Matrix (printing)

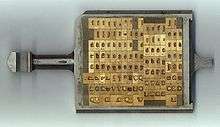

In the manufacture of metal type used in letterpress printing, a matrix, from the Latin meaning womb or a female breeding animal, is the mould used to cast a letter, known as a sort.[4] Matrices for printing types were made of copper.[5]

However, in printmaking the matrix is whatever is used, with ink, to hold the image that makes up the print, whether a plate in etching and engraving or a woodblock in woodcut.

Description

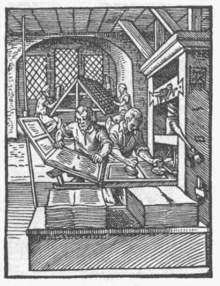

In letterpress or "cold metal" typesetting, used from the beginning of printing to the late nineteenth century, the matrix of one letter is inserted into the bottom of a hand mould, the mould is locked and molten type metal is poured into a straight-sided vertical cavity above the matrix. When the metal has cooled and solidified the mould is unlocked and the newly cast metal sort is removed. The matrix can then be reused to produce more copies of the sort.[6] The sorts could then be cleaned up and sent to the printer. Matrices could be used for many castings of type.

In the hot metal typesetting systems of the later years of metal type printing, from the late nineteenth century onwards, new type is cast for each job under the control of a keyboard. The matrix or mats for a complete font are loaded into a matrix-case and inserted into a casting machine, which casts the required sorts for a page composition automatically, often from a paper reel.

The standard method to make a matrix was to drive a steel punch in the shape of the type to be made into soft copper.[9] The matrix would then be cleaned up and cut down to the width of the letter to be cast.

From the nineteenth century additional technologies arrived to make matrices. The first was electrotyping from the 1840s, which forms a copper matrix around a pattern letter by electrodeposition of copper.[lower-alpha 1] The advantage of electrotyping was that the pattern letter did not have to be out of hard steel, so it could be cut in soft type metal much faster than a punch could, and this allowed an explosion in the number of display typefaces available.[11] It also allowed printers to form matrices for types for which they did not have matrices, or duplicate matrices when they had no punches, and accordingly was less honourably used to pirate typefaces from other foundries.[11] The matrices formed were sometimes fragile and the technology was most commonly used for larger and more esoteric display typefaces.[11] An additional technology from the 1880s was the direct engraving of punches (or, especially for larger fonts, matrices) using a pantograph cutting machine, controlled by replicating hand movements at a smaller size. This allowed rapid production of punches for issuing the same design in many sizes.

Large typefaces were never very easily produced by punching since it was hard to drive large punches evenly. Early alternative methods used included printing from wood types, direct manufacture of a matrix, 'dabbing', where wood-blocks were punched into metal softened by heating, or carefully casting type or matrices in moulds made of softer materials than copper such as sand, clay, plaster, papier mâché or punched lead.[12][13][14][15] One solution to the problem in the early nineteenth century was William Caslon IV's riveted "Sanspareil" matrices formed by cut-out from layered sheets. The problem was ultimately solved in the mid-nineteenth century by new technologies, electrotyping and pantograph engraving, the latter both for wood type and then for matrices.

See also

References

- ↑ "Jannon". French Ministry of Culture.

- ↑ "Monotype Garamond". Fonts.com. Monotype. Retrieved 4 July 2015.

- ↑ "Garamond". Microsoft. Retrieved 4 July 2015.

- ↑ Man, John The Gutenberg Revolution:The story of a genius that changed the world © 2002 Headline Book Publishing, a division of Hodder Headline, London. ISBN 0-7472-4504-5. A detailed examination of Gutenberg's life and invention interwoven with the underlying social and religious upheaval of Medieval Europe on the eve of the Renaissance.

- ↑ Theodore Low De Vinne (1899). The Practice of Typography: A Treatise on the Processes of Type-making, the Point System, the Names, Sizes, Styles, and Prices of Plain Printing Types. Century Company. pp. 9–36.

- ↑ Meggs, Philip B. A History of Graphic Design. John Wiley & Sons, Inc. 1998. (pp 58–69) ISBN 0-471-29198-6

- ↑ "Monotype matrices and moulds in the making" (PDF). Monotype Recorder. 40 (3). 1956.

- ↑ Morison, Stanley. "Printing the Times". Eye. Retrieved 28 July 2015.

- ↑ Tracy, Walter. Letters of Credit. pp. 32–40.

- ↑ Howes, Justin (2000). "Caslon's punches and matrices". Matrix. 20: 1–7.

- 1 2 3 MacMillan, David. "Patrix Cutting and Matrix Electroforming: A Survey of the Data". Circuitous Root. Retrieved 6 October 2017.

- ↑ Mosley, James. "c: a mystery resolved?". Type Foundry (blog). Retrieved 5 October 2017.

- ↑ Mosley, James. "Big brass matrices again: the Enschedé 'Chalcographia' type". Type Foundry (blog). Retrieved 5 October 2017.

- ↑ Mosley, James. "Dabbing, abklatschen, clichage..." Type Foundry (blog). Retrieved 5 October 2017.

- ↑ "Ornamented types: a prospectus" (PDF). imimprimit. Archived from the original (PDF) on 22 December 2015. Retrieved 12 December 2015.

- ↑ One problem with electrotyping is that the newly formed letter is slightly smaller than the original letter - a shrinkage of about 0.0038%. While not a great problem for a single electrotyping, the effect could multiply in letters repeatedly copied. According to Justin Howes, sometimes type to be electrotyped was squashed slightly in a press or filed down to compensate before it was duplicated.[10]