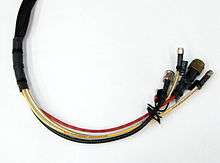

Cable harness

A cable harness, also known as a wire harness, cable assembly, wiring assembly or wiring loom, is an assembly of electrical cables or wires which transmit signals or electrical power. The cables are bound together by straps, cable ties, cable lacing, sleeves, electrical tape, conduit, a weave of extruded string, or a combination thereof.

Commonly used in automobiles, as well as construction machinery, cable harnesses provide several advantages over loose wires and cables. For example, many aircraft, automobiles and spacecraft contain many masses of wires which would stretch over several kilometres if fully extended. By binding the many wires and cables into a cable harness, the wires and cables can be better secured against the adverse effects of vibrations, abrasions, and moisture. By constricting the wires into a non-flexing bundle, usage of space is optimized, and the risk of a short is decreased. Since the installer has only one harness to install (as opposed to multiple wires), installation time is decreased and the process can be easily standardized. Binding the wires into a flame-retardant sleeve also lowers the risk of electrical fires.

Production

Cable harnesses are usually designed according to geometric and electrical requirements. A diagram is then provided (either on paper or on a monitor) for the assembly preparation and assembly.

The wires are first cut to the desired length, usually using a special wire-cutting machine. The wires may also be printed on by a special machine during the cutting process or on a separate machine. After this, the ends of the wires are stripped to expose the metal (or core) of the wires, which are fitted with any required terminals or connector housings. The cables are assembled and clamped together on a special workbench, or onto a pin board (assembly board), according to the design specification, to form the cable harness. After fitting any protective sleeves, conduit, or extruded yarn, the harness is either fitted directly in the vehicle or shipped.

In spite of increasing automation, hand manufacture continues to be the primary method of cable harness production in general, due to the many different processes involved, such as:

- routing wires through sleeves,

- taping with fabric tape, in particular on branch outs from wire strands,

- crimping terminals onto wires, particularly for so-called multiple crimps (more than one wire into one terminal),

- inserting one sleeve into another,

- fastening strands with tape, clamps or cable ties.

It is difficult to automate these processes, with major suppliers still using manual means of production, only automating portions of the process. Manual production remains more cost effective than automation, especially with small batch sizes.

Pre-production can be automated in part. This affects:

- Cutting individual wires (cutting machine),

- crimping terminals onto one or both sides of the wire,

- partial plugging of wires prefitted with terminals into connector housings (module),

- soldering of wire ends (solder machine)

- twisting wires.

A terminal in a wire harness is defined as device designed to terminate a conductor that is to be affixed to a post, stud, chassis, another conductor, etc., to establish an electrical connection. Some types of terminals include ring, tongue, spade, flag, hook, blade, quick-connect, offset and flagged. [1]

Testing the electrical functionality of a cable harness can be done with the aid of a test board. The circuit diagram data are pre-programmed into the test board, where harnesses can be tested individually or in multiple numbers.

In sound engineering

The cable harnesses used in sound engineering (stage and studio) for carrying audio signals are also called multicores.

Industry quality standard

Wiring harness quality standards are standardized by IPC's publication IPC/WHMA-A-620 for conforming and non-conforming requirements. Customer drawings, notes, or specifications take a higher priority to the IPC/WHMA-A-620 standard, but if no customer specifications are called for the default accept / reject is dictated by the 620 standard. IPC standards are reviewed every three years to ensure the requirements are up to date with technology, industry practices as well as other issues which may have transpired since the previous revision. The IPC/WHMA-A-620 standard covers issues such as electrostatic discharge protection), rework / repair, preparation of wire (stripping, strand damage, deformation, etc.), cleanliness, solder, crimping, pull-test requirements of crimps, hardware mounting, overmolding among other critical processing operations. All issues covered in the 620 standard are intended to provide the end user with a product which will fit their intended needs. There are three classes mentioned in the 620 standard:

- Class 1: general electronic products, that is, toys, non-critical items.

- Class 2: dedicated service electronic products, that is, uninterrupted service is desired but not critical

- Class 3: high performance / harsh environment electronic products, that is, must function when required, life-saving devices, military needs.