Tungsten

Tungsten, or wolfram,[7][8] is a chemical element with the symbol W and atomic number 74. The name tungsten comes from the former Swedish name for the tungstate mineral scheelite, tungsten which means "heavy stone".[9] Tungsten is a rare metal found naturally on Earth almost exclusively combined with other elements in chemical compounds rather than alone. It was identified as a new element in 1781 and first isolated as a metal in 1783. Its important ores include wolframite and scheelite.

| |||||||||||||||||||||||||||||||||||||||||

| Tungsten | |||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pronunciation | /ˈtʌŋstən/ | ||||||||||||||||||||||||||||||||||||||||

| Alternative name | wolfram, pronounced: /ˈwʊlfrəm/ (WUUL-frəm) | ||||||||||||||||||||||||||||||||||||||||

| Appearance | grayish white, lustrous | ||||||||||||||||||||||||||||||||||||||||

| Standard atomic weight Ar, std(W) | 183.84(1)[1] | ||||||||||||||||||||||||||||||||||||||||

| Tungsten in the periodic table | |||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||

| Atomic number (Z) | 74 | ||||||||||||||||||||||||||||||||||||||||

| Group | group 6 | ||||||||||||||||||||||||||||||||||||||||

| Period | period 6 | ||||||||||||||||||||||||||||||||||||||||

| Block | d-block | ||||||||||||||||||||||||||||||||||||||||

| Element category | Transition metal | ||||||||||||||||||||||||||||||||||||||||

| Electron configuration | [Xe] 4f14 5d4 6s2[2] | ||||||||||||||||||||||||||||||||||||||||

| Electrons per shell | 2, 8, 18, 32, 12, 2 | ||||||||||||||||||||||||||||||||||||||||

| Physical properties | |||||||||||||||||||||||||||||||||||||||||

| Phase at STP | solid | ||||||||||||||||||||||||||||||||||||||||

| Melting point | 3695 K (3422 °C, 6192 °F) | ||||||||||||||||||||||||||||||||||||||||

| Boiling point | 6203 K (5930 °C, 10706 °F) | ||||||||||||||||||||||||||||||||||||||||

| Density (near r.t.) | 19.3 g/cm3 | ||||||||||||||||||||||||||||||||||||||||

| when liquid (at m.p.) | 17.6 g/cm3 | ||||||||||||||||||||||||||||||||||||||||

| Heat of fusion | 52.31 kJ/mol[3][4] | ||||||||||||||||||||||||||||||||||||||||

| Heat of vaporization | 774 kJ/mol | ||||||||||||||||||||||||||||||||||||||||

| Molar heat capacity | 24.27 J/(mol·K) | ||||||||||||||||||||||||||||||||||||||||

Vapor pressure

| |||||||||||||||||||||||||||||||||||||||||

| Atomic properties | |||||||||||||||||||||||||||||||||||||||||

| Oxidation states | −4, −2, −1, 0, +1, +2, +3, +4, +5, +6 (a mildly acidic oxide) | ||||||||||||||||||||||||||||||||||||||||

| Electronegativity | Pauling scale: 2.36 | ||||||||||||||||||||||||||||||||||||||||

| Ionization energies |

| ||||||||||||||||||||||||||||||||||||||||

| Atomic radius | empirical: 139 pm | ||||||||||||||||||||||||||||||||||||||||

| Covalent radius | 162±7 pm | ||||||||||||||||||||||||||||||||||||||||

Color lines in a spectral range | |||||||||||||||||||||||||||||||||||||||||

| Other properties | |||||||||||||||||||||||||||||||||||||||||

| Natural occurrence | primordial | ||||||||||||||||||||||||||||||||||||||||

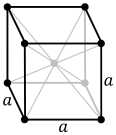

| Crystal structure | body-centered cubic (bcc) | ||||||||||||||||||||||||||||||||||||||||

| Speed of sound thin rod | 4620 m/s (at r.t.) (annealed) | ||||||||||||||||||||||||||||||||||||||||

| Thermal expansion | 4.5 µm/(m·K) (at 25 °C) | ||||||||||||||||||||||||||||||||||||||||

| Thermal conductivity | 173 W/(m·K) | ||||||||||||||||||||||||||||||||||||||||

| Electrical resistivity | 52.8 nΩ·m (at 20 °C) | ||||||||||||||||||||||||||||||||||||||||

| Magnetic ordering | paramagnetic[5] | ||||||||||||||||||||||||||||||||||||||||

| Magnetic susceptibility | +59.0·10−6 cm3/mol (298 K)[6] | ||||||||||||||||||||||||||||||||||||||||

| Young's modulus | 411 GPa | ||||||||||||||||||||||||||||||||||||||||

| Shear modulus | 161 GPa | ||||||||||||||||||||||||||||||||||||||||

| Bulk modulus | 310 GPa | ||||||||||||||||||||||||||||||||||||||||

| Poisson ratio | 0.28 | ||||||||||||||||||||||||||||||||||||||||

| Mohs hardness | 7.5 | ||||||||||||||||||||||||||||||||||||||||

| Vickers hardness | 3430–4600 MPa | ||||||||||||||||||||||||||||||||||||||||

| Brinell hardness | 2000–4000 MPa | ||||||||||||||||||||||||||||||||||||||||

| CAS Number | 7440-33-7 | ||||||||||||||||||||||||||||||||||||||||

| History | |||||||||||||||||||||||||||||||||||||||||

| Discovery | Carl Wilhelm Scheele (1781) | ||||||||||||||||||||||||||||||||||||||||

| First isolation | Juan José Elhuyar and Fausto Elhuyar (1783) | ||||||||||||||||||||||||||||||||||||||||

| Named by | Torbern Bergman (1781) | ||||||||||||||||||||||||||||||||||||||||

| Main isotopes of tungsten | |||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||

The free element is remarkable for its robustness, especially the fact that it has the highest melting point of all the elements discovered, melting at 3,422 °C (6,192 °F; 3,695 K). It also has the highest boiling point, at 5,930 °C (10,710 °F; 6,200 K).[10] Its density is 19.25 times that of water, comparable with that of uranium and gold, and much higher (about 1.7 times) than that of lead.[11] Polycrystalline tungsten is an intrinsically brittle[12][13] and hard material (under standard conditions, when uncombined), making it difficult to work. However, pure single-crystalline tungsten is more ductile and can be cut with a hard-steel hacksaw.[14]

Tungsten's many alloys have numerous applications, including incandescent light bulb filaments, X-ray tubes (as both the filament and target), electrodes in gas tungsten arc welding, superalloys, and radiation shielding. Tungsten's hardness and high density give it military applications in penetrating projectiles. Tungsten compounds are also often used as industrial catalysts.

Tungsten is the only metal from the third transition series that is known to occur in biomolecules that are found in a few species of bacteria and archaea. It is the heaviest element known to be essential to any living organism.[15] However, tungsten interferes with molybdenum and copper metabolism and is somewhat toxic to more familiar forms of animal life.[16][17]

Characteristics

Physical properties

In its raw form, tungsten is a hard steel-grey metal that is often brittle and hard to work. If made very pure, tungsten retains its hardness (which exceeds that of many steels), and becomes malleable enough that it can be worked easily.[14] It is worked by forging, drawing, or extruding but it is more commonly formed by sintering.

Of all metals in pure form, tungsten has the highest melting point (3,422 °C, 6,192 °F), lowest vapor pressure (at temperatures above 1,650 °C, 3,000 °F), and the highest tensile strength.[18] Although carbon remains solid at higher temperatures than tungsten, carbon sublimes at atmospheric pressure instead of melting, so it has no melting point. Tungsten has the lowest coefficient of thermal expansion of any pure metal. The low thermal expansion and high melting point and tensile strength of tungsten originate from strong covalent bonds formed between tungsten atoms by the 5d electrons.[19] Alloying small quantities of tungsten with steel greatly increases its toughness.[11]

Tungsten exists in two major crystalline forms: α and β. The former has a body-centered cubic structure and is the more stable form. The structure of the β phase is called A15 cubic; it is metastable, but can coexist with the α phase at ambient conditions owing to non-equilibrium synthesis or stabilization by impurities. Contrary to the α phase which crystallizes in isometric grains, the β form exhibits a columnar habit. The α phase has one third of the electrical resistivity[20] and a much lower superconducting transition temperature TC relative to the β phase: ca. 0.015 K vs. 1–4 K; mixing the two phases allows obtaining intermediate TC values.[21][22] The TC value can also be raised by alloying tungsten with another metal (e.g. 7.9 K for W-Tc).[23] Such tungsten alloys are sometimes used in low-temperature superconducting circuits.[24][25][26]

Isotopes

Naturally occurring tungsten consists of four stable isotopes (182W, 183W, 184W, and 186W) and one very long-lived radioisotope, 180W. Theoretically, all five can decay into isotopes of element 72 (hafnium) by alpha emission, but only 180W has been observed to do so, with a half-life of (1.8±0.2)×1018 years;[27][28] on average, this yields about two alpha decays of 180W per gram of natural tungsten per year.[29] The other naturally occurring isotopes have not been observed to decay, constraining their half-lives to be at least 4 × 1021 years.

Another 30 artificial radioisotopes of tungsten have been characterized, the most stable of which are 181W with a half-life of 121.2 days, 185W with a half-life of 75.1 days, 188W with a half-life of 69.4 days, 178W with a half-life of 21.6 days, and 187W with a half-life of 23.72 h.[29] All of the remaining radioactive isotopes have half-lives of less than 3 hours, and most of these have half-lives below 8 minutes.[29] Tungsten also has 11 meta states, with the most stable being 179mW (t1/2 6.4 minutes).

Chemical properties

Elemental tungsten resists attack by oxygen, acids, and alkalis.[30]

The most common formal oxidation state of tungsten is +6, but it exhibits all oxidation states from −2 to +6.[30][31] Tungsten typically combines with oxygen to form the yellow tungstic oxide, WO3, which dissolves in aqueous alkaline solutions to form tungstate ions, WO2−

4.

Tungsten carbides (W2C and WC) are produced by heating powdered tungsten with carbon. W2C is resistant to chemical attack, although it reacts strongly with chlorine to form tungsten hexachloride (WCl6).[11]

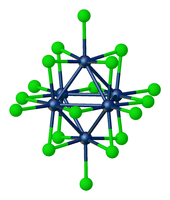

In aqueous solution, tungstate gives the heteropoly acids and polyoxometalate anions under neutral and acidic conditions. As tungstate is progressively treated with acid, it first yields the soluble, metastable "paratungstate A" anion, W

7O6–

24, which over time converts to the less soluble "paratungstate B" anion, H

2W

12O10–

42.[32] Further acidification produces the very soluble metatungstate anion, H

2W

12O6–

40, after which equilibrium is reached. The metatungstate ion exists as a symmetric cluster of twelve tungsten-oxygen octahedra known as the Keggin anion. Many other polyoxometalate anions exist as metastable species. The inclusion of a different atom such as phosphorus in place of the two central hydrogens in metatungstate produces a wide variety of heteropoly acids, such as phosphotungstic acid H3PW12O40.

Tungsten trioxide can form intercalation compounds with alkali metals. These are known as bronzes; an example is sodium tungsten bronze.

History

In 1781, Carl Wilhelm Scheele discovered that a new acid, tungstic acid, could be made from scheelite (at the time named tungsten).[33][34] Scheele and Torbern Bergman suggested that it might be possible to obtain a new metal by reducing this acid.[35] In 1783, José and Fausto Elhuyar found an acid made from wolframite that was identical to tungstic acid. Later that year, at the Royal Basque Society in the town of Bergara, Spain, the brothers succeeded in isolating tungsten by reduction of this acid with charcoal, and they are credited with the discovery of the element (they called it "wolfram" or "volfram").[36][37][38][39][40]

The strategic value of tungsten came to notice in the early 20th century. British authorities acted in 1912 to free the Carrock mine from the German owned Cumbrian Mining Company and, during World War I, restrict German access elsewhere.[41] In World War II, tungsten played a more significant role in background political dealings. Portugal, as the main European source of the element, was put under pressure from both sides, because of its deposits of wolframite ore at Panasqueira. Tungsten's desirable properties such as resistance to high temperatures, its hardness and density, and its strengthening of alloys made it an important raw material for the arms industry,[42][43] both as a constituent of weapons and equipment and employed in production itself, e.g., in tungsten carbide cutting tools for machining steel. Now tungsten is used in many more applications such as aircraft & motorsport ballast weights, darts, anti-vibration tooling, sporting equipment.

Etymology

The name "tungsten" (which means "heavy stone" in Swedish) is used in English, French, and many other languages as the name of the element, but not in the Nordic countries. "Tungsten" was the old Swedish name for the mineral scheelite. "Wolfram" (or "volfram") is used in most European (especially Germanic, Spanish and Slavic) languages and is derived from the mineral wolframite, which is the origin of the chemical symbol W.[14] The name "wolframite" is derived from German "wolf rahm" ("wolf soot" or "wolf cream"), the name given to tungsten by Johan Gottschalk Wallerius in 1747. This, in turn, derives from Latin "lupi spuma", the name Georg Agricola used for the element in 1546, which translates into English as "wolf's froth" and is a reference to the large amounts of tin consumed by the mineral during its extraction.[44]

Occurrence

Tungsten is found mainly in the minerals wolframite (iron–manganese tungstate (Fe,Mn)WO4, which is a solid solution of the two minerals ferberite FeWO4, and hübnerite MnWO4) and scheelite (calcium tungstate (CaWO4). Other tungsten minerals range in their level of abundance from moderate to very rare, and have almost no economical value.

Chemical compounds

Tungsten forms chemical compounds in oxidation states from -II to VI. Higher oxidation states, always as oxides, are relevant to its terrestrial occurrence and its biological roles, mid-level oxidation states are often associated with metal clusters, and very low oxidation states are typically associated with CO complexes. The chemistries of tungsten and molybdenum show strong similarities to each other, as well as contrasts with their lighter congener, chromium. The relative rarity of tungsten(III), for example, contrasts with the pervasiveness of the chromium(III) compounds. The highest oxidation state is seen in tungsten(VI) oxide (WO3).[45] Molybdenum trioxide, which is volatile at high temperatures, is the precursor to virtually all other Mo compounds as well as alloys. Tungsten(VI) oxide is soluble in aqueous base, forming tungstate (WO42−). This oxyanion condenses at lower pH values, forming polyoxotungstates.[46]

The broad range of oxidation states of tungsten is reflected in it various chlorides:[45]

- Tungsten(II) chloride, which exists as the hexamer W6Cl12

- Tungsten(III) chloride, which exists as the hexamer W6Cl18

- Tungsten(IV) chloride, WCl4, a black solid, which adopts a polymeric structure.

- Tungsten(V) chloride WCl5, a black solid which adopts a dimeric structure.

- Tungsten(VI) chloride WCl6, which contrasts with the instability of MoCl6.

Organotungsten compounds are numerous and also span a range of oxidation states. Notable examples include the trigonal prismatic W(CH3)6 and octahedral W(CO)6.

Production

.jpg)

The world's reserves of tungsten are 3,200,000 tonnes; they are mostly located in China (1,800,000 t), Canada (290,000 t),[47] Russia (160,000 t), Vietnam (95,000 t) and Bolivia. As of 2017, China, Vietnam and Russia are the leading suppliers with 79,000, 7,200 and 3,100 tonnes, respectively. Canada had ceased production in late 2015 due the closure of its sole tungsten mine. Meanwhile, Vietnam had significantly increased its output in the 2010s, owing to the major optimization of its domestic refining operations, and overtook Russia and Bolivia.[48]

China remains the world's leader not only in production, but also in export and consumption of tungsten products. The tungsten production gradually increases outside China because of the rising demand. Meanwhile, its supply by China is strictly regulated by the Chinese Government, which fights illegal mining and excessive pollution originating from mining and refining processes.[49]

Tungsten is considered to be a conflict mineral due to the unethical mining practices observed in the Democratic Republic of the Congo.[50][51]

There is a large deposit of tungsten ore on the edge of Dartmoor in the United Kingdom, which was exploited during World War I and World War II as the Hemerdon Mine. Following increases in tungsten prices, this mine was reactivated in 2014,[52] but ceased activities in 2018.[53]

Tungsten is extracted from its ores in several stages. The ore is eventually converted to tungsten(VI) oxide (WO3), which is heated with hydrogen or carbon to produce powdered tungsten.[35] Because of tungsten's high melting point, it is not commercially feasible to cast tungsten ingots. Instead, powdered tungsten is mixed with small amounts of powdered nickel or other metals, and sintered. During the sintering process, the nickel diffuses into the tungsten, producing an alloy.

Tungsten can also be extracted by hydrogen reduction of WF6:

- WF6 + 3 H2 → W + 6 HF

or pyrolytic decomposition:[54]

- WF6 → W + 3 F2 (ΔHr = +)

Tungsten is not traded as a futures contract and cannot be tracked on exchanges like the London Metal Exchange. The prices are usually quoted for tungsten concentrate or WO3.[48]

Applications

Approximately half of the tungsten is consumed for the production of hard materials – namely tungsten carbide – with the remaining major use being in alloys and steels. Less than 10% is used in other chemical compounds.[55] Because of the high ductile-brittle transition temperature of tungsten, its products are conventionally manufactured through powder metallurgy, spark plasma sintering, chemical vapor deposition, hot isostatic pressing, and thermoplastic routes. A more flexible manufacturing alternative is selective laser melting, which allows creating complex three-dimensional shapes.[56]

Hard materials

Tungsten is mainly used in the production of hard materials based on tungsten carbide, one of the hardest carbides, with a melting point of 2770 °C. WC is an efficient electrical conductor, but W2C is less so. WC is used to make wear-resistant abrasives, and "carbide" cutting tools such as knives, drills, circular saws, milling and turning tools used by the metalworking, woodworking, mining, petroleum and construction industries.[11] Carbide tooling is actually a ceramic/metal composite, where metallic cobalt acts as a binding (matrix) material to hold the WC particles in place. This type of industrial use accounts for about 60% of current tungsten consumption.[57]

The jewelry industry makes rings of sintered tungsten carbide, tungsten carbide/metal composites, and also metallic tungsten.[58] WC/metal composite rings use nickel as the metal matrix in place of cobalt because it takes a higher luster when polished. Sometimes manufacturers or retailers refer to tungsten carbide as a metal, but it is a ceramic.[59] Because of tungsten carbide's hardness, rings made of this material are extremely abrasion resistant, and will hold a burnished finish longer than rings made of metallic tungsten. Tungsten carbide rings are brittle, however, and may crack under a sharp blow.[60]

Alloys

The hardness and density of tungsten are applied in obtaining heavy metal alloys. A good example is high speed steel, which can contain as much as 18% tungsten.[61] Tungsten's high melting point makes tungsten a good material for applications like rocket nozzles, for example in the UGM-27 Polaris submarine-launched ballistic missile.[62] Tungsten alloys are used in a wide range of applications, including the aerospace and automotive industries and radiation shielding.[63] Superalloys containing tungsten, such as Hastelloy and Stellite, are used in turbine blades and wear-resistant parts and coatings.

Quenched (martensitic) tungsten steel (approx. 5.5% to 7.0% W with 0.5% to 0.7% C) was used for making hard permanent magnets, due to its high remanence and coercivity, as noted by John Hopkinson (1849–1898) as early as 1886. The magnetic properties of a metal or an alloy are very sensitive to microstructure. For example, while the element tungsten is not ferromagnetic (but iron is), when it is present in steel in these proportions, it stabilizes the martensite phase, which has greater ferromagnetism than the ferrite (iron) phase due to its greater resistance to magnetic domain wall motion.

Tungsten's heat resistance makes it useful in arc welding applications when combined with another highly-conductive metal such as silver or copper. The silver or copper provides the necessary conductivity and the tungsten allows the welding rod to withstand the high temperatures of the arc welding environment.

Armaments

Tungsten, usually alloyed with nickel and iron or cobalt to form heavy alloys, is used in kinetic energy penetrators as an alternative to depleted uranium, in applications where uranium's radioactivity is problematic even in depleted form, or where uranium's additional pyrophoric properties are not desired (for example, in ordinary small arms bullets designed to penetrate body armor). Similarly, tungsten alloys have also been used in cannon shells, grenades and missiles, to create supersonic shrapnel. Germany used tungsten during World War II to produce shells for anti-tank gun designs using the Gerlich squeeze bore principle to achieve very high muzzle velocity and enhanced armor penetration from comparatively small caliber and light weight field artillery. The weapons were highly effective but a shortage of tungsten used in the shell core limited that effectiveness.

Tungsten has also been used in Dense Inert Metal Explosives, which use it as dense powder to reduce collateral damage while increasing the lethality of explosives within a small radius.[64]

Chemical applications

Tungsten(IV) sulfide is a high temperature lubricant and is a component of catalysts for hydrodesulfurization.[65] MoS2 is more commonly used for such applications.[66]

Tungsten oxides are used in ceramic glazes and calcium/magnesium tungstates are used widely in fluorescent lighting. Crystal tungstates are used as scintillation detectors in nuclear physics and nuclear medicine. Other salts that contain tungsten are used in the chemical and tanning industries.[18] Tungsten oxide (WO3) is incorporated into selective catalytic reduction (SCR) catalysts found in coal-fired power plants. These catalysts convert nitrogen oxides (NOx) to nitrogen (N2) and water (H2O) using ammonia (NH3). The tungsten oxide helps with the physical strength of the catalyst and extends catalyst life.[67]

Niche uses

Applications requiring its high density include weights, counterweights, ballast keels for yachts, tail ballast for commercial aircraft, rotor weights for civil and military helicopters, and as ballast in race cars for NASCAR and Formula One.[68] Depleted uranium is also used for these purposes, due to similarly high density. Seventy-five-kg blocks of tungsten were used as "cruise balance mass devices" on the entry vehicle portion of the 2012 Mars Science Laboratory spacecraft. It is an ideal material to use as a dolly for riveting, where the mass necessary for good results can be achieved in a compact bar. High-density alloys of tungsten with nickel, copper or iron are used in high-quality darts[69] (to allow for a smaller diameter and thus tighter groupings) or for fishing lures (tungsten beads allow the fly to sink rapidly). Tungsten has seen use recently in nozzles for 3D printing; the high wear resistance and thermal conductivity of tungsten carbide improves the printing of abrasive filaments.[70] Some cello C strings are wound with tungsten. The extra density gives this string more projection and often cellists will buy just this string and use it with three strings from a different set.[71] Tungsten is used as an absorber on the electron telescope on the Cosmic Ray System of the two Voyager spacecraft.[72]

Gold substitution

Its density, similar to that of gold, allows tungsten to be used in jewelry as an alternative to gold or platinum.[14][73] Metallic tungsten is hypoallergenic, and is harder than gold alloys (though not as hard as tungsten carbide), making it useful for rings that will resist scratching, especially in designs with a brushed finish.

Because the density is so similar to that of gold (tungsten is only 0.36% less dense), and its price of the order of one-thousandth, tungsten can also be used in counterfeiting of gold bars, such as by plating a tungsten bar with gold,[74][75][76] which has been observed since the 1980s,[77] or taking an existing gold bar, drilling holes, and replacing the removed gold with tungsten rods.[78] The densities are not exactly the same, and other properties of gold and tungsten differ, but gold-plated tungsten will pass superficial tests.[74]

Gold-plated tungsten is available commercially from China (the main source of tungsten), both in jewelry and as bars.[79]

Electronics

Because it retains its strength at high temperatures and has a high melting point, elemental tungsten is used in many high-temperature applications,[80] such as Incandescent light bulb, cathode-ray tube, and vacuum tube filaments, heating elements, and rocket engine nozzles.[14] Its high melting point also makes tungsten suitable for aerospace and high-temperature uses such as electrical, heating, and welding applications, notably in the gas tungsten arc welding process (also called tungsten inert gas (TIG) welding).

Because of its conductive properties and relative chemical inertness, tungsten is also used in electrodes, and in the emitter tips in electron-beam instruments that use field emission guns, such as electron microscopes. In electronics, tungsten is used as an interconnect material in integrated circuits, between the silicon dioxide dielectric material and the transistors. It is used in metallic films, which replace the wiring used in conventional electronics with a coat of tungsten (or molybdenum) on silicon.[54]

The electronic structure of tungsten makes it one of the main sources for X-ray targets,[81][82] and also for shielding from high-energy radiations (such as in the radiopharmaceutical industry for shielding radioactive samples of FDG). It is also used in gamma imaging as a material from which coded apertures are made, due to its excellent shielding properties. Tungsten powder is used as a filler material in plastic composites, which are used as a nontoxic substitute for lead in bullets, shot, and radiation shields. Since this element's thermal expansion is similar to borosilicate glass, it is used for making glass-to-metal seals.[18] In addition to its high melting point, when tungsten is doped with potassium, it leads to an increased shape stability (compared with non-doped tungsten). This ensures that the filament does not sag, and no undesired changes occur.[83]

Nanowires

Through top-down nanofabrication processes, tungsten nanowires have been fabricated and studied since 2002.[84] Due to a particularly high surface to volume ratio, the formation of a surface oxide layer and the single crystal nature of such material, the mechanical properties differ fundamentally from those of bulk tungsten.[85] Such tungsten nanowires have potential applications in nanoelectronics and importantly as pH probes and gas sensors.[86] In similarity to silicon nanowires, tungsten nanowires are frequently produced from a bulk tungsten precursor followed by a thermal oxidation step to control morphology in terms of length and aspect ratio.[87] Using the Deal–Grove model it is possible to predict the oxidation kinetics of nanowires fabricated through such thermal oxidation processing.[88]

Fusion power

Due to its high melting point and good erosion resistance, tungsten is a lead candidate for the most exposed sections of the plasma-facing inner wall of nuclear fusion reactors. It will be used as the plasma-facing material of the divertor in the ITER reactor,[89] and is currently in use in the JET test reactor.

Biological role

Tungsten, at atomic number Z = 74, is the heaviest element known to be biologically functional. It is used by some bacteria and archaea,[90] but not in eukaryotes. For example, enzymes called oxidoreductases use tungsten similarly to molybdenum by using it in a tungsten-pterin complex with molybdopterin (molybdopterin, despite its name, does not contain molybdenum, but may complex with either molybdenum or tungsten in use by living organisms). Tungsten-using enzymes typically reduce carboxylic acids to aldehydes.[91] The tungsten oxidoreductases may also catalyse oxidations. The first tungsten-requiring enzyme to be discovered also requires selenium, and in this case the tungsten-selenium pair may function analogously to the molybdenum-sulfur pairing of some molybdenum cofactor-requiring enzymes.[92] One of the enzymes in the oxidoreductase family which sometimes employ tungsten (bacterial formate dehydrogenase H) is known to use a selenium-molybdenum version of molybdopterin.[93] Acetylene hydratase is an unusual metalloenzyme in that it catalyzes a hydration reaction. Two reaction mechanisms have been proposed, in one of which there is a direct interaction between the tungsten atom and the C≡C triple bond.[94] Although a tungsten-containing xanthine dehydrogenase from bacteria has been found to contain tungsten-molydopterin and also non-protein bound selenium, a tungsten-selenium molybdopterin complex has not been definitively described.[95]

In soil, tungsten metal oxidizes to the tungstate anion. It can be selectively or non-selectively imported by some prokaryotic organisms and may substitute for molybdate in certain enzymes. Its effect on the action of these enzymes is in some cases inhibitory and in others positive.[96] The soil's chemistry determines how the tungsten polymerizes; alkaline soils cause monomeric tungstates; acidic soils cause polymeric tungstates.[97]

Sodium tungstate and lead have been studied for their effect on earthworms. Lead was found to be lethal at low levels and sodium tungstate was much less toxic, but the tungstate completely inhibited their reproductive ability.[98]

Tungsten has been studied as a biological copper metabolic antagonist, in a role similar to the action of molybdenum. It has been found that tetrathiotungstates may be used as biological copper chelation chemicals, similar to the tetrathiomolybdates.[99]

In archaea

Tungsten is essential for some archaea. The following tungsten-utilizing enzymes are known:

- Aldehyde ferredoxin oxidoreductase (AOR) in Thermococcus strain ES-1

- Formaldehyde ferredoxin oxidoreductase (FOR) in Thermococcus litoralis

- Glyceraldehyde-3-phosphate ferredoxin oxidoreductase (GAPOR) in Pyrococcus furiosus

A wtp system is known to selectively transport tungsten in archaea:

- WtpA is tungsten-binding protein of ABC family of transporters

- WptB is a permease

- WtpC is ATPase[100]

Health factors

Because tungsten is a rare metal[101] and its compounds are generally inert, the effects of tungsten on the environment are limited.[102] The abundance of tungsten in the Earth's crust is thought to be about 1.5 parts per million. It is one of the more rare elements.

It was at first believed to be relatively inert and an only slightly toxic metal, but beginning in the year 2000, the risk presented by tungsten alloys, its dusts and particulates to induce cancer and several other adverse effects in animals as well as humans has been highlighted from in vitro and in vivo experiments.[103][104] The median lethal dose LD50 depends strongly on the animal and the method of administration and varies between 59 mg/kg (intravenous, rabbits)[105][106] and 5000 mg/kg (tungsten metal powder, intraperitoneal, rats).[107][108]

People can be exposed to tungsten in the workplace by breathing it in, swallowing it, skin contact, and eye contact. The National Institute for Occupational Safety and Health (NIOSH) has set a recommended exposure limit (REL) of 5 mg/m3 over an 8-hour workday and a short term limit of 10 mg/m3.[109]

Patent claim

Tungsten is unique amongst the elements in that it has been the subject of patent proceedings. In 1928, a US court rejected General Electric's attempt to patent it, overturning U.S. Patent 1,082,933 granted in 1913 to William D. Coolidge.[110][111][112]

See also

- Field emission gun

- Tungsten oxide

- List of chemical elements name etymologies

- List of chemical elements naming controversies

References

- Meija, Juris; et al. (2016). "Atomic weights of the elements 2013 (IUPAC Technical Report)". Pure and Applied Chemistry. 88 (3): 265–91. doi:10.1515/pac-2015-0305.

- Berger, Dan. "Why does Tungsten not 'Kick' up an electron from the s sublevel ?". Bluffton College, USA.

- Lide, David R., ed. (2009). CRC Handbook of Chemistry and Physics (90th ed.). Boca Raton, Florida: CRC Press. p. 6-134. ISBN 978-1-4200-9084-0.

- Tolias P. (2017). "Analytical expressions for thermophysical properties of solid and liquid tungsten relevant for fusion applications". Nuclear Materials and Energy. 13: 42–57. arXiv:1703.06302. Bibcode:2017arXiv170306302T. doi:10.1016/j.nme.2017.08.002.

- Lide, D. R., ed. (2005). "Magnetic susceptibility of the elements and inorganic compounds" (PDF). CRC Handbook of Chemistry and Physics (86th ed.). Boca Raton (FL): CRC Press. ISBN 978-0-8493-0486-6.

- Weast, Robert (1984). CRC, Handbook of Chemistry and Physics. Boca Raton, Florida: Chemical Rubber Company Publishing. p. E110. ISBN 978-0-8493-0464-4.

- wolfram on Merriam-Webster.

- wolfram on Oxford Dictionaries.

- "Tungsten". Oxford English Dictionary (3rd ed.). Oxford University Press. September 2005. (Subscription or UK public library membership required.)

- Zhang Y; Evans JRG and Zhang S (2011). "Corrected Values for Boiling Points and Enthalpies of Vaporization of Elements in Handbooks". J. Chem. Eng. Data. 56 (2): 328–337. doi:10.1021/je1011086.

- Daintith, John (2005). Facts on File Dictionary of Chemistry (4th ed.). New York: Checkmark Books. ISBN 978-0-8160-5649-1.

- Lassner, Erik; Schubert, Wolf-Dieter (1999). "low temperature brittleness". Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds. Springer. pp. 20–21. ISBN 978-0-306-45053-2.

- Gludovatz, B.; Wurster, S.; Weingärtner, T.; Hoffmann, A.; Pippan, R. (2011). "Influence of impurities on the fracture behavior of tungsten". Philosophical Magazine (Submitted manuscript). 91 (22): 3006–3020. Bibcode:2011PMag...91.3006G. doi:10.1080/14786435.2011.558861.

- Stwertka, Albert (2002). A Guide to the elements (2nd ed.). New York: Oxford University Press. ISBN 978-0-19-515026-1.

- Koribanics, N. M.; Tuorto, S. J.; Lopez-Chiaffarelli, N.; McGuinness, L. R.; Häggblom, M. M.; Williams, K. H.; Long, P. E.; Kerkhof, L. J. (2015). "Spatial Distribution of an Uranium-Respiring Betaproteobacterium at the Rifle, CO Field Research Site". PLOS One. 10 (4): e0123378. doi:10.1371/journal.pone.0123378. PMC 4395306. PMID 25874721.

- McMaster, J. & Enemark, John H. (1998). "The active sites of molybdenum- and tungsten-containing enzymes". Current Opinion in Chemical Biology. 2 (2): 201–207. doi:10.1016/S1367-5931(98)80061-6. PMID 9667924.

- Hille, Russ (2002). "Molybdenum and tungsten in biology". Trends in Biochemical Sciences. 27 (7): 360–367. doi:10.1016/S0968-0004(02)02107-2. PMID 12114025.

- Hammond, C. R. (2004). The Elements, in Handbook of Chemistry and Physics (81st ed.). CRC press. ISBN 978-0-8493-0485-9.

- Lassner, Erik; Schubert, Wolf-Dieter (1999). Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds. Springer. p. 9. ISBN 978-0-306-45053-2.

- Bean, Heather (October 19, 1998). Material Properties and Analysis Techniques for Tungsten Thin Films. frii.com

- Lita, A. E.; Rosenberg, D.; Nam, S.; Miller, A.; Balzar, D.; Kaatz, L. M.; Schwall, R. E. (2005). "Tuning of Tungsten Thin Film Superconducting Transition Temperature for Fabrication of Photon Number Resolving Detectors" (PDF). IEEE Transactions on Applied Superconductivity. 15 (2): 3528–3531. Bibcode:2005ITAS...15.3528L. doi:10.1109/TASC.2005.849033. Archived (PDF) from the original on 2013-05-13.

- Johnson, R. T.; O. E. Vilches; J. C. Wheatley; Suso Gygax (1966). "Superconductivity of Tungsten". Physical Review Letters. 16 (3): 101–104. Bibcode:1966PhRvL..16..101J. doi:10.1103/PhysRevLett.16.101.

- Autler, S. H.; J. K. Hulm; R. S. Kemper (1965). "Superconducting Technetium-Tungsten Alloys". Physical Review. 140 (4A): A1177–A1180. Bibcode:1965PhRv..140.1177A. doi:10.1103/PhysRev.140.A1177.

- Shailos, A.; W Nativel; A Kasumov; C Collet; M Ferrier; S Guéron; R Deblock; H Bouchiat (2007). "Proximity effect and multiple Andreev reflections in few-layer graphene". Europhysics Letters (EPL). 79 (5): 57008. arXiv:cond-mat/0612058. Bibcode:2007EL.....7957008S. doi:10.1209/0295-5075/79/57008.

- Kasumov, A. Yu.; K. Tsukagoshi; M. Kawamura; T. Kobayashi; Y. Aoyagi; K. Senba; T. Kodama; H. Nishikawa; I. Ikemoto; K. Kikuchi; V. T. Volkov; Yu. A. Kasumov; R. Deblock; S. Guéron; H. Bouchiat (2005). "Proximity effect in a superconductor-metallofullerene-superconductor molecular junction". Physical Review B. 72 (3): 033414. arXiv:cond-mat/0402312. Bibcode:2005PhRvB..72c3414K. doi:10.1103/PhysRevB.72.033414.

- Kirk, M. D.; D. P. E. Smith; D. B. Mitzi; J. Z. Sun; D. J. Webb; K. Char; M. R. Hahn; M. Naito; B. Oh; M. R. Beasley; T. H. Geballe; R. H. Hammond; A. Kapitulnik; C. F. Quate (1987). "Point-contact electron tunneling into the high-T_{c} superconductor Y-Ba-Cu-O". Physical Review B. 35 (16): 8850–8852. Bibcode:1987PhRvB..35.8850K. doi:10.1103/PhysRevB.35.8850. PMID 9941272.

- Danevich, F. A.; et al. (2003). "α activity of natural tungsten isotopes". Phys. Rev. C. 67 (1): 014310. arXiv:nucl-ex/0211013. Bibcode:2003PhRvC..67a4310D. doi:10.1103/PhysRevC.67.014310.

- Cozzini, C.; et al. (2004). "Detection of the natural α decay of tungsten". Phys. Rev. C. 70 (6): 064606. arXiv:nucl-ex/0408006. Bibcode:2004PhRvC..70f4606C. doi:10.1103/PhysRevC.70.064606.

- Sonzogni, Alejandro. "Interactive Chart of Nuclides". National Nuclear Data Center: Brookhaven National Laboratory. Archived from the original on 2008-05-22. Retrieved 2008-06-06.

- Emsley, John E. (1991). The elements (2nd ed.). New York: Oxford University Press. ISBN 978-0-19-855569-8.

- Morse, P. M.; Shelby, Q. D.; Kim, D. Y.; Girolami, G. S. (2008). "Ethylene Complexes of the Early Transition Metals: Crystal Structures of [HfEt4(C2H4)2−] and the Negative-Oxidation-State Species [TaHEt(C2H4)33−] and [WH(C2H4)43−]". Organometallics. 27 (5): 984–993. doi:10.1021/om701189e.

- Smith, Bradley J.; Patrick, Vincent A. (2000). "Quantitative Determination of Sodium Metatungstate Speciation by 183W N.M.R. Spectroscopy". Australian Journal of Chemistry. 53 (12): 965. doi:10.1071/CH00140.

- Scheele, Carl Wilhelm (1781) "Tungstens bestånds-delar" (Tungsten's constituents), Kungliga Vetenskaps Academiens Nya Handlingar (Royal Scientific Academy's New Proceedings), 2 : 89–95 (in Swedish).

- English translation on pp. 4–13 of: de Luyart, John Joseph and Fausto, with Charles Cullen, trans., A Chemical Analysis of Wolfram and Examination of a New Metal, Which Enters its Composition (London, England, G. Nicol, 1785).

- Saunders, Nigel (2004). Tungsten and the Elements of Groups 3 to 7 (The Periodic Table). Chicago, Illinois: Heinemann Library. ISBN 978-1-4034-3518-7.

- "ITIA Newsletter" (PDF). International Tungsten Industry Association. June 2005. Archived from the original on July 21, 2011. Retrieved 2008-06-18.CS1 maint: unfit url (link)

- "ITIA Newsletter" (PDF). International Tungsten Industry Association. December 2005. Archived from the original on July 21, 2011. Retrieved 2008-06-18.CS1 maint: unfit url (link)

- de Luyart, J.J. and F. (September 1783) "Análisis químico del volfram, y examen de un nuevo metal, que entra en su composición" (Chemical analysis of wolframite, and examination of a new metal, which enters into its composition), Extractos de las Juntas Generales celebradas por la Real Sociedad Bascongada de los Amigos del País en la ciudad de Vitoria por setiembre de 1783, pp. 46–88.

- de Luyart, John Joseph and Fausto, with Charles Cullen, trans., A Chemical Analysis of Wolfram and Examination of a New Metal, Which Enters its Composition (London, England, G. Nicol, 1785).

- Caswell, Lyman R. and Stone Daley, Rebecca W. (1999) "The Delhuyar brothers, tungsten, and Spanish silver," Bulletin for the History of Chemistry, 23 : 11–19. Available at: University of Illinois (USA) Archived 2015-12-30 at the Wayback Machine

- Watson, Greig (2014-06-06). "Vital WW1 metal 'in enemy hands'". BBC News. Retrieved 2018-02-10.

- Stevens, Donald G. (1999). "World War II Economic Warfare: The United States, Britain, and Portuguese Wolfram". The Historian. 61 (3): 539. doi:10.1111/j.1540-6563.1999.tb01036.x.

- Wheeler, L. Douglas (Summer 1986). "The Price of Neutrality: Portugal, the Wolfram Question, and World War II". Luso-Brazilian Review. 23 (1): 107–127. JSTOR 3513391.

- van der Krogt, Peter. "Wolframium Wolfram Tungsten". Elementymology & Elements Multidict. Archived from the original on 2010-01-23. Retrieved 2010-03-11.

- Holleman, Arnold F.; Wiberg, Egon; Wiberg, Nils (1985). "Mangan". Lehrbuch der Anorganischen Chemie (in German) (91–100 ed.). Walter de Gruyter. pp. 1110–1117. ISBN 978-3-11-007511-3.

- Pope, Michael T.; Müller, Achim (1997). "Polyoxometalate Chemistry: An Old Field with New Dimensions in Several Disciplines". Angewandte Chemie International Edition. 30: 34–48. doi:10.1002/anie.199100341.

- Tungsten. Mineral Commodity Summaries. USGS (2017)

- Shedd, Kim B. (December 2018) Tungsten. 2016 Minerals Yearbook. USGS

- Tungsten. Mineral Commodity Summaries. USGS (2018)

- Kristof, Nicholas D. (2010-06-27). "Death by Gadget". The New York Times. Archived from the original on 2016-08-31.

- "The Genocide Behind Your Smart Phone". The Daily Beast. July 16, 2010. Archived from the original on 2011-11-17.

- "Work starts on £130m Devon tungsten mine". BBC News. 9 June 2014. Archived from the original on 2014-12-05.

- "How Hemerdon mine lost £100m in just three years". Plymouth Herald. 12 October 2018. Retrieved 24 January 2019.

- Schey, John A. (1987). Introduction to Manufacturing Processes (2nd ed.). McGraw-Hill, Inc.

- Erik Lassner, Wolf-Dieter Schubert, Eberhard Lüderitz, Hans Uwe Wolf, "Tungsten, Tungsten Alloys, and Tungsten Compounds" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim. doi:10.1002/14356007.a27_229.

- Tan, C. (2018). "Selective laser melting of high-performance pure tungsten: parameter design, densification behavior and mechanical properties". Sci. Technol. Adv. Mater. 19 (1): 370–380. Bibcode:2018STAdM..19..370T. doi:10.1080/14686996.2018.1455154. PMC 5917440. PMID 29707073.

- Don Law-West; Louis Perron. "Tungsten". The Canadian Encyclopaedia. Retrieved 2009-05-05.

- Tungsten: The Element, History, Uses and Wedding Bands.tungstenworld.com

- de Laubenfels, Blair; Weber, Christy; Bamberg, Kim (2009). Knack Planning Your Wedding: A Step-by-Step Guide to Creating Your Perfect Day. Globe Pequot. pp. 35–. ISBN 978-1-59921-397-2.

- Schultz, Ken (2009). Ken Schultz's Essentials of Fishing: The Only Guide You Need to Catch Freshwater and Saltwater Fish. John Wiley and Sons. pp. 138–. ISBN 978-0-470-44431-3.

- "Tungsten Applications – Steel". Azom. 2000–2008. Archived from the original on 2008-08-15. Retrieved 2008-06-18.

- Ramakrishnan, P. (2007). "Powder metallurgy for Aerospace Applications". Powder metallurgy: processing for automotive, electrical/electronic and engineering industry. New Age International. p. 38. ISBN 978-81-224-2030-2.

- Tungsten Applications. wolfmet.com

- Dense Inert Metal Explosive (DIME). Defense-update.com. Retrieved on 2011-08-07.

- Delmon, Bernard & Froment, Gilbert F. (1999). Hydrotreatment and hydrocracking of oil fractions: proceedings of the 2nd international symposium, 7th European workshop, Antwerpen, Belgium, November 14–17, 1999. Elsevier. pp. 351–. ISBN 978-0-444-50214-8. Retrieved 18 December 2011.

- Mang, Theo & Dresel, Wilfried (2007). Lubricants and Lubrication. John Wiley & Sons. pp. 695–. ISBN 978-3-527-61033-4.

- Spivey, James J. (2002). Catalysis. Royal Society of Chemistry. pp. 239–. ISBN 978-0-85404-224-1. Retrieved 18 December 2011.

- "F1 Technique: The secrets of ballast in a Formula 1 car". Auto123.com. 2013-12-25. Retrieved 2019-02-03.

- Turrell, Kerry (2004). Tungsten. Marshall Cavendish. p. 24. ISBN 978-0-7614-1548-0.

- Duchaine, Simon (2018-03-09). "The Tungsten Carbide Nozzle Offers a Balance Between Wear Resistance and High Performance". 3dprint.com. Retrieved 2018-10-23.

- "Why Spirocore Tungsten C String". cello-strings.com. Archived from the original on 2016-05-10.

- "CRS Instruments". NASA. Archived from the original on 2017-02-01.

- Hesse, Rayner W. (2007). "tungsten". Jewelrymaking through history: an encyclopedia. Westport, Conn.: Greenwood Press. pp. 190–192. ISBN 978-0-313-33507-5.

- Gray, Theo (March 14, 2008). "How to Make Convincing Fake-Gold Bars". Popular Science. Archived from the original on December 29, 2014. Retrieved 2008-06-18.

- "Zinc Dimes, Tungsten Gold & Lost Respect Archived 2011-10-08 at the Wayback Machine", Jim Willie, Nov 18 2009

- "Largest Private Refinery Discovers Gold-Plated Tungsten Bar – Coin Update". news.coinupdate.com.

- Reuters (1983-12-22). "Austrians Seize False Gold Tied to London Bullion Theft". The New York Times. Archived from the original on 2012-03-27. Retrieved 2012-03-25.

- Tungsten filled Gold bars Archived 2012-03-26 at the Wayback Machine, ABC Bullion, Thursday, March 22, 2012

- Tungsten Alloy for Gold Substitution Archived 2012-03-22 at the Wayback Machine, China Tungsten

- DeGarmo, E. Paul (1979). Materials and Processes in Manufacturing (5th ed.). New York: MacMillan Publishing.

- Curry, Thomas S.; Dowdey, James E.; Murry, Robert C.; Christensen, Edward E. (1990-08-01). Christensen's physics of diagnostic radiology. pp. 29–35. ISBN 978-0-8121-1310-5. Archived from the original on 2017-11-11.

- Hasz, Wayne Charles et al. (August 6, 2002) "X-ray target" U.S. Patent 6,428,904

- "Non-Sag Doped Tungsten – Union City Filament". Union City Filament. Retrieved 2017-04-28.

- Li Yadong. "From Surfactant–Inorganic Mesostructures to Tungsten Nanowires". Cite journal requires

|journal=(help) - Volker Cimalla (2008). "Nanomechanics of single crystalline tungsten nanowires". Journal of Nanomaterials. 2008: 1–9. doi:10.1155/2008/638947.

- CNR Rao (2006). "High-sensitivity hydrocarbon sensors based on tungsten oxide nanowires". Journal of Materials Chemistry.

- Liu, M.; Peng, J.; et al. (2016). "Two-dimensional modeling of the self-limiting oxidation in silicon and tungsten nanowires". Theoretical and Applied Mechanics Letters. 6 (5): 195–199. doi:10.1016/j.taml.2016.08.002.

- JTL Thong (2010). "Thermal oxidation of polycrystalline tungsten nanowire" (PDF). Journal of Applied Physics. 108 (9): 094312–094312–6. Bibcode:2010JAP...108i4312Y. doi:10.1063/1.3504248. Archived (PDF) from the original on 2017-03-15.

- Pitts, R. A.; Carpentier, S.; Escourbiac, F.; Hirai, T.; Komarov, V.; Lisgo, S.; Kukushkin, A. S.; Loarte, A.; Merola, M.; Sashala Naik, A.; Mitteau, R. (2013-07-01). "A full tungsten divertor for ITER: Physics issues and design status". Journal of Nuclear Materials. Proceedings of the 20th International Conference on Plasma-Surface Interactions in Controlled Fusion Devices. 438: S48–S56. Bibcode:2013JNuM..438S..48P. doi:10.1016/j.jnucmat.2013.01.008. ISSN 0022-3115.

- Johnson JL, Rajagopalan KV, Mukund S, Adams MW. (5 March 1993). "Identification of molybdopterin as the organic component of the tungsten cofactor in four enzymes from hyperthermophilic Archaea". Journal of Biological Chemistry. 268 (7): 4848–52. PMID 8444863.CS1 maint: multiple names: authors list (link)

- Lassner, Erik (1999). Tungsten: Properties, Chemistry, Technology of the Element, Alloys and Chemical Compounds. Springer. pp. 409–411. ISBN 978-0-306-45053-2.

- Stiefel, E. I. (1998). "Transition metal sulfur chemistry and its relevance to molybdenum and tungsten enzymes" (PDF). Pure Appl. Chem. 70 (4): 889–896. CiteSeerX 10.1.1.614.5712. doi:10.1351/pac199870040889. Archived (PDF) from the original on 2008-12-03.

- Khangulov, S. V.; et al. (1998). "Selenium-Containing Formate Dehydrogenase H from Escherichia coli: A Molybdopterin Enzyme That Catalyzes Formate Oxidation without Oxygen Transfer". Biochemistry. 37 (10): 3518–3528. doi:10.1021/bi972177k. PMID 9521673.

- ten Brink, Felix (2014). "Chapter 2. Living on acetylene. A Primordial Energy Source". In Peter M.H. Kroneck; Martha E. Sosa Torres (eds.). The Metal-Driven Biogeochemistry of Gaseous Compounds in the Environment. Metal Ions in Life Sciences. 14. Springer. pp. 15–35. doi:10.1007/978-94-017-9269-1_2. ISBN 978-94-017-9268-4. PMID 25416389.

- Schrader, Thomas; Rienhofer, Annette; Andreesen, Jan R. (1999). "Selenium-containing xanthine dehydrogenase from Eubacterium barkeri". Eur. J. Biochem. 264 (3): 862–71. doi:10.1046/j.1432-1327.1999.00678.x. PMID 10491134.

- Andreesen, J. R.; Makdessi, K. (2008). "Tungsten, the Surprisingly Positively Acting Heavy Metal Element for Prokaryotes". Annals of the New York Academy of Sciences. 1125 (1): 215–229. Bibcode:2008NYASA1125..215A. doi:10.1196/annals.1419.003. PMID 18096847.

- Petkewich, Rachel A. (19 January 2009). "Unease over Tungsten". Chemical & Engineering News. 87 (3): 63–65. doi:10.1021/cen-v087n003.p063.

- Inouye, L. S.; et al. (2006). "Tungsten effects on survival, growth, and reproduction in the earthworm, eisenia fetida". Environmental Toxicology and Chemistry. 25 (3): 763–8. doi:10.1897/04-578R.1. PMID 16566161.

- McQuaid A; Lamand M; Mason J (1994). "Thiotungstate-copper interactions II. The effects of tetrathiotungstate on systemic copper metabolism in normal and copper-treated rats". J Inorg Biochem. 53 (3): 205–18. doi:10.1016/0162-0134(94)80005-7. PMID 8133256.

- Paul Blum, ed. (1 April 2008). Archaea: New Models for Prokaryotic Biology. Caister Academic Press. ISBN 978-1904455271.

- Brown, Mark (7 September 2011). "The Earth's most precious metals arrived on meteorites". wired.co.uk.

- Strigul, N; Koutsospyros, A; Arienti, P; Christodoulatos, C; Dermatas, D; Braida, W (2005). "Effects of tungsten on environmental systems". Chemosphere. 61 (2): 248–58. Bibcode:2005Chmsp..61..248S. doi:10.1016/j.chemosphere.2005.01.083. PMID 16168748.

- Laulicht, F.; Brocato, J.; Cartularo, L.; Vaughan, J.; Wu, F.; Vaughan, J.; Kluz, T.; Sun, H.; Oksuz, B. A.; Shen, S.; Peana, M.; Medici, S.; Zoroddu, M. A.; Costa, M. (2015). "Tungsten-induced carcinogenesis in human bronchial epithelial cells". Toxicology and Applied Pharmacology. 288 (1): 33–39. doi:10.1016/j.taap.2015.07.003. PMC 4579035. PMID 26164860.

- Zoroddu, M. A.; Medici, S.; Peana, M.; Nurchi, V. M.; Lachowicz, J. I.; Laulicht, J.; Costa, M. (2017). "Tungsten or Wolfram: Friend or Foe?". Curr. Med. Chem. 24 (1): 65–90. doi:10.2174/0929867324666170428105603. PMID 27855621.

- Koutsospyros, A.; Braida, W.; Christodoulatos, C.; Dermatas, D.; Strigul, N. (2006). "A review of tungsten: From environmental obscurity to scrutiny". Journal of Hazardous Materials. 136 (1): 1–19. doi:10.1016/j.jhazmat.2005.11.007. PMID 16343746.

- Lagarde, F.; Leroy, M. (2002). Metabolism and toxicity of tungsten in humans and animals. Metal Ions in Biological Systems. 39. pp. 741–59. doi:10.1201/9780203909331.ch22. ISBN 978-0-8247-0765-1. PMID 11913143. also reported in Astrid Sigel; Helmut Sigel (2002). Molybdenum and tungsten: their roles in biological processes. CRC Press. p. 741 ff. ISBN 978-0-8247-0765-1.

- Masten, Scott (2003). "Tungsten and Selected Tungsten Compounds – Review of Toxicological Literature" (PDF). National Institute of Environmental Health Sciences. Archived from the original (PDF) on 2009-03-25. Retrieved 2009-03-19.

- Marquet, P.; et al. (1997). "Tungsten determination in biological fluids, hair and nails by plasma emission spectrometry in a case of severe acute intoxication in man". Journal of Forensic Sciences. 42 (3): 527–30. doi:10.1520/JFS14162J. PMID 9144946.

- "CDC – NIOSH Pocket Guide to Chemical Hazards – Tungsten". www.cdc.gov. Archived from the original on 2015-11-25. Retrieved 2015-11-24.

- General Electric Co. v. De Forest Radio Co., 28 F.2d 641, 643 (3rd Cir. 1928)

- Guruswamy, Lakshman D.; McNeely, Jeffrey A. (1998). Protection of global biodiversity: converging strategies. Duke University Press. pp. 333–. ISBN 978-0-8223-2188-0.

- General Electric Co. v. De Forest Radio Co., 28 F.2d 641 (3d Cir. 1928).

External links

| Wikimedia Commons has media related to Tungsten. |

| Look up tungsten in Wiktionary, the free dictionary. |

- Properties, Photos, History, MSDS

- CDC – NIOSH Pocket Guide to Chemical Hazards

- Tungsten at The Periodic Table of Videos (University of Nottingham)

- Picture in the collection from Heinrich Pniok

- Elementymology & Elements Multidict by Peter van der Krogt – Tungsten

- International Tungsten Industry Association