Isopress AG

The Isopress AG (Isopress Ldt.) located at Birmensdorf, Zürich was one of the first Thermosetting polymer processors in Switzerland.

History

Isopress AG was founded 1940 and until 2015 ( to the end of Isopress AG) it was located at Stallikonerstrasse 69, in 8903 Birmensdorf, in a former spinning building of the textile industry.

Until its dend, Isopress produced a wide range of thermoplastic and thermoset components. In particular, components for railway technology (switch controllers, "chimney" lightning arrestors for the SBB-CFF-FFS Re 460 (for the company Société Anonyme of the Atelier de Sécheron), loudspeaker covers for S-Bahn wagons) as well as lift buttons, filters for medical technology, electrical components for the Schurter Holding (e.g. EMF switches) and knurled screws etc. The Isopress trained its own apprentices as plastic technologists, it also enabled plastic technologists apprentices of Lego Produktion AG Switzerland to study the second subject of thermosetting processing and to complete the occupational test in this field at the Isopress AG. In 2001, Isopress entered into a collaboration with Lanker AG in Oberriet. In 2015, Isopress AG was dissolved and integrated into Lanker AG.

Processing

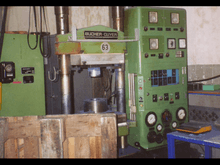

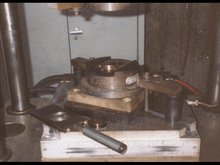

The products were produced in thermoset presses, with and without inserts, in injection molding (compression molding with a built-in injection plunger), in thermoset injection molding, thermoset injection molding and in thermoplastic injection molding. For this purpose, Sheet Molding CompoundWs were pressed in the thermosetting area as well as a kneading-type thermosetting resin with long glass fibers (with which the "lightning conductors" were manufactured for the Lok2000 underneath the other.) Taboucing presses were also used to pre-process thermosets for the Isopress as well as Lanker.

Thermoplastics: Isopress: Acrylonitrile-Butadiene-StyreneW, PolyoxymethyleneW, PolystyrolW, PolycarbonateW, PolyethylenW, PolypropyleneW (also with glass fibers). In the thermosetting range: phenol-formaldehyde resinW, melamine-formaldehyde resinW, urea-formaldehyde resin, unsaturated polyester resins, phenolic resins Pehnol resin, epoxy resinW. Some of these thermosetting resins had to be refrigerated .[1]

| Wikimedia Commons has media related to Isopress. |

References

- ↑ Datenblätter Isopress