engineering reports, over ten thousand pages of construction and operation experience. This repository is the main reference for the aircraft reactor experiment and molten-salt fueled reactor's technical discussion.

- Weinberg, Alvin M. (1994). The First Nuclear Era: The Life and Times of a Technological Fixer. Springer Science & Business Media. ISBN 978-1-56396-358-2.

- Bruce Hoglund's Eclectic Interests Home Page Nuclear Power, Thorium, Molten Salt reactors, etc.

- Generation IV International Forum MSR website

- INL MSR workshop summary

- "Molten Salt Chemistry Plays a Prominent Role in Accelerator-Driven Transmutation Systems". Archived from the original on 21 February 2013.

- Material Considerations for Molten Salt Accelerator-based Plutonium Conversion Systems J.H. Devan et al.

External links

| Wikimedia Commons has media related to Molten salt reactors. |

- International Thorium Energy Organisation – www.IThEO.org

- Idaho National Laboratory Molten Salt Reactor Fact Sheet

- Energy from Thorium Blog / Website

- Google TechTalks – Liquid Fluoride Thorium Reactor: What Fusion Wanted To Be by Dr. Joe Bonometti NASA / Naval Postgraduate School YouTube

- Pebble Bed Advanced High Temperature Reactor

- Thorium Remix LFTR in 5 Minutes and other LFTR Documentaries.

- Kun Chen from Chinese Academy of Sciences on China Thorium Molten Salt Reactor TMSR Program

- Review of Molten Salt Reactor Technology

- Molten Salt Reactors – Ralph Moir

- [1]

- Heuer, D.; Merle-Lucotte, E.; Allibert, M.; Brovchenko, M.; Ghetta, V.; Rubiolo, P. (2014-02-01). "Towards the thorium fuel cycle with molten salt fast reactors". Annals of Nuclear Energy. 64: 421–429. doi:10.1016/j.anucene.2013.08.002.

- ↑ "MSFR - Bibliography". Archived from the original on 16 November 2015.