Circlip

A circlip (a portmanteau of "circle" and "clip"), also known as a C-clip, Seeger ring, snap ring or Jesus clip,[1] is a type of fastener or retaining ring consisting of a semi-flexible metal ring with open ends which can be snapped into place, into a machined groove on a dowel pin or other part to permit rotation but to prevent lateral movement. There are two basic types: internal and external, referring to whether they are fitted into a bore or over a shaft. Circlips are often used to secure pinned connections.

Details

When used to retain piston wrist pins or gudgeon pins, the clips are known as wrist pin clips, wrist pin retainers, or gudgeon pin clips . The most commonly used circlip for this application is a simple spring steel circlip, or plain wire ring.

Common examples include e-clips (e-ring) and the (both internal and external) snap ring or circlip. These general types of fasteners are sized to provide an interference fit onto (or into, in the case of an internal fastener) a groove or land when in use, such that they must be elastically deformed in order to install or remove them.

The term "Jesus clip" comes from the propensity of the clip's spring action to launch the clip at a high velocity when removing or installing, leading to remarks such as, "Oh Jesus, where did it go?"[2]

Installation and maintenance

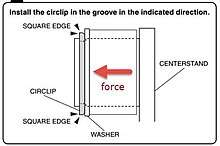

Because circlips are stamped out of sheet metal they have a smooth side and a rough side. The clip is installed with the smooth side facing the part and the rough side facing out, which prevents damage. Wet or dry lubrication is recommended to reduce friction against the circlip and maintain function.

Circlips are designed to be removed with special pliers that can be reassembled for internal or external clips. For expediency in the field, a pair of needle-nose pliers (for internal clips) or leverage with a flat-headed screwdriver (internal or external) is sometimes used.

Two holes in the ends of the circlip enable removal with specially shaped plier tips. Such clips are often referred to by their trade name: Tru-Arc clips or snap rings. They take both external and internal forms. Likewise Tru-Arc pliers exist in both compression (squeezing action) and expansion (spreading action) designs. Some Tru-Arc pliers are designed to be convertible between one type and another, with conversion achieved by moving the pliers' screw-in pivot.

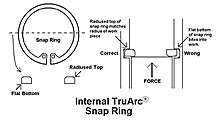

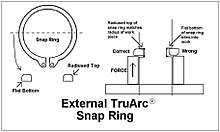

Since most Tru-Arc snap rings are stamped from sheet steel, they have a rounded side and a flat side. This is due to the stamping die behaving like a cookie cutter and causing a slight rounding of the upper edge of the cut clip. The Tru-Arc snap ring must always be installed with the rounded side of the ring facing the side of the retaining groove that holds the load or the force. This is because no machined groove can or should be machined with a square edge. Such an edge would constitute a stress riser, potentially causing the shaft or part to crack at the hat edge. The grooves into which snap rings are fitted are always machined with their edges (microscopically) rounded.

If a snap ring is positioned such that its flat side is pressed into the rounded edge of the groove then when load or force is applied, the flat edge of the snap ring will "bite" into the rounded edge of the retaining groove. The snap ring will distort and ride up the rounded edge, spreading an external snap ring and compressing an internal snap ring. This leaves the clip prone to being forced out of its groove and failure of retaining function. The accompanying images illustrate the correct orientation of the snap ring in its groove.

Installation Guidance from Honda Powersports

As discussed in the Honda Common Service Manual,[3] "Snap rings are always installed with the chamfered [rolled] edge facing away from the thrust of the mating part. This way, pressure against the snap ring presses against the areas in the snap ring groove with the most parallel contact area against one another. Installed incorrectly, pressure against the rolled or chamfered edge could compress the snap ring with the possibility of dislodging it."

The advice from Honda continues, "Never reuse snap rings since they are often used to control end play and become worn with normal use. Wear is especially critical on snap rings which retain spinning parts such as gears. After installing a snap ring, always rotate it in its groove to be sure it is fully seated."

References

- ↑ Zinn, Lennard (1998). Mountain Bike Performance Handbook. Osceola, Wisconsin: Velo Press, MBI Publishing Company. p. 157. ISBN 978-0-933201-95-8.

- ↑ Dalzell, Tom; Victor, Terry, eds. (November 27, 2014). The Concise New Partridge Dictionary of Slang and Unconventional English. Routledge. ISBN 9781317625117. Retrieved October 16, 2017 – via Google Books.

- ↑ "Honda Common Service Manual". Honda Powersports. 2013. Retrieved May 21, 2018.

External links

| Wikimedia Commons has media related to Circlips. |

| Wikimedia Commons has media related to Retaining ring pliers. |