Pratt & Whitney JT9D

| JT9D | |

|---|---|

| |

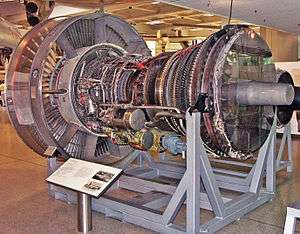

| The internal structure of the JT9D | |

| Type | Turbofan |

| National origin | United States |

| Manufacturer | Pratt & Whitney |

| First run | December 1966 |

| Major applications | Airbus A300 Airbus A310 Boeing 747-100 Boeing 747-200 Boeing 747SP Boeing 747-300 Boeing 767 McDonnell Douglas DC-10 |

| Produced | 1966-1990 |

| Developed into | Pratt & Whitney PW4000 |

The Pratt & Whitney JT9D engine was the first high bypass ratio jet engine to power a wide-body airliner. Its initial application was the Boeing 747-100, the original "Jumbo Jet". It was Pratt & Whitney's first high-bypass-ratio turbofan.[1]

Design and development

The JT9D was built using titanium alloys and nickel alloys. The engine featured a single-stage fan, a three-stage low-pressure compressor and an eleven-stage high-pressure compressor coupled to a two-stage high-pressure turbine and four-stage low-pressure turbine. The JT9D-3, the earliest certified version of the engine, weighed 8,608 lb (3,905 kg) and produced 43,500 lbf (193,000 N) thrust. The original cost of the engine was $800,000 in 1968 ($5.6 million adjusted to 2017).[2] Production ceased in 1990 in favor of the newer PW4000 engines which are less complex, more reliable, and cost less to purchase.

The JT9D was developed starting in September 1965 as part of the design of the C-5 Galaxy. A contract was awarded to Pratt & Whitney to study the type of large engine needed, but the production contract was eventually awarded to General Electric and their TF39 turbofan. The JT9D was, however, chosen by Boeing to power the 747. The engine's first test run took place in a test rig in December 1966 at East Hartford, Connecticut, with the engine's first flight in June 1968 mounted on a Boeing B-52E which served as a 747 testbed.

Pratt & Whitney faced enormous difficulties with the JT9D design during the Boeing 747 test program. Engine failures during the flight test program resulted in thirty aircraft being parked outside the factory with concrete blocks hanging from the pylons, awaiting redesigned engines.

Boeing and Pratt & Whitney worked together in 1969 to solve the problem. The trouble was traced to ovalization, in which stresses during takeoff caused the engine casing to deform into an oval shape and cause the high-pressure turbine blades to grind against the sides. This was solved by strengthening the engine casing and adding yoke-shaped thrust links.

JT9D engines powering USAF E-4A airborne command posts were designated F105.

Variants

- JT9D-1

- development engines - 42,000 lbf (186.83 kN)

- JT9D-3

- the earliest certified version of the engine, weighed 8,608 lb (3,905 kg) and produced 43,500 lbf (193.50 kN)

- JT9D-7

- 46,300 to 50,000 lbf (205.95 to 222.41 kN)

- F105

- Military designation for JT9D engines fitted to Boeing 747 derivatives in service with the United States Air force (USAF).

Applications

Specifications (JT9D-7 series)

Data from [3]

General characteristics

- Type: High bypass two-spool turbofan engine

- Length: 128.2 in (3,260 mm) (less intake ring and nozzle)

- Diameter: 92.3 in (2,340 mm) (Fan tip)

- Dry weight: 8,608 lb (3,905 kg)

Components

- Compressor: 1-stage Fan, 3-stage LP compressor and 11-stage HP compressor

- Combustors: Annular combustion chamber

- Turbine: 2-stage HP turbine and 4-stage LP turbine

- Fuel type: Aviation Kerosene typically Jet A-1

- Oil system: pressure spray with scavenge

Performance

- Maximum thrust: 46,300 to 50,000 lbf (205.95 to 222.41 kN) take-off

- Overall pressure ratio: overall 23.4:1 (Fan 1.64:1)

- Bypass ratio: 5.0:1

- Specific fuel consumption: ca 0.6 lb/lbf/hr (61.16 kg/kN/hr) at M0.8 at 35,000 ft (11,000 m)[4]

- Thrust-to-weight ratio: 5.4 to 5.8

| Model | Static Thrust | Basic Engine Weight | Length | Fan Diameter | Application |

|---|---|---|---|---|---|

| JT9D-3A | 45,800 lbf (203.73 kN) | 8,608 lb (3,905 kg) | 128.2 in (3,260 mm) | 92.3 in (2,340 mm) | Boeing 747-100 |

| JT9D-7 | 47,900 lbf (213.07 kN) | 8,850 lb (4,010 kg) | 128.2 in (3,260 mm) | 92.3 in (2,340 mm) | Boeing 747 |

| JT9D-20 | 49,400 lbf (219.74 kN) | 8,450 lb (3,830 kg) | 128.2 in (3,260 mm) | 92.3 in (2,340 mm) | McDonnell Douglas DC-10/Boeing 747 |

| JT9D-7Q/7Q3 | 53,000 lbf (235.76 kN) | 9,295 lb (4,216 kg) | 132.1 in (3,360 mm) | 93.6 in (2,380 mm) | Boeing 747 |

| JT9D-59A/70A | 53,000 lbf (235.76 kN) | 9,155 lb (4,153 kg) | 132.2 in (3,360 mm) | 93.6 in (2,380 mm) | McDonnell Douglas DC-10/Boeing 747/Airbus A300 |

| JT9D-7R4D/D1 | 48,000 lbf (213.51 kN) | 8,905 lb (4,039 kg) | 132.7 in (3,370 mm) | 93.4 in (2,370 mm) | Boeing 767/Airbus A310 |

| JT9D-7R4G2 | 54,750 lbf (243.54 kN) | 8,935 lb (4,053 kg) | 132.7 in (3,370 mm) | 93.4 in (2,370 mm) | Boeing 747 |

| JT9D-7R4H1 | 56,000 lbf (249.10 kN) | 8,885 lb (4,030 kg) | 132.7 in (3,370 mm) | 93.4 in (2,370 mm) | Airbus A300 |

See also

Related development

Comparable engines

Related lists

References

Notes

- ↑ Gunston 1989, p.126.

- ↑ Aero Engines 1968, Flight International, 4 January 1968.

- ↑ "JT9D ENGINE". Retrieved 5 January 2014.

- ↑ "Thrust Data for Performance Calculations" (pdf). Figure D9. Retrieved 5 January 2014.

Bibliography

- Gunston, Bill. World Encyclopedia of Aero Engines. Cambridge, England. Patrick Stephens Limited, 1989. ISBN 1-85260-163-9

External links

| Wikimedia Commons has media related to Pratt & Whitney JT9D. |