2-Methyltetrahydrofuran

| |

| Names | |

|---|---|

| Preferred IUPAC name

2-Methyloxolane | |

| Other names

2-Methyltetrahydrofuran, 2-Methyl-THF | |

| Identifiers | |

3D model (JSmol) |

|

| ChemSpider | |

| ECHA InfoCard | 100.002.281 |

| |

| |

| Properties | |

| C5H10O | |

| Molar mass | 86.13 g·mol−1 |

| Density | 0.854 g/mL |

| Melting point | −136 °C (−213 °F; 137 K)[1] |

| Boiling point | 80.2 °C (176.4 °F; 353.3 K)[1] |

| Hazards | |

| Safety data sheet | External MSDS |

Except where otherwise noted, data are given for materials in their standard state (at 25 °C [77 °F], 100 kPa). | |

| Infobox references | |

2-Methyltetrahydrofuran is an organic compound with the molecular formula CH3C4H7O. It is a highly flammable mobile liquid. It is mainly used as a replacement for THF in specialized applications for its better performance, such as to obtain higher reaction temperatures, or easier separations (as, unlike THF, it is not miscible with water). It is derived from sugars via furfural and is occasionally touted as a biofuel.

Structures and properties

2-Methyltetrahydrofuran is "inversely soluble" in water. That is, its solubility decreases with increasing temperature, which is a rare property.[2] 2-Methyltetrahydrofuran behaves like tetrahydrofuran as a Lewis base in organometallic reactions.[1]

Preparation

2-Methyltetrahydrofuran is usually synthesized by catalytic hydrogenation of furfural.

- OC4H3CHO + 4 H2 → OC4H7CH3 + H2O

Furfural is produced by the acid-catalyzed digestion of pentosan sugars, C5 polysaccharides, in biomass. Thus, the raw materials of 2-methyltetrahydrofuran are renewable biomass rich with cellulose, hemicelluloses, and lignin, such as corncobs or bagasse and other plant and agricultural waste.[3]

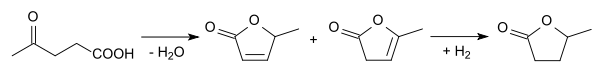

2-Methyltetrahydrofuran can also be produced starting from levulinic acid. Cyclization and reduction gives γ-valerolactone:

This lactone can be hydrogenated to 1,4-pentanediol, which can then be dehydrated to give 2-methyltetrahydrofuran:

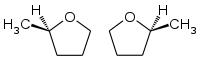

2-Methyltetrahydrofuran is chiral, so it exists in two enantiomeric forms. The commercial processes involving hydrogenation gives a racemic mixture. The asymmetric synthesis of (S)-(+)-2-methyltetrahydrofuran can achieved by using a wool–rhodium complex as a chiral catalyst for hydrogenation of methyl furan.[2]

Applications

2-Methyltetrahydrofuran is mainly used as a higher boiling substitute for tetrahydrofuran as a specialty solvent. It also is used in the electrolyte formulation for secondary lithium electrodes and as a component in alternative fuels. It is a valued solvent for low temperature reactions. 2-Methyltetrahydrofuran forms a glass, which does not crystallize, and is frequently used as a solvent for spectroscopic studies at −196 °C.[1]

Other common uses of 2-methyltetrahydrofuran is as a solvent for Grignard reagents used in organometallic and biphasic chemical processes, because of the oxygen atom's ability to coordinate to the magnesium ion component of the Grignard reagent, or to azeotropically dry products. The use of 2-methyltetrahydrofuran provides very clean organic-water phase separations. It is a popular, but costlier substitute for tetrahydrofuran.

2-Methyltetrahydrofuran is approved by the United States Department of Energy as an additive to gasoline. 2-Methyltetrahydrofuran Furfural and other partially hydrogenated/reduced furyl compounds between it and 2-methyltetrahydrofuran (furfuryl alcohol, methylfuran, tetrahydrofural alcohol) have a tendency to polymerize and are quite volatile. 2-Methyltetrahydrofuran itself, however, is more stable and less volatile, and thus is suitable for use as a motor fuel.

2-Methyltetrahydrofuran has been promoted as an ecologically-friendly alternative to THF.[4] Whereas 2-MeTHF is more expensive, it may provide for greater overall process economy. 2-MeTHF has solvating properties that are intermediate between diethyl ether and THF, has limited water miscibility, and forms an azeotrope with water on distillation. Its lower melting point makes it useful for lower temperature reactions, and its higher boiling point allows procedures under reflux at higher temperatures (relative to THF).

References

- 1 2 3 4 Aycock, David F. (2007). "Solvent Applications of 2-Methyltetrahydrofuran in Organometallic and Biphasic Reactions". Org. Proc. Res. Dev. 11: 156–159. doi:10.1021/op060155c.

- 1 2 He, Man; Zhou, Da-Qing; Ge, Hong-Li; Huang, Mei-Yu; Jiang, Ying-Yan (2003). "Catalytic Behavior of Wool-Rh Complex in Aymmetric Hydrogenation of 2-Methyl Furan". Polymer Advanced technology. 14: 273–277. doi:10.1002/pat.305.

- ↑ Hoydonckx, H. E.; Van Rhijn, W. M.; Van Rhijn, W.; De Vos, D. E.; Jacobs, P. A., "Furfural and Derivatives", Ullmann's Encyclopedia of Industrial Chemistry, Weinheim: Wiley-VCH, doi:10.1002/14356007.a12_119.pub2

- ↑ "Greener Solvent Alternatives – Brochure" (PDF). Sigmaaldrich.com. Retrieved 2010-02-15.

- Huber, George W.; Iborra, Sara; Corma, Avelino (2006). "Synthesis of Transportation Fuels from Biomass: Chemistry, Catalysts, and Engineering". Chemical Reviews. 106 (9): 4044–4098. doi:10.1021/cr068360d. PMID 16967928.

Further reading

- Zheng, Hong-Yan; Zhu, Yu-Lei; Teng, Bo-Tao; Bai, Zong-Qing; Zhang, Cheng-Hua; Xiang, Hong-Wei; Li, Yong-Wang (2006). "Towards understanding the reaction pathway in vapor phasehydrogenation of furfural to 2-methylfuran". Journal of Molecular Catalysis A, Chemical. 246: 18. doi:10.1016/j.molcata.2005.10.003.