Occupational exposure banding

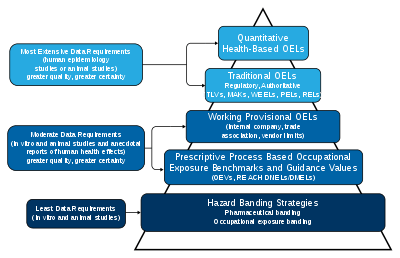

Occupational exposure banding, also known as hazard banding, is a process intended to quickly and accurately assign chemicals into specific categories (bands), each corresponding to a range of exposure concentrations designed to protect worker health. These bands are assigned based on a chemical’s toxicological potency and the adverse health effects associated with exposure to the chemical.[1] The output of this process is an occupational exposure band (OEB). Occupational exposure banding has been used by the pharmaceutical sector and by some major chemical companies over the past several decades to establish exposure control limits or ranges for new or existing chemicals that do not have formal OELs.[2] Furthermore, occupational exposure banding has become an important component of the Hierarchy of Occupational Exposure Limits (OELs).[3][4]

The U.S. National Institute for Occupational Safety and Health (NIOSH) has proposed a process that could be used to apply occupational exposure banding to a broader spectrum of occupational settings. The proposed NIOSH occupational exposure banding process utilizes available, but often limited, toxicological data to determine a potential range of chemical exposure levels that can be used as targets for exposure controls to reduce risk among workers.[5] An OEB is not meant to replace an OEL, rather it serves as a starting point to inform risk management decisions.[6]

Purpose

Occupational Exposure Limits (OELs) play a critical role in protecting workers from exposure to dangerous concentrations of hazardous material.[7] In the absence of an OEL, determining the controls needed to protect workers from chemical exposures can be challenging.[3] According to the U.S. Environmental Protection Agency, the Toxic Substances Control Act Chemical Substance Inventory currently contains over 85,000 chemicals that are commercially available, but a quantitative health-based OEL has been developed for only about 1,000 of these chemicals.[8] Furthermore, the rate at which new chemicals are being introduced into commerce significantly outpaces OEL development, creating a need for guidance on thousands of chemicals that lack reliable exposure limits.[5][9][10]

The NIOSH occupational exposure banding process is being created to provide a reliable approximation of a safe exposure level for potentially hazardous and unregulated chemicals in the workplace.[5] Occupational exposure banding uses limited chemical toxicity data to group chemicals into one of five bands. These bands, called occupational exposure bands (OEBs), define the range of exposures expected to protect worker health. Furthermore, going through the occupational exposure banding process may identify potential health effects and target organs, identify health risks that should be included in health communications, inform decisions regarding control interventions, inform medical surveillance decisions, and provide critical information on chemical potency quickly. One major benefit of the proposed occupational exposure banding process is that the requirements for time and data to categorize a chemical into an OEB are less than those required to develop an OEL.[1]

Assignment process

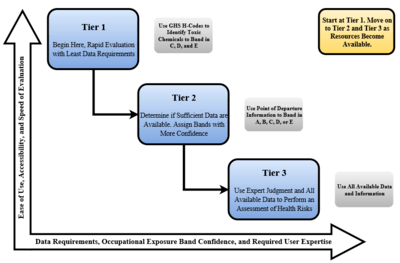

The proposed NIOSH occupational exposure banding process utilizes a three-tiered approach.[1] Each tier of the process has different requirements for data sufficiency, which allows stakeholders to use the occupational exposure banding process in many different situations. Selection of the most appropriate tier for a specific banding situation depends on the quantity and quality of the available data and the training and expertise of the user. Tier 1 produces a qualitative occupational exposure band (OEB) assignment based on Globally Harmonized System of Classification and Labeling of Chemicals (GHS); it involves assigning the OEB based on criteria aligned with specific GHS hazard codes and categories. Tier 2 produces a semi-quantitative OEB assignment based on secondary sources; it involves assigning the OEB on the basis of key findings from prescribed literature sources, including use of data from specific types of studies. Tier 3 relies on expert judgement to produce a band based on primary and secondary data that is available to the user.[5]

The process places chemicals into one of five bands, designated A through E. Each band is associated with a specific range of exposure concentrations. Band E represents the lowest range of exposure concentrations, while Band A represents the highest range. Assignment of a chemical to a band is based on both the potency of the chemical and the severity of the health effect. Band A and band B include chemicals with reversible health effects or produce adverse effects at only high concentration levels. Band C, band D, or band E include chemicals with serious or irreversible effects and those that cause problems at low concentration ranges.[1] The draft resulting airborne concentration target ranges are:[6]

| Occupational Exposure Band | A | B | C | D | E |

|---|---|---|---|---|---|

| Airborne Target Range for Particulate Concentration (mg/m3) | >10 mg/m3 | >1 to 10 mg/m3 | >0.1 to 1 mg/m3 | >0.01 to 0.1 mg/m3 | ≤0.01 mg/m3 |

| Airborne Target Range for Gas or Vapor Concentration (ppm) | >100 ppm | >10 to 100 ppm | >1 to 10 ppm | >0.1 to 1 ppm | ≤0.1 ppm |

Limitations

Although occupational exposure banding holds a great deal of promise for the occupational hygiene profession, there are potential limitations that should be considered. As with any analysis, the outcome of the NIOSH occupational exposure banding process – the OEB – is dependent upon the quantity and the quality of data used and the expertise of the individual using the process.[5] In order to maximize data quality, NIOSH has compiled a list of NIOSH-recommended sources which can provide data that can be used for banding.[11] Furthermore, for some chemicals the amount of quality data may not be sufficient to derive an OEB. It is important to note that the lack of data does not indicate that the chemical is safe. Other risk management strategies, such as control banding, can then be applied.[12]

Control banding versus exposure banding

The proposed NIOSH occupational exposure banding process guides a user through the evaluation and selection of critical health hazard information to select an OEB from among five categories of severity. For OEBs, the process uses only hazard-based data (e.g., studies on human health effects or toxicology studies) to identify an overall level of hazard potential and associated airborne concentration range for chemicals with similar hazard profiles. While the output of this process can be used by informed occupational safety and health professionals to make risk management and exposure control decisions, the process does not supply such recommendations directly.[13]

In contrast, control banding is a strategy that groups workplace risks into control categories or bands based on combinations of both hazard and exposure information.[10][14][15] Control banding combines hazard banding with exposure risk management and exposure management to directly link hazard to specific control measures.[15][16][17][18]

References

- 1 2 3 4 "The NIOSH Decision Logic for OEBs". The Synergist. American Industrial Hygiene Association. March 2016. Archived from the original on 2017-04-19. Retrieved 2017-04-10.

- ↑ Naumann, Bruce D.; Sargent, Edward V.; Starkman, Barry S.; Fraser, William J.; Becker, Gail T.; Kirk, G. David (1996-01-01). "Performance-Based Exposure Control Limits for Pharmaceutical Active Ingredients". American Industrial Hygiene Association Journal. 57 (1): 33–42. doi:10.1080/15428119691015197. ISSN 0002-8894. PMID 8588551.

- 1 2 "The Hierarchy of OELs: A New Organizing Principal for Occupational Risk Assessment" (PDF). The Synergist. American Industrial Hygiene Association. March 2014. Archived (PDF) from the original on 2017-04-19. Retrieved 2017-04-10.

- ↑ Deveau, M.; Chen, C-P; Johanson, G.; Krewski, D.; Maier, A.; Niven, K. J.; Ripple, S.; Schulte, P. A.; Silk, J. (2015-11-25). "The Global Landscape of Occupational Exposure Limits—Implementation of Harmonization Principles to Guide Limit Selection". Journal of Occupational and Environmental Hygiene. 12 (sup1): S127–S144. doi:10.1080/15459624.2015.1060327. ISSN 1545-9624. PMC 4654639. PMID 26099071.

- 1 2 3 4 5 "The Banding Marches On" (PDF). The Synergist. American Industrial Hygiene Association. May 2014. Archived (PDF) from the original on 2017-04-20. Retrieved 2017-04-10.

- 1 2 "NIOSH Docket: The Occupational Exposure Banding Process: Guidance for the Evaluation of Chemical Hazards". U.S. National Institute for Occupational Safety and Health. March 2017. Archived from the original on 2017-05-09. Retrieved 2017-04-24.

- ↑ Schulte, P. A.; Murashov, V.; Zumwalde, R.; Kuempel, E. D.; Geraci, C. L. (2010-08-01). "Occupational exposure limits for nanomaterials: state of the art". Journal of Nanoparticle Research. 12 (6): 1971–1987. doi:10.1007/s11051-010-0008-1. ISSN 1388-0764.

- ↑ "TSCA Chemical Substance Inventory". U.S. Environmental Protection Agency. Archived from the original on 2017-04-13. Retrieved 2017-04-10.

- ↑ "Request for Information on Updating OSHA's Chemical Permissible Exposure Limits". U.S. Occupational Safety and Health Administration. Archived from the original on 2017-04-19. Retrieved 2017-04-10.

- 1 2 Zalk, David M.; Nelson, Deborah Imel (2008-04-09). "History and Evolution of Control Banding: A Review". Journal of Occupational and Environmental Hygiene. 5 (5): 330–346. doi:10.1080/15459620801997916. ISSN 1545-9624. PMID 18350442.

- ↑ "Occupational Exposure Banding Resources". U.S. National Institute for Occupational Safety and Health. 2017-03-15. Archived from the original on 2017-04-21. Retrieved 2017-04-20.

- ↑ "Approach to Occupational Exposure Banding". U.S. National Institute for Occupational Safety and Health. 2017-03-15. Retrieved 2017-04-20.

- ↑ "Occupational Exposure Banding". U.S. National Institute for Occupational Safety and Health. Archived from the original on 2017-04-19. Retrieved 2017-04-18.

- ↑ Zalk, David M.; Kamerzell, Ryan; Paik, Samuel; Kapp, Jennifer; Harrington, Diana; Swuste, Paul (2010-01-01). "Risk Level Based Management System: A Control Banding Model for Occupational Health and Safety Risk Management in a Highly Regulated Environment". Industrial Health. 48 (1): 18–28. doi:10.2486/indhealth.48.18. Archived from the original on 2017-04-19.

- 1 2 Guidance for Conducting Control Banding Analyses. America Industrial Hygiene Association. 2007-01-01. ISBN 9781931504812.

- ↑ "Control of substances hazardous to health (Sixth edition)". UK Health and Safety Executive. 2013. ISBN 9780717665822. Archived from the original on 2017-01-13. Retrieved 2017-04-18.

- ↑ "Qualitative Risk Characterization and Management of Occupational Hazards: Control Banding (CB)". U.S. National Institute for Occupational Safety and Health. August 2009. Archived from the original on 2017-04-19. Retrieved 2017-04-18.

- ↑ "Control Banding". U.S. National Institute for Occupational Safety and Health. Archived from the original on 2017-04-19. Retrieved 2017-04-18.

External links

- The NIOSH Occupational Exposure Banding Process: Guidance for the Evaluation of Chemical Hazards Current Intelligence Bulletin

- The NIOSH Occupational Exposure Banding Topic Page

- The NIOSH Occupational Exposure Banding e-Tool

- Occupational Exposure Banding – A Conversation with Lauralynn Taylor McKernan, ScD CIH

- The NIOSH Control Banding Topic Page