< Biomedical Engineering Theory And Practice

Classes of Biomaterials

Metals and alloys as biomaterials

Table 6. Mechanical properties of biomaterials

| Material | Tensile strength (MPa) | Compressive strength (MPa) | Elastic modulus (GPa) | Fracture toughness (MPa. m-1/2) |

|---|---|---|---|---|

| Cortical Bone | 50-151[1] | 100-230[2] | 7-30[3] | 2-12[3] |

| Titanium | 345[4] | 250-600[5] | 102.7[4] | 58-66[4] |

| Stainless steel | 465-950[6] | 1000[5] | 200[1] | 55-95[5] |

| Ti-Alloys | 596-1100[4] | 450-1850[5] | 55-114[4] | 40-92[4] |

| Alumina | 270-500[5] | 3000-5000[5] | 380-410[3] | 5-6[3] |

Ceramics as biomaterials

Table 7: Bioceramics Applications [7]

| Devices | Function | Biomaterial |

|---|---|---|

| Artificial total hip, knee, shoulder, elbow, wrist | Reconstruct arthritic or fractured joints | High-density alumina, metal bioglass coatings |

| Bone plates, screws, wires | Repair fractures | Bioglass-metal fiber composite, Polysulfone-carbon fiber composite |

| Intramedullary nails | Align fractures | Bioglass-metal fiber composite, Polysulfone-carbon fiber composite |

| Harrington rods | Correct chronic spinal curvature | Bioglass-metal fiber composite, Polysulfone-carbon fiber composite |

| Permanently implanted artificial limbs | Replace missing extremities | Bioglass-metal fiber composite, Polysulfone-carbon fiber composite |

| Vertebrae Spacers and extensors | Correct congenital deformity | Al2O3 |

| Spinal fusion | Immobilize vertebrae to protect spinal cord | Bioglass |

| Alveolar bone replacements, mandibular reconstruction | Restore the alveolar ridge to improve denture fit | Polytetra fluro ethylene (PTFE) - carbon composite, Porous Al2O3, Bioglass, dense-apatite |

| End osseous tooth replacement implants | Replace diseased, damaged or loosened teeth | Al2O3, Bioglass, dense hydroxyapatite, vitreous carbon |

| Orthodontic anchors | Provide posts for stress application required to change deformities | Bioglass-coated Al2O3, Bioglass coated vitallium |

Table 2: Mechanical Properties of Ceramic Biomaterials [7]

| Material | Young’s Modulus (GPa) | CompressiveStrength (MPa) | Bond strength (GPa) | Hardness | Density (g/cm3) |

|---|---|---|---|---|---|

| Inert Al2O3 | 380 | 4000 | 300-400 | 2000-3000(HV) | >3.9 |

| ZrO2 (PS) | 150-200 | 2000 | 200-500 | 1000-3000(HV) | ≈6.0 |

| Graphite | 20-25 | 138 | NA | NA | 1.5-1.9 |

| (LTI)Pyrolitic Carbon | 17-28 | 900 | 270-500 | NA | 1.7-2.2 |

| Vitreous Carbon | 24-31 | 172 | 70-207 | 150-200(DPH) | 1.4-1.6 |

| Bioactive HAP | 73-117 | 600 | 120 | 350 | 3.1 |

| Bioglass | ≈75 | 1000 | 50 | NA | 2.5 |

| AW Glass Ceramic | 118 | 1080 | 215 | 680 | 2.8 |

| Bone | 3-30 | 130-180 | 60-160 | NA | NA |

Polymers as biomaterials

Composite as biomaterials

Biodegradable Polymers as Biomaterials

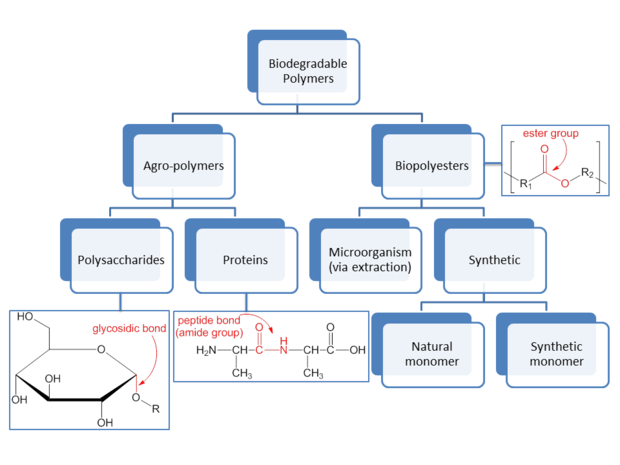

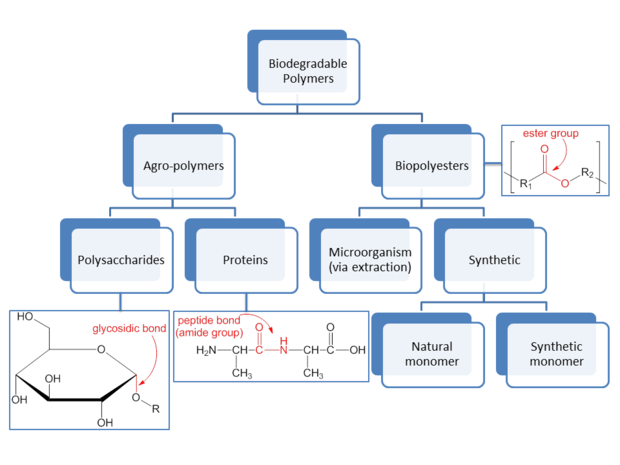

Generally, biodegradable polymers is composed of ester, amide, or ether bonds. These biodegradable polymers can be categorized into two groups based on their structure and synthesis. One of these groups is agro-polymers, or those derived from biomass[8]. The other consists of biopolyesters, derived from microorganisms or synthetically made from either naturally or synthetic monomers.

Biodegradable polymers organization based on structure and occurrence [8]

Biopolyesters as Biomaterials

Agro-polymers as Biomaterials

- 1 2 Chen, Q., Zhu, C., & Thouas, G. A. (2012). Progress and challenges in biomaterials used for bone tissue engineering: bioactive glasses and elastomeric composites. Progress in Biomaterials, 1(1), 1-22

- ↑ Kokubo, T., Kim, H. M., & Kawashita, M. (2003). Novel bioactive materials with different mechanical properties. Biomaterials, 24(13), 2161-2175.

- 1 2 3 4 Amaral, M., Lopes, M. A., Silva, R. F., & Santos, J. D. (2002). Densification route and mechanical properties of Si 3 N 4–bioglass biocomposites. Biomaterials, 23(3), 857-862

- 1 2 3 4 5 6 Niinomi, M. (1998). Mechanical properties of biomedical titanium alloys.Materials Science and Engineering: A, 243(1), 231-236.

- 1 2 3 4 5 6 NPTEL >> Metallurgy and Material Science >> Introduction to Biomaterials (Video) >> Lecture-01-Introduction to basic concepts of Biomaterials Science;

- ↑ Katti, K. S. (2004). Biomaterials in total joint replacement. Colloids and Surfaces B: Biointerfaces, 39(3), 133-142.

- 1 2 Thamaraiselvi, T. V., and S. Rajeswari. “Biological evaluation of bioceramic materials-a review.” Carbon 24.31 (2004): 172.

- 1 2 editors, Luc Avérous, Eric Pollet, (2012). Environmental silicate nano-biocomposites. London: Springer. ISBN 978-1-4471-4108-2.

This article is issued from

Wikibooks.

The text is licensed under Creative

Commons - Attribution - Sharealike.

Additional terms may apply for the media files.