Marvin Pipkin

Marvin Pipkin (November 18, 1889 – January 7, 1977) was an American chemist. During his time in the United States Army he worked on gas mask innovations. In his civilian life he invented a process for frosting the inside of incandescent light bulbs to cut down on the sharp glare and diffuse the light. He went on to make many other inventions and innovative improvements to the light bulb.

Marvin Pipkin | |

|---|---|

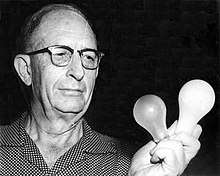

Marvin Pipkin showing his invention of the frosted soft white light bulbs | |

| Born | November 18, 1889 |

| Died | January 7, 1977 (aged 87) |

| Occupation | Chemist |

Early life and education

The fourth of six children, Pipkin was born November 18, 1889, south of Lakeland, Florida in a suburban community called Christina. His parents were Daniel M. Pipkin and Sarah Catherine (Moore) Pipkin. Daniel, his father, owned a citrus grove and was a farmer. He attended Lakeland elementary school and graduated from Bartow High School in Bartow, Florida. One of his classmates noted that his chemistry knowledge was more than all the rest in his class put together.[1]

Pipkin's first job was at a prospecting firm, where he worked for a year. Following that, he worked for about a year at International Mineral and Chemical Corporation of Bartow, where he was surrounded by college-educated people. Pipkin decided that he had to attend college in order to expand his ideas he had on certain chemistry theories. He went to Alabama Polytechnic Institute (API), graduating with a degree in Chemical Engineering in 1913. Pipkin then worked for a year in a fertilizer laboratory after which he returned to API where he gained his master's degree in 1915. He then attended Case Western Reserve University in Cleveland where he graduated with a doctorate degree in chemistry.[2]

Mid life

Pipkin enlisted in the Army in Jacksonville, Florida, on November 5, 1917.[3] Because the Germans were using lethal gas as a chemical weapon during World War I, gas mask research for protection of the soldiers and public had a high priority. With his chemistry background, Pipkin was posted to the Army's Gas Defense Department at General Electric's Nela Park in Cleveland.[4] The principles embodied in Pipkin's gas mask innovations remained in use throughout the twentieth century. He was promoted to the rank of a senior grade master engineer.[3] He remained at Nela Park after the war, and worked in General Electric’s bulb development department.[1]

Light bulb innovations

The public felt that the glare from clear transparent incandescent lamps gave off a harshness that was unwanted by most people. Another side effect was that they made it hard to see objects in immediate vicinity of the lamp. They desired a lamp that had a softer light with no glare. In 1920, General Electric developed a 30 watt light bulb that had outside etching as a frosting effect for the electric lamp. It effectively diffused the light to make it softer; however, it decreased the light produced by 15–25 percent. Another problem with the lamp was that fluorides came off in the sealing of the lamp and attacked the tungsten filament.[2] External etching of the globe bulb weakened it. The rough outside surface collected dust and dirt and was difficult to clean. The globes of the bulb were brittle and would often break with just ordinary handling.[5]

When Pipkin went to work for General Electric he was assigned the "impossible" task of finding a way to frost electric light bulbs on the inside without weakening the strength of the glass. Not being aware his assignment was a type of joke, he went about the task as if it was something that could be done and had been done before.[6] In 1925, Pipkin produced an innovative acid etching process for the inside of the globe of an electric lamp so that it did not deteriorate the lamp glass globe.[7][8] His was a two step acid process that etched the interior of glass with tiny crevasses on the first process as was the normal procedure done by other science engineers, but he added a second acid step that caused soft, rounded dimples from the crevasses which gave the bulbs added strength. There was minimal loss of diffusion of light with his innovation.[6] It left the outside of the globe of the glass lamp smooth that did not hold dust like a rough surface one did.[9][10] The first electric light bulb frosted on the inside with sufficient strength for ordinary handling that could be sold to the public was invented by Pipkin in 1925.[11][12][13]

This idea of having a second treatment to smooth out the fine-grained texture to dimples came about by an accident. Pipkin would often clean out the experimental bulbs with another solution of the acid, but in a weaker solution. If he let the filled bulb set for a while with this weaker solution it would clean out the etching previously done and return the glass globe to be transparent again. This saved the bulbs so they wouldn't be thrown away and could be experimented with again. One day, while he was pouring the weaker solution into a bulb, the phone rang. In the process of answering the phone, he accidentally tipped the bulb over before it had enough time to finish cleaning out the previous etching. When he returned to his work, he accidentally knocked the glass bulb off the workbench and onto the floor. To his surprise it did not shatter, as etched bulbs normally did, but bounced a few times and then rolled under the workbench. Pipkin was surprised to find that the bulb glass had somehow become much stronger. As it turned out, a short bath in the weaker cleaning solution, taken out before it had a chance to remove the etching, caused the etching of the first frosting treatment to form dimples in the etching, that strengthened the glass.[14]

Pipkin then did a demonstration of the bulbs' integrity to his supervisor at General Electric.[15] He presented to his supervisor six light bulbs that had been frosted on the inside. Some had just the one application of acid and others with his reinforced second treatment innovation, strengthening the glass globe. He placed the bulbs on his supervisor’s desk, standing up on their screw bottoms. He tipped the first three over, one at a time, to simulate a bulb being dropped from a small height. These were the bulbs treated with original single acid application, and as expected, all three bulbs shattered. He then tipped over the remaining three bulbs, which were tempered with his new two-step acid treatment. They remained unbroken, much to the surprise of his supervisor. Then, to further demonstrate the effectiveness of his tempering process, Pipkin took bulbs that had not shattered and dropped them again, this time allowing them to fall to the office floor. The bulbs bounced on the floor, and settled without breaking. This demonstrated Pipkin's innovation of a two-step acid etching process for frosting a glass light bulb interior, and creating a strong glass globe.[15] Pipkin's new frosted bulb revolutionized the industry, allowing the manufacture of frosted bulbs, that diffused the light without losing much intensity, and were strong enough to be commercially viable.[11][12][13] He went on to make many innovations to the light bulb and two decades later developed the soft white light bulb.[16]

Pipkin in 1947 invented an improved version of the process with silica coating that replaced the internal acid etching process.[17] The 1947 smoke-thin internal silica coating lasted for 30 years and had the trade name of Q coat.[18] The 100-watt Deluxe Soft-White light bulb was made from this. Pipkin is also credited with perfecting the photo flash bulb with several patents. Besides the frosted light bulb, Pipkin invented or improved many other products during his career with General Electric, including the 100 watt Deluxe-White bulb of the soft light bulb series.[2] These were noted in articles in Time magazine, Newsweek magazine, and the Saturday Evening Post magazine, as well in scientific journals.[16]

U.S. patents

- 1,520,437 Process of catalyzing gaseous reactions – filed on September 29, 1921 – patent granted December 23, 1924.

- 1,687,510 Electric Lamp Bulb – filed on June 29, 1925 – patent granted on October 16, 1928.

- 1,706,182 Colored or diffusing coating for incandescent lamps and similar articles – filed on September 20, 1926 – patent granted on March 19, 1929.

- 1,900,463 Bulb and method of coloring the same – filed on November 7, 1927 – patent granted on March 7, 1933.

- 2,053,164 Incandescent Lamp and method of manufacture – filed on December 31, 1931 – patent granted on September 1, 1936.

- 2,142,372 Flash Lamp – filed on March 18, 1937 – patent granted on January 3, 1939.

- 2,215,477 Method of manufacturing wire – filed on October 19, 1937 – patent granted on September 24, 1940.

- 2,285,125 Flash Lamp – filed on March 16, 1939 – patent granted on June 2, 1942.

- 2,291,983 Flash Lamp – filed on April 8, 1940 – patent granted on August 4, 1942.

- 2,306,563 Flash Lamp – filed on February 26, 1940 – patent granted on December 29, 1942.

- 2,361,495 Flash Lamp – filed on December 23, 1941 – patent granted on October 31, 1944.

- 2,473,888 (Jointly with Paul B. Jordan) Lead-in wire for electric lamps and similar devices – filed on June 10. 1947 – patent granted on June 21, 1949.

- 2,545,896 Electric Lamp, light diffusing coating therefor and method of manufacture – filed on January 7, 1948 – patent granted on March 20 1951.

- 2,615,472 Glass tubulature for feeding mercury – filed on December 16, 1947 – patent granted on October 28, 1952.

- 2,726,527 Flash Lamp – filed on October 30, 1951 – patent granted on December 13, 1955.

Personal life

Pipkin married to Kathryn Patricia Enright (1896–1957) on July 21, 1919;[1] they had three daughters.[2] He spoke with a pronounced southern accent.[1] Pipkin was a member of Tuscan Masonic Lodge, Knights of Pythias, and the American Chemical Society.[1] He was awarded the Charles A. Coffin award for his achievements in electric lamp improvements.[19]

Later life and death

Pipkin retired from the General Electric Nela Park laboratory in November 1954. He settled at his home on Beacon Road in Lakeland, Florida. He had lived in the town most of his life. Pipkin died at the General Hospital in Lakeland on January 7, 1977, of cancer. He was 87 years old. He is buried at the Fitzgerald Cemetery in Lakeland. At the time of his death he had three daughters still living. He also had three brothers and three sisters still living at that time.[1]

References

- McSwain, Peggy (March 18, 2010). "Marvin Pipkin (Nov. 18, 1889 – Jan. 7, 1977)". Polk County Family Biographies – Families – Obits. Retrieved December 19, 2017.

- Marvin Pipkin, 87, Lakeland Inventor, Dies From Cancer, The Ledger, January 8, 1977, pp. 1 & 7

- GE Cleveland 1920, p. 34.

- Keating 1954, p. 119.

- Payne 1927, p. 25.

- Lynn 1973, p. 57.

- Hendrickson III 2014, p. 564.

- "Notable People". The Estates of Cypress Trace. 2017. Retrieved December 21, 2017.

Marvin Pipkin is best known as the inventor of the inside-frost process of bulbs for incandescent lamps, which was developed in 1925, as well as the improved process developed in 1947, which consisted of an application of silica to the inside of a bulb.

- Cox 1979, p. 71.

- Federal Cases 1937, p. 887.

- Kane 1964, p. 229.

- Ohio Engineer 1951, p. 11.

- Encyclopedia Americana 1955, p. 185.

- Payne 1927, p. 24.

- "Light Bulb has interior frost". The San Bernardino County Sun. San Bernardino, California. January 21, 1928. p. 2 – via Newspapers.com

- "Marvin Pipkin". Schenectady Museum Association. 2017. Retrieved December 20, 2017.

He continued to work at NELA for many more years and eventually created the Soft-White light bulb nearly 25 years later.

- Bonnier Corp 1949, p. 125.

- Keating 1954, p. 226.

- Popular Science (1927), p. 24

Sources

- Bonnier Corp (March 1949). Popular Science. Bonnier Corporation. ISSN 0161-7370.CS1 maint: ref=harv (link)

- Cox, James A. (1979). Century of Light. Benjamin Company, Inc. ISBN 978-0-87502-062-4.CS1 maint: ref=harv (link)

- Encyclopedia Americana (1955). The Encyclopedia Americana. Americana Corporation.

In 1925, Marvin Pipkin invented the first commercially successful electric lamp bulb to be frosted on the inside.

CS1 maint: ref=harv (link) - Federal Cases (1937). Federal Supplement Cases. West Publishing Company.CS1 maint: ref=harv (link)

- GE Cleveland (1920). Nation in World War. Gilman printing Company.CS1 maint: ref=harv (link)

- Hendrickson III, Kenneth E. (2014). Encyclopedia Industrial Revolution. Rowman & Littlefield Publishers. ISBN 978-0-8108-8888-3.

Another innovation that helped modernize the light bulb was the invention by Marvin Pipkin of a process to frost the inside of the lamp bulb without weakening it.

CS1 maint: ref=harv (link) - Kane, Joseph Nathan (1964). Famous First Facts. H.W. Wilson.

The first electric lamp bulb frosted on the inside with sufficient strength for commercial handling was invented by Marvin Pipkin of the Incandescent Lamp Department of General Electric Company at Nela Park, Ohio. On June 29, 1925, he applied for a patent.

CS1 maint: ref=harv (link) - Keating, Paul W. (1954). Lamps for Brighter America. McGraw-Hill.CS1 maint: ref=harv (link)

- Lynn, Thomas (1973). 150 Biographical Illustrations.CS1 maint: ref=harv (link)

- Ohio Engineer (1951). Ohio State Engineer. Ohio State University.

The inside frosted lamp, designed by Marvin Pipkin in 1925–1926, was the first strong inside-frosted lamp.

CS1 maint: ref=harv (link) - Payne, Kenneth Wilcox (August 1927). Popular Science. Bonnier Corporation. ISSN 0161-7370.CS1 maint: ref=harv (link)