Split-phase electric power

A split-phase or single-phase three-wire system is a type of single-phase electric power distribution. It is the AC equivalent of the original Edison three-wire direct-current system. Its primary advantage is that it saves conductor material over a single-ended single-phase system, while only requiring a single phase on the supply side of the distribution transformer.[1]

The two 120 V AC "Lines" are supplied to the premises from a transformer with a 240 V AC "secondary" winding which has a “Center Tap” connected to Ground – with the Ground being "Neutral". This results in two 120 V AC “Line” voltages which are “out of phase” by 180 degrees with each other.

(While the RMS value of each Line voltage [with respect to the Grounded “center tapped” Neutral] is 120 V, the Peak sine wave voltage of each is 170 V, with respect to the grounded Neutral.)

When required, 240 V AC can be obtained by connecting the Load concerned between the two 180 degree “out of phase” 120 V AC "Lines".

Connections

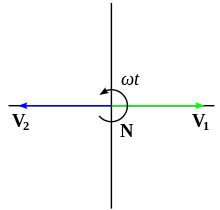

A transformer supplying a three-wire distribution system has a single-phase input (primary) winding. The output (secondary) winding is center-tapped and the center tap connected to a grounded neutral. As shown in Fig. 1. either end to center has half the voltage of end-to-end. Fig. 2 illustrates the phasor diagram of the output voltages for a split-phase transformer. Since the two phasors do not define a unique direction of rotation for a revolving magnetic field, a split single-phase is not a two-phase system.

In the United States and Canada, the practice originated with the DC distribution system developed by Thomas Edison. By connecting pairs of lamps or groups of lamps on the same circuit in series, and doubling the supply voltage, the size of conductors was reduced substantially.

The line to neutral voltage is half the line-to-line voltage. Lighting and small appliances requiring less than 1800 Watts may be connected between a line wire and the neutral of the basic North American domestic 15 A circuit - although 20 A circuits supplying up to 2400 W may be provided. Higher wattage appliances, such as cooking equipment, space heating, water pumps, clothes dryers, and air conditioners are connected across the two line conductors. This means that (for the supply of the same amount of energy) the current is halved. Hence, smaller conductors may be used than would be needed if the appliances were designed to be supplied by the lower voltage. [2]

If the load were guaranteed to be balanced, then the neutral conductor would not carry any current and the system would be equivalent to a single-ended system of twice the voltage with the line wires taking half the current. This would not need a neutral conductor at all, but would be wildly impractical for varying loads; just connecting the groups in series would result in excessive voltage and brightness variation as lamps are switched on and off.

By connecting the two lamp groups to a neutral, intermediate in potential between the two live legs, any imbalance of the load will be supplied by a current in the neutral, giving substantially constant voltage across both groups. The total current carried in all three wires (including the neutral) will always be twice the supply current of the most heavily loaded half.

For short wiring runs limited by conductor ampacity, this allows three half-sized conductors to be substituted for two full-sized ones, using 75% of the copper of an equivalent single-phase system.

Longer wiring runs are more limited by voltage drop in the conductors. Because the supply voltage is doubled, a balanced load can tolerate double the voltage drop, allowing quarter-sized conductors to be used; this uses 3/8 the copper of an equivalent single-phase system.

In practice, some intermediate value is chosen. For example, if the imbalance is limited to 25% of the total load (half of one half) rather than the absolute worst-case 50%, then conductors 3/8 of the single-phase size will guarantee the same maximum voltage drop, totalling 9/8 of one single-phase conductor, 56% of the copper of the two single-phase conductors.

Balanced power

In a so-called balanced power system, an isolation transformer with a center tap is used to create a separate supply with conductors at a balanced Vnom/2 with respect to ground. The purpose of a balanced power system is to minimize the noise coupled into sensitive equipment from the power supply.

Unlike a three-wire distribution system, the grounded neutral is not distributed to the loads; only line-to-line connections at 120 V are used. A balanced power system is only used for specialized distribution in audio and video production studios, sound and television broadcasting, and installations of sensitive scientific instruments.

The U.S. National Electrical Code provides rules for technical power installations.[3] The systems are not to be used for general-purpose lighting or other equipment, and may use special sockets to ensure only approved equipment is connected to the system. Additionally, technical power systems pay special attention to the way the distribution system is grounded.

A risk of using a balanced power system, in an installation that also uses "conventional" power in the same rooms, is that a user may inadvertently interconnect the power systems together via an intermediate system of audio or video equipment, elements of which might be connected to different power systems.

Applications

Europe

In Europe, three-phase 230/400 V is most commonly used. However, 230/460 V, three-wire, single-phase systems are used to run farms and small groups of houses when only one (or sometimes two) of the three-phase high-voltage conductors is available. A split-phase final step-down transformer is often used, with the centre-tap earthed and the two halves usually supplying different buildings.

In the UK, electric tools and portable lighting at construction sites are required to be fed from a centre-tapped system with only 55 V between live conductors and the earth. This system is used with 110 V equipment and therefore no neutral conductor is needed. The intention is to reduce the electrocution hazard that may exist when using electrical equipment at a wet or outdoor construction site. Portable transformers that transform single-phase 240 V to this 110 V system are a common piece of construction equipment. Generator sets used for construction sites are equipped to supply it directly.

An incidental benefit is that the filaments of 110 V incandescent lamps used on such systems are thicker and therefore mechanically more rugged than those of 240 V lamps.

Oceania

In Australia, New Zealand and many Asian countries, remote loads in rural areas may be connected to the grid using SWER (single-wire earth return) transmission lines, since it is cheaper to run only one High Voltage conductor. The primary of the transformer concerned is connected between the high voltage Line and Earth, with the secondary being a “standard” 230 V single phase supply, with the Neutral connected to the same Earth connection. (This is quite unlike the "Split-phase" supply described in this article.)

North America

This three-wire single phase system is common in North America for residential and light commercial applications. Breaker panels typically have a two hot wires, a neutral (connected at the other end to the grounded center tap of a local transformer), and a ground wire feeding in from the local distribution grid. Circuit breakers then either create 120 V circuits by connecting one hot to neutral through a load, or 240 V circuits by connecting the two hot wires through a load. 120 V circuits are the most common, and used to power NEMA 1 and NEMA 5 outlets, and direct-wired lights and appliances. 240 V circuits are used only for high-demand applications, typically electric stoves, electric clothes dryers, and electric cars, and some space heaters, air conditioners, and water heaters. These use NEMA 10 or NEMA 14 outlets that are deliberately incompatible with the 120 V outlets.

Wiring regulations govern the application of split-phase circuits; since the neutral (return) conductor is not protected by a fuse or circuit breaker, a neutral wire can be shared only by circuits fed from opposite lines of the supply system. Two circuits from opposing lines may share a neutral if both breakers are connected by a bar so that both trip simultaneously ([4]NEC 210.4), this prevents 120 V from feeding across 240 V circuits.

Some buildings have 208 V three-phase power instead of split-phase, for high-capacity circuits.

Railways

In Sweden split-phase electric power is also used on some railways. The center tap is grounded, one pole is fed with an overhead wire section, while the other wire is used for another section.

Amtrak's 60 Hz traction power system in the Northeast Corridor between New York and Boston also uses split-phase power distribution. Two separate wires are run along the track, the contact wire for the locomotive and an electrically separate feeder wire. Each wire is fed with 25 kV with respect to ground, with 50 kV between them. Autotransformers along the track balance the loads between the contact and feeder wires, reducing resistive losses.

In the UK Network Rail are using autotransformers on all new 50 Hz electrification, and (as of 2014) are converting many old booster transformer installations to autotransformers, to reduce energy losses and exported electromagnetic interference, both of which increase when longer, heavier, or faster trains are introduced, drawing higher peak current from the supply. Note that booster transformers only "boost" the return of traction current through its intended path, the "return conductor", rather than randomly through the earth, and do not boost, but rather reduce, the available voltage at the train, and introduce additional losses. The autotransformer system enforces the traction return current taking its intended path, while reducing the transmission losses, and therefore achieves both required objectives, of controlling return current leakage to earth and ensuring low energy loss, simultaneously. There is an initial cost penalty, because the previous return conductor, insulated to a fairly modest voltage, must be replaced by an anti-phase feeder, insulated to 25 kV, and the autotransformers themselves are larger and more expensive than the previous booster transformers.

See also

References

- ↑ Terrell Croft and Wilford Summers (ed), American Electricians' Handbook, Eleventh Edition, McGraw Hill, New York (1987) ISBN 0-07-013932-6, chapter 3, pages 3-10, 3-14 to 3-22.

- ↑ Gonen, Turan. Electric Power Distribution System Engineering, 2nd ed. CRC Press, 2007, p. 284.

- ↑ NFPA 70, National Electrical Code 2005, National Fire Protection Association, Inc., Quincy, Massachusetts USA, (2005). no ISBN , articles 640 and 647

- ↑ http://ecmweb.com/code-basics/branch-circuits-part-1