Solder ball

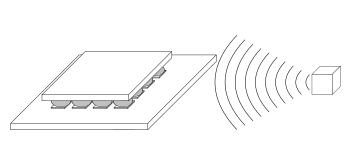

In integrated circuit packaging, a solder ball, also a solder bump (ofter referred to simply as "ball" or "bumps") is a ball of solder that provides the contact between the chip package and the printed circuit board, as well as between stacked packages in multichip modules[1]; in the latter case, they may be referred to as microbumps (μbumps, ubumps), since they are usually significantly smaller than the former. The solder balls can be placed manually or by automated equipment, and are held in place with a tacky flux.[2]

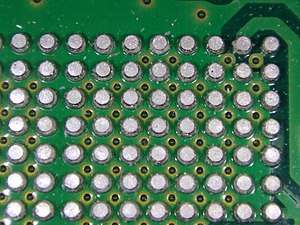

A grid array of solder balls under an integrated circuit chip, with the chip removed; the balls were left attached to the printed circuit board.

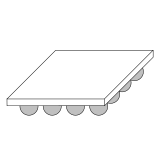

A MCM schematic for a stacked DRAM dice showing solder balls

A coined solder ball is a solder ball subject to coining, i.e., flattening to a shape resembling that of a coin, to increase contact reliability.[3]

Usage in flip chip method

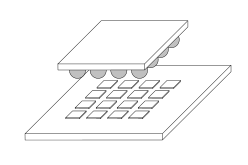

Pads

Pads Balls

Balls Alignment

Alignment Contact

Contact Solder reflow

Solder reflow Adhesive underfill

Adhesive underfill Final result

Final result

See also

- Head-in-pillow defect, a solder ball failure

References

- Definition of: solder ball, PC Magazine glossary

- Soldering 101 - A Basic Overview

- Patent US 7622325 B2, prior art description

This article is issued from Wikipedia. The text is licensed under Creative Commons - Attribution - Sharealike. Additional terms may apply for the media files.