Polyvinyl alcohol

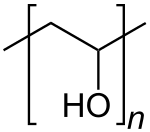

Poly(vinyl alcohol) (PVOH, PVA, or PVAl) is a water-soluble synthetic polymer. It has the idealized formula [CH2CH(OH)]n. It is used in papermaking, textiles, and a variety of coatings. It is colourless (white) and odorless. It is sometimes supplied as beads or as solutions in water.[3][4]

| |

| |

| Names | |

|---|---|

| Other names

PVOH; Poly(Ethenol), Ethenol, homopolymer; PVA; Polyviol; Vinol; Alvyl; Alcotex; Covol; Gelvatol; Lemol; Mowiol; Mowiflex, Alcotex, Elvanol, Gelvatol, Lemol, Mowiol, Nelfilcon A, Polyviol und Rhodoviol | |

| Identifiers | |

| ChEMBL | |

| ChemSpider |

|

| ECHA InfoCard | 100.121.648 |

| E number | E1203 (additional chemicals) |

| KEGG | |

| RTECS number |

|

CompTox Dashboard (EPA) |

|

| Properties | |

| (C2H4O)x | |

| Density | 1.19-1.31 g/cm3 |

| Melting point | 200 °C (392 °F; 473 K) |

| log P | 0.26 [1] |

Refractive index (nD) |

1.477 @ 632 nm[2] |

| Hazards | |

| Safety data sheet | External MSDS |

| NFPA 704 (fire diamond) | |

| Flash point | 79.44 °C (174.99 °F; 352.59 K) |

| Lethal dose or concentration (LD, LC): | |

LD50 (median dose) |

14,700 mg/kg (Mouse) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

Uses

PVA is used in a variety of medical applications because of its biocompatibility, low tendency for protein adhesion, and low toxicity. Specific uses include cartilage replacements, contact lenses, and eye drops.[5] Polyvinyl alcohol is used as an aid in suspension polymerizations. Its largest application in China is its use as a protective colloid to make polyvinyl acetate dispersions. In Japan its major use is the production of vinylon fiber.[6] Another application is photographic film.[7]

Medically, it may also used as the embolic agent in a Uterine Fibroid Embolectomy (UFE) [8]

Polyvinyl acetals

Polyvinyl acetals are prepared by treating PVA with aldehydes. Butyraldehyde and formaldehyde afford polyvinyl butyral (PVB) and polyvinyl formal (PVF), respectively. Preparation of polyvinyl butyral is the largest use for polyvinyl alcohol in the U.S. and Western Europe.

Unlike most vinyl polymers, PVA is not prepared by polymerization of the corresponding monomer as the monomer, vinyl alcohol, is less thermodynamically stable with respect to its tautomer acetaldehyde.

Preparation

PVA is prepared by hydrolysis of polyvinyl acetate.[3] Other vinyl ester-derived polymers are sometimes used, with formate, chloroacetate groups instead of acetate. The conversion of the polyesters is usually conducted by base-catalysed transesterification with ethanol:

- [CH2CH(OAc)]n + C2H5OH → [CH2CH(OH)]n + C2H5OAc

The properties of the polymer are affected by the degree of transesterification.

Worldwide consumption of polyvinyl alcohol was over one million metric tons in 2006.[6] Larger producers include Kuraray (Japan, Europe, and US) and Sekisui Specialty Chemicals (US) but mainland China has installed a number of very large production facilities in the past decade and currently accounts for 45% of world capacity. The North Korean-manufacture fiber Vinalon is produced from polyvinyl alcohol. Despite its inferior properties as a clothing fiber, it is produced for self-sufficiency reasons, because no oil is required to produce it.

Structure and properties

PVA is an atactic material that exhibits crystallinity. In terms of microstructure, it is composed mainly of 1,3-diol linkages [-CH2-CH(OH)-CH2-CH(OH)-] but a few percent of 1,2-diols [-CH2-CH(OH)-CH(OH)-CH2-] occur, depending on the conditions for the polymerization of the vinyl ester precursor.[3]

Polyvinyl alcohol has excellent film forming, emulsifying and adhesive properties. It is also resistant to oil, grease and solvents. It has high tensile strength and flexibility, as well as high oxygen and aroma barrier properties. However, these properties are dependent on humidity, in other words, with higher humidity more water is absorbed. The water, which acts as a plasticiser, will then reduce its tensile strength, but increase its elongation and tear strength.

Safety and environmental considerations

PVA is widely used, thus its toxicity and biodegradation are of interest. Solutions containing up to 5% PVA are nontoxic to fish.[3] It biodegrades slowly.[9]

References

- "Poly(vinyl alcohol)_msds".

- Schnepf, M.J.; Mayer, M.; Kuttner, C.; Tebbe, M.; Wolf, D.; Dulle, M.; Altantzis, T.; Formanek, P.; Förster, S.; Bals, S.; König, T.A.F.; Fery, A. (2017). "Nanorattles with tailored electric field enhancement". Nanoscale. 9 (27): 9376–9385. doi:10.1039/C7NR02952G. PMID 28656183.

- Hallensleben, Manfred L. (2000). "Polyvinyl Compounds, Others". Ullmann's Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:10.1002/14356007.a21_743.

- Tang, Xiaozhi; Alavi, Sajid (2011). "Recent Advances in Starch, Polyvinyl Alcohol Based Polymer Blends, Nanocomposites and Their Biodegradability". Carbohydrate Polymers. 85: 7–16. doi:10.1016/j.carbpol.2011.01.030.

- Baker, Maribel I.; Walsh, Steven P.; Schwartz, Zvi; Boyan, Barbara D. (2012). "A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications". Journal of Biomedical Materials Research Part B: Applied Biomaterials. 100B (5): 1451–1457. doi:10.1002/jbm.b.32694. PMID 22514196.

- SRI Consulting CEH Report Polyvinyl Alcohol, published March 2007, abstract retrieved July 30, 2008.

- Lampman, Steve (2003). Characterization and Failure Analysis of Plastics. ASM International. p. 29.

- https://emedicine.medscape.com/article/421734-overview#a4

- 10.1007/s00253-009-2113-6