Hallam Nuclear Generating Station

The Hallam Nuclear Power Facility (HNPF) in Nebraska was a 75 MWe graphite-moderated sodium-cooled nuclear power plant built by Atomics International.[1]

.jpg)

Full power was achieved in July 1963. The facility shut down on September 27, 1964 to resolve reactor problems. In May 1966, Consumers Public Power District rejected their option to purchase the facility from the Atomic Energy Commission (AEC). In response, the AEC announced its plan to decommission the facility in June, 1966. The facility operated for 6,271 hours and generated 192,458,000 kW-hrs of electric power.[2]

It was located near Hallam, about 25 miles southwest of Lincoln.

Description

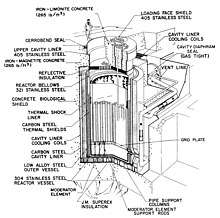

The graphite-moderated sodium-cooled reactor design was an attempt to achieve economical commercial nuclear electricity. The liquid metal coolant enabled high-temperature, low-pressure operation. The graphite moderator enabled operation with low-enriched nuclear fuel. The benefits of this combination were expected to overcome the added complication of a chemically reactive coolant.[3]

The reactor was initially fueled with 3.6% enriched uranium-10 molybdenum alloy with stainless steel fuel. The graphite moderator was also clad in stainless steel. Three sodium heat-transfer loops (each with a radioactive primary loop and a non-radioactive secondary) moved heat to three steam generators. Steam fed into a common header to a single turbine-generator. The primary hot leg temperature was 945 °F and the secondary hot leg temperature was 895 °F.

Uranium carbide was selected for the second core, at 4.9% enrichment.

Proposal, Development, and Construction

Hallam was proposed in March 1955 in response to the first round of invitations by the Atomic Energy Commission's Power Demonstration Reactor Program.[5] It used technology being developed in the smaller Sodium Reactor Experiment (SRE), also built by Atomics International. Lessons from SRE applied to HNPF include:

- Fuel rod blowing

- Poor control of sodium convection flow

- Stratification of sodium in intermediate heat exchanger

- Difficulties due to freeze-seal sodium pumps

- Difficulties in preheating of sodium systems

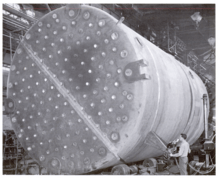

Because HNPF was more than ten times larger than SRE, a components development and test program was performed to provide final design data. All major components, including fuel, control rods, instrumentation, pumps, and valves were tested. The fuel handling machine was assembled and tested. Scale model of a steam generator was tested in a sodium loop along related equipment and instrumentation[2].

A formal three-session training program for operators was conducted in 1960. 30 personnel attended the first session for six months. Each person received approximately 900 hours of training.

Construction began on April 1, 1959. Employment during construction peaked at 270 in March, 1961, and 107,600 person-days total were required to complete the construction. A variety of construction assembly interferences were anticipated, and detailed scale models were procured. Labor problems resulted in the loss of 1750 person-days. The entire facility was completed on November 30, 1961, 4 months past the original planned date of completion[2].

Operation and shutdown

Initial criticality was achieved in January 1962, followed by wet criticality six months later. Difficulties that arose during operation and required plant shutdown and correction included leaking control rod thimbles, seizure of secondary sodium pumps, leaking steam generator instrumentation and pipe flanges, difficulty of adjusting fuel channel flow orifices, and failure of primary and secondary sodium throttle valves.

The most serious issue was the ruptures of moderator elements. Three elements ruptures in February, 1964. The ruptures and subsequent absorption of sodium into the graphite reduced the thermal neutron flux in the core and therefore a reduction in local power. The moderator elements swelled as well, reducing coolant and process space. Examination disclosed that failure was caused by low ductility stress-rupture leading to a one inch long crack about three inches below the top of each element.

Because the cost of correcting the failure would have outweighed the benefits, the plant was instead decommissioned and the nuclear components sealed in concrete.

The plant's single 75 MWe reactor operated from 1963 to September 27, 1964.[2] Decommissioning was completed in 1969.[6]

- Present day

Currently the site holds a fossil-fuel plant, Sheldon Power Station. The site is monitored from 17 monitoring wells and no radioactivity above background levels in any samples has been detected.[7]

References

- "IAEA - Reactor Details - Hallam". IAEA. 2013-04-13. Retrieved 2013-04-14.

- Burton, S.F.; Holser, A.G. (1966-10-01). Small nuclear power plants (Vol 1 ed.). US Atomic Energy Commission. p. 140. Retrieved 31 December 2019.

- Starr, Chauncey; Dickinson, Robert (1958). Sodium graphite reactors. Addison-Wesley Pub. Co. hdl:2027/mdp.39015003993881.

- Mahlmeister, J.E. (1961-12-01). "Engineering and constructing the Hallam Nuclear Power Facility reactor structure". Atomics International. Retrieved 31 December 2019.

- Atomic Energy Commission (1963-10-15). "Cooperative Power Reactor Demonstration Program". Hearings Before the United States Joint Committee on Atomic Energy, Subcommittee on Legislation, Eighty-Eighth Congress: 227. Retrieved 31 December 2019.

- State's First Nuclear Power Plant

- "Hallam, Nebraska, Decommissioned Reactor Site Fact Sheet" (PDF). US DOE Office of Legacy Management. Retrieved 31 December 2019.