Joule heating

Joule heating, also known as Ohmic heating and resistive heating, is the process by which the passage of an electric current through a conductor produces heat.

Joule's first law, also known as the Joule–Lenz law,[1] states that the power of heating generated by an electrical conductor is proportional to the product of its resistance and the square of the current:

Joule heating affects the whole electric conductor, unlike the Peltier effect which transfers heat from one electrical junction to another.

History

James Prescott Joule first published in December 1840, an abstract in the Proceedings of the Royal Society, suggesting that heat could be generated by an electrical current. Joule immersed a length of wire in a fixed mass of water and measured the temperature rise due to a known current flowing through the wire for a 30 minute period. By varying the current and the length of the wire he deduced that the heat produced was proportional to the square of the current multiplied by the electrical resistance of the immersed wire.[2]

In 1841 and 1842, subsequent experiments showed that the amount of heat generated was proportional to the chemical energy used in the voltaic pile that generated the current. This led Joule to reject the caloric theory (at that time the dominant theory) in favor of the mechanical theory of heat (according to which heat is another form of energy).[2]

Resistive heating was independently studied by Heinrich Lenz in 1842.[1]

The SI unit of energy was subsequently named the joule and given the symbol J. The commonly known unit of power, the watt, is equivalent to one joule per second.

Microscopic description

Joule heating is caused by interactions between charge carriers (usually electrons) and the body of the conductor (usually atomic ions).

A voltage difference between two points of a conductor creates an electric field that accelerates charge carriers in the direction of the electric field, giving them kinetic energy. When the charged particles collide with ions in the conductor, the particles are scattered; their direction of motion becomes random rather than aligned with the electric field, which constitutes thermal motion. Thus, energy from the electrical field is converted into thermal energy.[3]

Power loss and noise

Joule heating is referred to as ohmic heating or resistive heating because of its relationship to Ohm's Law. It forms the basis for the large number of practical applications involving electric heating. However, in applications where heating is an unwanted by-product of current use (e.g., load losses in electrical transformers) the diversion of energy is often referred to as resistive loss. The use of high voltages in electric power transmission systems is specifically designed to reduce such losses in cabling by operating with commensurately lower currents. The ring circuits, or ring mains, used in UK homes are another example, where power is delivered to outlets at lower currents, thus reducing Joule heating in the wires. Joule heating does not occur in superconducting materials, as these materials have zero electrical resistance in the superconducting state.

Resistors create electrical noise, called Johnson–Nyquist noise. There is an intimate relationship between Johnson–Nyquist noise and Joule heating, explained by the fluctuation-dissipation theorem.

Formulas

Direct current

The most general and fundamental formula for Joule heating is:

where

- P is the power (energy per unit time) converted from electrical energy to thermal energy,

- I is the current travelling through the resistor or other element,

- is the voltage drop across the element.

The explanation of this formula (P=VI) is:[4]

- (Energy dissipated per unit time) = (Energy dissipated per charge passing through resistor) × (Charge passing through resistor per unit time)

When Ohm's law is also applicable, the formula can be written in other equivalent forms:

where R is the resistance.

Alternating current

When current varies, as it does in AC circuits,

where t is time and P is the instantaneous power being converted from electrical energy to heat. Far more often, the average power is of more interest than the instantaneous power:

where "avg" denotes average (mean) over one or more cycles, and "rms" denotes root mean square.

These formulas are valid for an ideal resistor, with zero reactance. If the reactance is nonzero, the formulas are modified:

where is the phase difference between current and voltage, means real part, Z is the complex impedance, and Y* is the complex conjugate of the admittance (equal to 1/Z*).

For more details in the reactive case, see AC power∆0}

Differential form

In plasma physics, the Joule heating often needs to be calculated at a particular location in space. The differential form of the Joule heating equation gives the power per unit volume.

Here, is the current density, and is the electric field. For a neutral plasma not in magnetic field and with a conductivity , and therefore

where is the resistivity. This directly resembles the " " term of the macroscopic form.

High-voltage alternating current transmission of electricity

Overhead power lines transfer electrical energy from electricity producers to consumers. Those power lines have a nonzero resistance and therefore are subject to Joule heating, which causes transmission losses.

The split of power between transmission losses (Joule heating in transmission lines) and load (useful energy delivered to the consumer) can be approximated by a voltage divider. In order to minimize transmission losses, the resistance of the lines has to be as small as possible compared to the load (resistance of consumer appliances). Line resistance is minimized by the use of copper conductors, but the resistance and power supply specifications of consumer appliances are fixed.

Usually, a transformer is placed between the lines and consumption. When a high-voltage, low-intensity current in the primary circuit (before the transformer) is converted into a low-voltage, high-intensity current in the secondary circuit (after the transformer), the equivalent resistance of the secondary circuit becomes higher[5] and transmission losses are reduced in proportion.

During the War of Currents, AC installations could use transformers to reduce line losses by Joule heating, at the cost of higher voltage in the transmission lines, compared to DC installations.

Applications

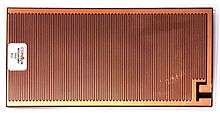

Joule-heating or resistive-heating is used in multiple devices and industrial process. The part which converts electricity into heat by Joule heating is called a heating element.

There are many practical uses of Joule heating:

- An incandescent light bulb glows when the filament is heated by Joule heating, due to thermal radiation (also called blackbody radiation).

- Electric fuses are used as a safety, breaking the circuit by melting if enough current flows to melt them.

- Electronic cigarettes vaporize propylene glycol and vegetable glycerine by Joule heating.

- Multiple heating devices use Joule heating, such as electric stoves, electric heaters, soldering irons, cartridge heaters.

- Some food processing equipment may make use of Joule heating: running current through food material (which behave as an electrical resistor) causes heat release inside the food.[6] The alternating electrical current coupled with the resistance of the food causes the generation of heat.[7] A higher resistance increases the heat generated. Ohmic heating allows for fast and uniform heating of food products, which keeps the high quality in foods. Products with particulates heat up faster in Ohmic heating (as compared to conventional heat processing) due to higher resistance.[8]

Food Processing

Joule heating (Ohmic Heating) is a flash pasteurization (also called "high-temperature short-time" (HTST)) aseptic process that runs an alternating current of 50–60 Hz through food.[9] Heat is generated through the electrical resistance of the food.[9] As the product heats up, electrical conductivity increases linearly.[7] A higher electrical current frequency is best as it reduces oxidation and metallic contamination.[9] This heating method is best for foods that contain particulates suspended in a weak salt containing medium due to their high resistance properties.[8] Ohmic heating allows for a maintained quality of foods due to the uniform heating that decreases deterioration and over-processing of food.[9]

Heating efficiency

As a heating technology, Joule heating has a coefficient of performance of 1.0, meaning that every joule of electrical energy supplied produces one joule of heat. In contrast, a heat pump can have a coefficient of more than 1.0 since it moves additional thermal energy from the environment to the heated item.

The definition of the efficiency of a heating process requires defining the boundaries of the system to be considered. When heating a building, the overall efficiency is different when considering heating effect per unit of electric energy delivered on the customer's side of the meter, compared to the overall efficiency when also considering the losses in the power plant and transmission of power.

Hydraulic equivalent

In the energy balance of groundwater flow a hydraulic equivalent of Joule's law is used:[10]

where:

- = loss of hydraulic energy ( ) due to friction of flow in -direction per unit of time (m/day) – comparable to

- = flow velocity in -direction (m/day) – comparable to

- = hydraulic conductivity of the soil (m/day) – the hydraulic conductivity is inversely proportional to the hydraulic resistance which compares to

See also

References

- 1 2 Джоуля — Ленца закон Archived 2014-12-30 at the Wayback Machine.. Большая советская энциклопедия, 3-е изд., гл. ред. А. М. Прохоров. Москва: Советская энциклопедия, 1972. Т. 8 (A. M. Prokhorov; et al., eds. (1972). "Joule–Lenz law". Great Soviet Encyclopedia (in Russian). 8. Moscow: Soviet Encyclopedia. )

- 1 2 "This Month Physics History: December 1840: Joule's abstract on converting mechanical power into heat". aps.org. American Physical society. Retrieved 16 September 2016.

- ↑ "Drift Velocity, Drift Current and Electron Mobility". Electrical4U. Retrieved 26 July 2017.

- ↑ Electric power systems: a conceptual introduction by Alexandra von Meier, p67, Google books link

- ↑ "Transformer circuits". Retrieved 26 July 2017.

- ↑ Ramaswamy, Raghupathy. "Ohmic Heating of Foods". Ohio State University. Archived from the original on 2013-04-08. Retrieved 2013-04-22.

- 1 2 Fellows, P.J (2009). Food Processing Technology. MA: Elsevier. pp. 813–844. ISBN 978-0-08-101907-8.

- 1 2 Varghese, K. Shiby; Pandey, M. C.; Radhakrishna, K.; Bawa, A. S. (October 2014). "Technology, applications and modelling of ohmic heating: a review". Journal of Food Science and Technology. 51 (10): 2304–2317. doi:10.1007/s13197-012-0710-3. ISSN 0022-1155. PMC 4190208. PMID 25328171.

- 1 2 3 4 1953-, Fellows, P. (Peter), (2017) [2016]. Food processing technology : principles and practice (4th ed.). Kent: Woodhead Publishing/Elsevier Science. ISBN 9780081019078. OCLC 960758611.

- ↑ R.J.Oosterbaan, J.Boonstra and K.V.G.K.Rao (1996). The energy balance of groundwater flow (PDF). In: V.P.Singh and B.Kumar (eds.), Subsurface-Water Hydrology, Vol.2 of the Proceedings of the International Conference on Hydrology and Water Resources, New Delhi, India. Kluwer Academic Publishers, Dordrecht, The Netherlands. pp. 153–160. ISBN 978-0-7923-3651-8.