Radiant cooling

Radiant cooling is the use of cooled surfaces to remove sensible heat by radiation and convection. It is related to radiant heating. Radiant systems that use water to cool the radiant surfaces are called hydronic systems. Unlike “all-air” air conditioning systems that circulate cooled air only, hydronic radiant systems circulate cooled water in pipes through specially-mounted panels or a building’s floor or ceiling to provide comfortable temperatures. There is a separate system to provide air for ventilation, dehumidification, and potentially additionally cooling.[1] Radiant systems are less common than all-air systems for cooling, but can have advantages compared to all-air systems in some applications.[2][3][4]

Some well-known buildings using radiant cooling include Bangkok’s Suvarnabhumi Airport,[5] the Infosys Software Development Building 1 in Hyderabad, IIT Hyderabad,[6] and the San Francisco Exploratorium.[7] Radiant cooling is also used as a design strategy in some net zero energy buildings.[8][9]

Background

Definition

By definition, radiant cooling systems primarily remove sensible heat through thermal radiation. ASHRAE defines radiant systems as temperature-controlled surfaces where 50% or more of the design heat transfer takes place by thermal radiation.[1]

Physics

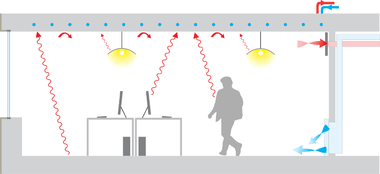

Thermal (longwave) radiation travels at the speed of light, in straight lines.[1] It can be reflected. People, equipment, and surfaces in buildings will warm up if they absorb thermal radiation, but the radiation does not noticeably heat up the air it is traveling through.[1] This means heat will flow from objects, occupants, equipment, and lights in a space to a cooled surface as long as their temperatures are warmer than that of the cooled surface and they are within the direct or indirect line of sight of the cooled surface. Some heat is also removed by convection because the air temperature will be lowered when air comes in contact with the cooled surface.

History

Radiant heating systems have been used for thousands of years, notably in ancient Korea, China, and Rome.[10] Hydronic radiant cooling systems are relatively more recent. Early radiant cooling systems were installed in the late 1930s and 40's in Europe[11] and by the 1950s in the US.[12] They became more common in Europe in the 1990s and continue to be used today.[13]

System design

Radiant cooling systems are usually hydronic, cooling using circulating water running in pipes in thermal contact with the surface. Typically the circulating water only needs to be 2–4 °C below the desired indoor air temperature.[14] Once having been absorbed by the actively cooled surface, heat is removed by water flowing through a hydronic circuit, replacing the warmed water with cooler water.

Since the majority of the cooling process results from removing sensible heat through radiant exchange with people and objects and not air, occupant thermal comfort can be achieved with warmer interior air temperatures than with air based cooling systems. As a result of the high cooling capacity of water, and the delivery of a cooled surface close to the desired indoor air temperature, radiant cooling systems potentially offer reductions in cooling energy consumption.[2] The latent loads (humidity) from occupants, infiltration and processes generally need to be managed by an independent system. Radiant cooling may also be integrated with other energy-efficient strategies such as night time flushing, indirect evaporative cooling, or ground source heat pumps as it requires a small difference in temperature between desired indoor air temperature and the cooled surface.[14]

System types

While there are a broad range of system technologies, there are two primary types of radiant cooling systems. The first type is systems that deliver cooling through the building structure, usually slabs. These systems are also named thermally activated building systems (TABS).[15] The second type is systems that deliver cooling through specialized panels. Systems using concrete slabs are generally cheaper than panel systems and offer the advantage of thermal mass, while panel systems offer faster temperature control and flexibility.

Chilled slabs

Radiant cooling from a slab can be delivered to a space from the floor or ceiling. Since radiant heating systems tend to be in the floor, the obvious choice would be to use the same circulation system for cooled water. While this makes sense in some cases, delivering cooling from the ceiling has several advantages.

First, it is easier to leave ceilings exposed to a room than floors, increasing the effectiveness of thermal mass. Floors offer the downside of coverings and furnishings that decrease the effectiveness of the system.

Second, greater convective heat exchange occurs through a chilled ceiling as warm air rises, leading to more air coming in contact with the cooled surface.

Cooling delivered through the floor makes the most sense when there is a high amount of solar gain from sun penetration, because the cool floor can more easily remove those loads than the ceiling.[14]

Chilled slabs, compared to panels, offer more significant thermal mass and therefore can take better advantage of outside diurnal temperatures swings. Chilled slabs cost less per unit of surface area, and are more integrated with structure.

Ceiling panels

Radiant cooling panels are generally attached to ceilings, but can be attached to walls also. They are usually suspended from the ceiling, but can also be directly integrated with continuous dropped ceilings. Modular construction offers increased flexibility in terms of placement and integration with lighting or other electrical systems. Lower thermal mass compared to chilled slabs means they can’t easily take advantage of passive cooling from thermal storage, but controls in panels can more quickly adjust to changes in outdoor temperature. Chilled panels are also better suited to buildings with spaces that have a greater variance in cooling loads.[1] Perforated panels also offer better acoustical dampening than chilled slabs. Ceiling panels are also very suitable for retrofits because they can be attached to any ceiling. Chilled ceiling panels can be more easily integrated with ventilation supplied from the ceiling. Panels tend to cost more per unit of surface area than chilled slabs.

Advantages

Radiant cooling systems offer lower energy consumption than conventional cooling systems based on research conducted by the Lawrence Berkeley National Laboratory. Radiant cooling energy savings depend on the climate, but on average across the US savings are in the range of 30% compared to conventional systems. Cool, humid regions might have savings of 17% while hot, arid regions have savings of 42%.[2] Hot, dry climates offer the greatest advantage for radiant cooling as they have the largest proportion of cooling by way of removing sensible heat. While this research is informative, more research needs to be done to account for the limitations of simulation tools and integrated system approaches. Much of the energy savings is also attributed to the lower amount of energy required to pump water as opposed to distribute air with fans. By coupling the system with building mass, radiant cooling can shift some cooling to off-peak night time hours. Radiant cooling appears to have lower first costs [16] and lifecycle costs compared to conventional systems. Lower first costs are largely attributed to integration with structure and design elements, while lower life cycle costs result from decreased maintenance. However, a recent study on comparison of VAV reheat versus active chilled beams & DOAS challenged the claims of lower first cost due to added cost of piping [17]

Limiting factors

Because of the potential for condensate formation on the cold radiant surface (resulting in water damage, mold and the like), radiant cooling systems have not been widely applied. Condensation caused by humidity is a limiting factor for the cooling capacity of a radiant cooling system. The surface temperature should not be equal or below the dew point temperature in the space. Some standards suggest a limit for the relative humidity in a space to 60% or 70%. An air temperature of 26 °C (79 °F) would mean a dew point between 17 °C and 20 °C (63 °F and 68 °F).[14] There is, however, evidence that suggests decreasing the surface temperature to below the dew point temperature for a short period of time may not cause condensation.[16] Also, the use of an additional system, such as a dehumidifier or DOAS, can limit humidity and allow for increased cooling capacity.

References

- 1 2 3 4 5 ASHRAE Handbook. HVAC Systems and Equipment. Chapter 6. Panel Heating and Cooling Design. ASHRAE. 2016.

- 1 2 3 Stetiu, Corina (June 1999). "Energy and peak power savings potential of radiant cooling systems in US commercial buildings". Energy and Buildings. 30 (2): 127–138. doi:10.1016/S0378-7788(98)00080-2.

- ↑ Higgins C, Carbonnier K (June 2017). Energy Performance of Commercial Buildings with Radiant Heating and Cooling (Report). pp. 9–12. Retrieved November 8, 2017.

- ↑ Karmann, Caroline; Schiavon, Stefano; Bauman, Fred (January 2017). "Thermal comfort in buildings using radiant vs. all-air systems: A critical literature review". Building and Environment. 111: 123–131. doi:10.1016/j.buildenv.2016.10.020.

- ↑ Simmonds, P.; Holst, S.; Reuss, S.; Gaw, W. (1 June 2000). "Using Radiant Cooled Floors to Condition Large Spaces and Maintain Comfort Conditions". ASHRAE Transactions: Symposia. ASHRAE Winter Meeting. Dallas, TX (US): American Society of Heating, Refrigerating and Air-Conditioning Engineers. pp. 695–701. OSTI 20104826.

- ↑ Sastry, Guruprakash; Rumsey, Peter (May 2014). "VAV vs. Radiant - side by side comparison". ASHRAE Journal. Atlanta, GA (USA): ASHRAE. Archived from the original on 9 November 2017. Retrieved 8 November 2017.

- ↑ Wenisch, Joseph; Gaunt, Lindsey (Spring 2015). "Inspiring explorers - Case study: The Exploratorium" (PDF). High Performing Buildings. Atlanta, GA (USA): ASHRAE. eISSN 1940-3054. Retrieved 8 November 2017.

- ↑ 2016 List of Zero Net Energy Buildings (Report). New Buildings Institute. 13 October 2016. p. 8. Retrieved 8 November 2017.

- ↑ Maor, Itzhak; Snyder, Steven C. (Fall 2016). "Evaluation of Factors Impacting EUI from High Performing Building Case Studies". High Performing Buildings. Atlanta, GA (USA): ASHRAE. eISSN 1940-3054. Retrieved 8 November 2017.

- ↑ Bean, Robert; Olesen, Bjarne; Kim, Kwang Woo (February 2010). "History of Radiant Heating and Cooling Systems – Part 2" (PDF). ASHRAE Journal. Atlanta, GA (USA): ASHRAE. Retrieved 8 November 2017.

- ↑ Giesecke, Frederick E. (1947). "Chapter 24 - Radiant cooling". Hot-water heating and radiant heating and radiant cooling. Austin, Texas: Technical Book Company.

24-6. The first large building in Zurich equipped with a combination radiant heating and cooling system is the department store Jelmoli (Fig 24-1). The first sections of this store were erected during the period from 1899 to 1932 and equipped with a standard radiator-heating system using low-pressure steam; the latest section was erected in 1933-37 and equipped with a combination radiant heating and cooling system...The Administration Building of Saurer Co. in Arbon and the Municipal Hospital in Basel are among the more important buildings recently equipped with radiant cooling systems.

- ↑ Manley, John K., ed. (1954). "Radiant cooling and air conditioning". Radiant Heating, Radiant Cooling. Bulletin No. 1. Pratt Institute School of Architecture. pp. 24–25. OCLC 11520430.

This type of system has proved successful in several installations. It was first attempted in a few sample rooms in Radio City about five years ago. Since that time, it has appeared in the 30-story Alcoa Building as well as in another multi-story building in Canada. Both of the latter structures are heated in winter and cooled in summer by the same coils of pipe in metal ceilings.

- ↑ Olesen, Bjarne W. (February 2012). "Thermo Active Building Systems Using Building Mass to Heat and Cool" (PDF). ASHRAE Journal. Vol. 54 no. 2. Atlanta, GA (USA): ASHRAE. Retrieved 20 November 2017.

- 1 2 3 4 Olesen, Bjarne W. (September 2008). "Hydronic Floor Cooling Systems". ASHRAE Journal.

- ↑ Gwerder, M.; B. Lehmann; J. Tödtli; V. Dorer; F. Renggli (July 2008). "Control of thermally-activated building systems (TABS)". Applied Energy. 85 (7): 565–581. doi:10.1016/j.apenergy.2007.08.001.

- 1 2 Mumma, S.A. (2002). "Chilled ceilings in parallel with dedicated outdoor air systems: Addressing the concerns of condensation, capacity, and cost". ASHRAE Transactions. 108 (2): 220–231.

- ↑ Stein, Jeff; Steven T. Taylor (2013). "VAV Reheat Versus Active Chilled Beams & DOAS". ASHRAE Journal. 55 (5): 18–32.

Further reading

ASHRAE Handbook. HVAC Systems and Equipment 2012. Chapter 13. Hydronic Heating and Cooling.

ASHRAE Handbook. HVAC Systems and Equipment 2008. Chapter 12. Hydronic Heating and Cooling System Design.

Kessling, W., Holst, S., Schuler, M. Innovative Design Concept for the New Bangkok International Airport, NBIA.

Olesen, B.W. Radiant Heating and Cooling by Water-based systems. Technical University of Denmark, International Centre for Indoor Environment and Energy.