Cyclohexanedimethanol

| Names | |

|---|---|

| IUPAC name

[4-(hydroxymethyl)cyclohexyl]methanol | |

| Other names

1,4–Cyclohexanedimethanol; CHDM; 1,4-Bis(hydroxymethyl)cyclohexane | |

| Identifiers | |

3D model (JSmol) |

|

| ChemSpider | |

| ECHA InfoCard | 100.002.972 |

PubChem CID |

|

| UNII | |

| |

| |

| Properties | |

| C8H16O2 | |

| Molar mass | 144.21 g/mol |

| Appearance | White waxy solid |

| Density | 1.02 g/ml |

| Melting point | 41 to 61 °C (106 to 142 °F; 314 to 334 K) |

| Boiling point | 284 to 288 °C (543 to 550 °F; 557 to 561 K) |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

Cyclohexanedimethanol (CHDM) is a mixture of isomeric organic compounds with formula C6H10(CH2OH)2. It is a colorless low-melting solid used in the production of polyester resins. Commercial samples consist of a mixture of cis and trans isomers. It is a di-substituted derivative of cyclohexane and is classified as a diol, meaning that it has two OH functional groups.

Production

CHDM is produced by catalytic hydrogenation of dimethyl terephthalate (DMT). The reaction conducted in two steps beginning with the conversion of DMT to the diester dimethyl 1,4-cyclohexanedicarboxylate (DMCD). In the second step DMCD is further hydrogenated to CHDM. The cis/trans ratio of CHDM is differ according to the catalyst, 80:20 for Cu4Ru12 catalyst, 65:35 in case of the RuPt catalyst, 88:12 for the Ru-Sn catalyst ,[1] 30:70 in case of the copper chromite catalyst usually used in industrial processing.[2]

- C6H4(CO2CH3)2 + 3 H2 → C6H10(CO2CH3)2

- C6H10(CO2CH3)2 + 4 H2 → C6H10(CH2OH)2 + 2 CH3OH

Byproduct of this process are 4-methylcyclohexanemethanol (CH3C6H10CH2OH) and the monoester methyl 4-methyl-4-cyclohexanecarboxylate (CH3C6H10CO2CH3, CAS registry number 51181-40-9).[3]

Most of the commercial CHDM has cis/trans ratio of 30:70. The leading producers in CHDM are Eastman Chemical in US and SK Chemicals in South Korea.

Applications

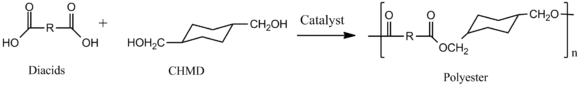

Via the process called polycondensation, CHDM is a precursor to polyesters. It is one of the most important co-monomers for production of polyethylene terephthalate (PET), or polyethylene terephthalic ester (PETE), from which plastic bottles are made.[4][5]

Thermoplastic polyesters containing CHDM exhibit enhanced strength, clarity, and solvent resistance. The exact properties of the polyesters vary from the high melting crystalline poly(1,4-cyclohexylenedimethylene terephthalate), PCT, to the non-crystalline copolyesters with the combination of ethylene glycol and CHDM in the backbone. The properties of these polyesters is also dependent on the cis/trans ratio of the CHDM monomer.[6] CHDM has low melting point and reduces the degree of crystallinity of PET homopolymer, improving its processability. With improved processability, the polymer tends to degrade less to acetaldehyde and other undesirable degradation products. The copolymer with PET is known as glycol-modified polyethylene terephthalate, PETG. PETG is used in many fields, including electronics, automobiles, barrier, and medicals etc.

References

- ↑ J. M. Thomas; R. Raja (2002). "The materials Chemistry of Inorganic Catalyst". Australian Journal of Chemistry. 54: 551–560. doi:10.1071/CH01150.

- ↑ S.R. Turner; Y. Li (2010). "Synthesis and Properties of Cyclic Diester Based Aliphatic Copolyesters". Journal of Polymer Science Part A: Polymer Chemistry. 48: 2162–2169. doi:10.1002/pola.23985.

- ↑ Peter Werle, Marcus Morawietz, Stefan Lundmark, Kent Sörensen, Esko Karvinen and Juha Lehtonen "Alcohols, Polyhydric" Ullmann's Encyclopedia of Industrial Chemistry, 2008, Wiley-VCH, Weinheim. doi:10.1002/14356007.a01_305.pub2

- ↑ S.R. Turner (2004). "Development of amorphous copolyesters based on 1,4- cyclohexane-dimethanol". Journal of Polymer Science Part A: Polymer Chemistry. 42: 5847–5852. doi:10.1002/pola.20460.

- ↑ S. Andjelic; D.D. Jamiolkowski; R. Bezwada (2007). "Mini-review The Polyoxaesters". Polymer International. 56: 1063–1077. doi:10.1002/pi.2257.

- ↑ S. R. Turner, R.W. Seymour; T.W. Smith (2001). "Cyclohexanedimethanol Polyesters". Encyclopedia of Polymer Science and Technology. doi:10.1002/0471440264.pst257.