Split pin

.png)

A split pin, also known in the United States as a cotter pin or cotter key,[1] is a metal fastener with two tines that are bent during installation, similar to a staple or rivet. Typically made of thick wire with a half-circular cross section, split pins come in multiple sizes and types.

The British definition of "cotter pin" is equivalent to U.S. term "cotter". To avoid confusion the term split cotter is sometimes used for a split pin. A further use of the term "cotter pin" is the "crank cotter pin" used to lock bicycle pedal cranks to the bottom bracket axle. These are not "split" at all and are wedge shaped.

Construction

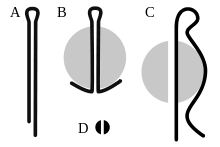

A new split pin (see figure A) has its flat inner surfaces touching for most of its length so that it appears to be a split cylinder (figure D). Once inserted, the two ends of the pin are bent apart, locking it in place (figure B). When they are removed they are supposed to be discarded and replaced, because of fatigue from bending.[2]

Split pins are typically made of soft metal, making them easy to install and remove, but also making it inadvisable to use them to resist strong shear forces. Common materials include mild steel, brass, bronze, stainless steel, and aluminium.[3]

Types

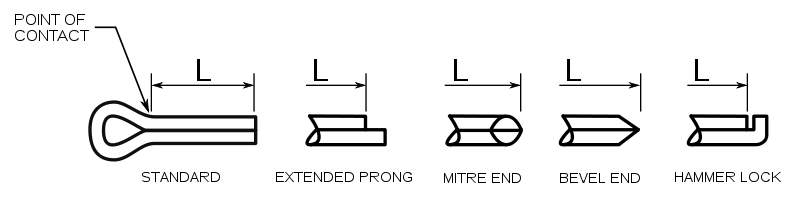

As shown above, there are different types of ends available on split pins. The most common is the extended prong with a square cut, but extended prongs are available with all of the other types of ends. The extended prong type is popular because it makes it easier to separate the tines. To ease insertion into a hole the longer tine may be slightly curved to overlap the tip of the shorter tine or it is beveled. The length, L, of the split pin is defined as the distance from the end of the shortest tine to the point of the eyelet that contacts the hole.[3]

Hammer lock split pins are properly installed by striking the head with a hammer to secure the pin. This forces the shorter tine forward, spreading the pin.[4]

- Standard

- Humped

- Clinch

Sizes

The diameter of split pins are standardized. American split pins start at 1⁄32 in and end at 3⁄4 in.[4]

| Nominal diameter [mm] | Hole size [mm] | For bolt size [mm] |

|---|---|---|

| 1.5 | 1.9 | 6 |

| 2 | 2.4 | 8 |

| 2.5 | 2.8 | 10 |

| 3 | 3.4 | 12, 14 |

| 4 | 4.5 | 20 |

| 5 | 5.6 | 24, 28 |

| 6 | 6.3 | 30, 36, 42 |

| 8 | 8.5 | 48 |

| Nominal diameter [in] | Hole size [in] | For bolt size [in] |

|---|---|---|

| 1⁄32 | 3⁄64 | |

| 3⁄64 | 1⁄16 | |

| 1⁄16 | 5⁄64 | 1⁄4 |

| 5⁄64 | 3⁄32 | 5⁄16 |

| 3⁄32 | 7⁄64 | 3⁄8 |

| 7⁄64 | 1⁄8 | |

| 1⁄8 | 9⁄64 | 1⁄2 |

| 9⁄64 | 5⁄32 | 5⁄8 |

| 5⁄32 | 11⁄64 | 3⁄4 |

| 3⁄16 | 13⁄64 | 1, 1.125 |

| 7⁄32 | 15⁄64 | 1.25, 1.375 |

| 1⁄4 | 17⁄64 | 1.5 |

| 5⁄16 | 5⁄16 | 1.75 |

| 3⁄8 | 3⁄8 | |

| 7⁄16 | 7⁄16 | |

| 1⁄2 | 1⁄2 | |

| 5⁄8 | 5⁄8 | |

| 3⁄4 | 3⁄4 |

Applications

Split pins are frequently used to secure other fasteners, e.g. clevis pins, as well as being used in combination with hardboard discs as a traditional joining technique for teddy bears.[6] A common application of this is when used to secure a castellated nut. [7]

Split pins may be used in some applications as low-tech shear pins.

See also

- Bowtie cotter pin

- Circle cotter

- Hairpin clip

- Linchpin

- R-clip

- Spring pin

References

- ↑ U.S. Patent 4,298,299

- ↑ Welsch 2005, p. 141.

- 1 2 Soled 1957, p. 312.

- 1 2 3 Cotter pins, retrieved 2009-08-17 .

- 1 2 Jensen 2001, p. 234.

- ↑ Baby Pip Teddy Bear at CraftBits.com

- ↑ Reithmaier 1999, p. 151.

Bibliography

- Jensen, Cecil Howard (2001), Interpreting Engineering Drawings (6th ed.), SteinerBooks, ISBN 978-0-7668-2897-1 .

- Reithmaier, Lawrence W. (1999), Standard aircraft handbook for mechanics and technicians (6th ed.), McGraw-Hill Professional, ISBN 978-0-07-134836-2 .

- Soled, Julius (1957), Fasteners handbooks, Reinhold Publication Corporation .

- Welsch, Roger (2005), From Tinkering to Torquing: A Beginner's Guide to Tractors and Tools, MBI Publishing Company, ISBN 978-0-7603-2082-2 .

| Wikimedia Commons has media related to Split cotter pins. |