Unified strength theory

The unified strength theory (UST).[1][2][3][4] proposed by Yu Mao-Hong is a series of yield criteria (see yield surface) and failure criteria (see Material failure theory). It is a generalized classical strength theory which can be used to describe the yielding or failure of material begins when the combination of principal stresses reaches a critical value.[5][6][7]

Mathematical Formulation

Mathematically, the formulation of UST is expressed in principal stress state as

(1a)

(1b)

where are three principal stresses, is the uniaxial tensile strength and is tension-compression strength ratio (). The unified yield criterion (UYC) is the simplification of UST when , i.e.

(2a)

(2b)

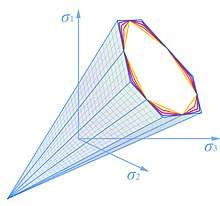

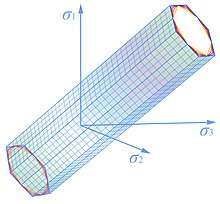

Limit surfaces of Unified Strength Theory

The limit surfaces of the unified strength theory in principal stress space are usually a semi-infinite dodecahedron cone with unequal sides. The shape and size of the limiting dodecahedron cone depends on the parameter b and . The limit surfaces of UST and UYC are shown as follows.

Derivation of Unified Strength Theory

Due to the relation (), the principal stress state () may be converted to the twin-shear stress state () or (). Twin-shear element models proposed by Mao-Hong Yu are used for representing the twin-shear stress state.[1] Considering all the stress components of the twin-shear models and their different effects yields the unified strength theory as

(3a)

(3b)

The relations among the stresses components and principal stresses read

(4a)

(4b)

(4c)

The and C should be obtained by uniaxial failure state

(5a)

(5b)

By substituting Eqs.(4a), (4b) and (5a) into the Eq.(3a), and substituting Eqs.(4a), (4c) and (5b) into Eq.(3b), the and C are introduced as

(6)

History of Unified Strength Theory

The development of the unified strength theory can be divided into three stages as follows.

1. Twin-shear yield criterion (UST with and )[8][9]

(7a)

(7b)

2. Twin-shear strength theory (UST with )[10].

(8a)

(8b)

3. Unified strength theory[1].

Applications of the Unified Strength theory

Unified strength theory has been used in Generalized Plasticity,[11] Structural Plasticity,[12] Computational Plasticity[13] and many other fields[14][15]

References

- Yu M. H., He L. N. (1991) A new model and theory on yield and failure of materials under the complex stress state. Mechanical Behaviour of Materials-6 (ICM-6). Jono M and Inoue T eds. Pergamon Press, Oxford, (3), pp. 841–846. https://doi.org/10.1016/B978-0-08-037890-9.50389-6

- Yu M. H. (2004) Unified Strength Theory and Its Applications. Springer: Berlin. ISBN 978-3-642-18943-2

- Zhao, G.-H.; Ed., (2006) Handbook of Engineering Mechanics, Rock Mechanics, Engineering Structures and Materials (in Chinese), China's Water Conservancy Resources and Hydropower Press, Beijing, pp. 20-21

- Yu M. H. (2018) Unified Strength Theory and Its Applications (second edition). Springer and Xi'an Jiaotong University Press, Springer and Xi'an. ISBN 978-981-10-6247-6

- Teodorescu, P.P. (Bucureşti). (2006). Review: Unified Strength Theory and its applications, Zentralblatt MATH Database 1931 – 2009, European Mathematical Society,Zbl 1059.74002, FIZ Karlsruhe & Springer-Verlag

- Altenbach, H., Bolchoun, A., Kolupaev, V.A. (2013). Phenomenological Yield and Failure Criteria, in Altenbach, H., Öchsner, A., eds., Plasticity of Pressure-Sensitive Materials, Serie ASM, Springer, Heidelberg, pp. 49-152.

- Kolupaev, V. A., Altenbach, H. (2010). Considerations on the Unified Strength Theory due to Mao-Hong Yu (in German: Einige Überlegungen zur Unified Strength Theory von Mao-Hong Yu), Forschung im Ingenieurwesen, 74(3), pp. 135-166.

- Yu M. H. (1961) Plastic potential and flow rules associated singular yield criterion. Res. Report of Xi'an Jiaotong University. Xi'an, China (in Chinese)

- Yu MH (1983) Twin shear stress yield criterion. International Journal of Mechanical Sciences, 25(1), pp. 71-74. https://doi.org/10.1016/0020-7403(83)90088-7

- Yu M. H., He L. N., Song L. Y. (1985) Twin shear stress theory and its generalization. Scientia Sinica (Sciences in China), English edn. Series A, 28(11), pp. 1174–1183.

- Yu M. H. et al., (2006) Generalized Plasticity. Springer: Berlin. ISBN 978-3-540-30433-3

- Yu M. H., Ma G. W., Li J. C. (2009) Structural Plasticity: Limit, Shakedown and Dynamic Plastic Analyses of Structures. ZJU Press and Springer: Hangzhou and Berlin. ISBN 978-3-540-88152-0

- Yu M. H., Li J. C. (2012) Computational Plasticity, Springer and ZJU Press: Berlin and Hangzhou. ISBN 978-3-642-24590-9

- Fan, S. C., Qiang, H. F. (2001). Normal high-velocity impaction concrete slabs-a simulation using the meshless SPH procedures. Computational Mechanics-New Frontiers for New Millennium, Valliappan S. and Khalili N. eds. Elsevier Science Ltd, pp. 1457-1462

- Guowei, M., Iwasaki, S., Miyamoto, Y. and Deto, H., 1998. Plastic limit analyses of circular plates with respect to unified yield criterion. International journal of mechanical sciences, 40(10), pp.963-976. https://doi.org/10.1016/S0020-7403(97)00140-9