Unconventional wind turbines

Unconventional wind turbines are those that differ significantly from the most common types in use. As of 2012, the most common type of wind turbine is the three-bladed upwind horizontal-axis wind turbine (HAWT), where the turbine rotor is at the front of the nacelle and facing the wind upstream of its supporting turbine tower. A second major unit type is also classified by its axis: the vertical-axis wind turbine (VAWT), with blades extending upwards that are supported by a rotating framework.

Due to the large growth of the wind power industry and the length of its historical development dating back to windmills, many different wind turbine designs exist, are in current development, or have been proposed due to their unique features. The wide variety of designs reflects ongoing commercial, technological, and inventive interests in harvesting wind resources both more efficiently and to the greatest extent possible, with costs that may be either lower or greater than conventional three-bladed HAWT designs.

Some turbine designs that differ from the standard type have had limited commercial use, while others have only been demonstrated or are only theoretical concepts with no practical applications. Such unconventional designs cover a wide gamut of innovations, including different rotor types, basic functionalities, supporting structures and form-factors.

Modified horizontal

Twin-bladed rotor

Nearly all modern wind turbines uses rotors with three blades, but some use only two blades. This was the type used at Kaiser-Wilhelm-Koog, Germany, where a large experimental two-bladed unit—the GROWIAN, or Große Windkraftanlage (big wind turbine)—operated from 1983 to 1987. Other prototypes and several wind turbine types were also manufactured by NedWind. The Eemmeerdijk Wind Park in Zeewolde, Netherlands uses only two-bladed turbines. Wind turbines with two blades are manufactured by Nordic Windpower,[1] such as model # N 1000, and by GC China Turbine Corp.[2] The NASA wind turbines (1975-1996) each had 2-blade rotors, producing the same energy at lower cost than three-blade rotor designs.

Downwind rotor

Nearly all wind turbines are of an upwind design, meaning the rotor is in front of the nacelle when the wind is blowing. Some turbines are of a downwind design, meaning the rotor is behind the nacelle when the wind is blowing.

Ducted rotor

Still something of a research project,[3] the ducted rotor consists of a turbine inside a duct that flares out at the back. They are also referred as Diffuser-Augmented Wind Turbines (i.e. DAWT). The main advantage of the ducted rotor is that it can operate in a wide range of winds and generate a higher power per unit of rotor area. Another advantage is that the generator operates at a high rotation rate, so it doesn't require a bulky gearbox, allowing the mechanical portion to be smaller and lighter. A disadvantage is that (apart from the gearbox) it is more complicated than the unducted rotor and the duct is usually quite heavy, which puts an added load on the tower. The Éolienne Bollée is an example of a DAWT.

Co-axial, multi-rotor

Two or more rotors may be mounted to the same driveshaft, with their combined co-rotation together turning the same generator: fresh wind is brought to each rotor by sufficient spacing between rotors combined with an offset angle (alpha) from the wind direction. Wake vorticity is recovered as the top of a wake hits the bottom of the next rotor. Power has been multiplied several times using co-axial, multiple rotors in testing conducted by inventor and researcher Douglas Selsam, for the California Energy Commission in 2004. The first commercially available co-axial multi-rotor turbine is the patented dual-rotor American Twin Superturbine from Selsam Innovations in California, with 2 propellers separated by 12 feet. It is the most powerful 7-foot-diameter (2.1 m) turbine available, due to this extra rotor. In 2015, Iowa State University aerospace engineers Hui Hu and Anupam Sharma were optimizing designs of multi-rotor systems, including a horizontal-axis co-axial dual-rotor model. In addition to a conventional three-blade rotor, it has a smaller secondary three-blade rotor, covering the near-axis region usually inefficiently harvested. They were considering the overall efficiency of the wind farm, and checking many variations beyond the one mentioned. Preliminary results indicated 10-20% gains, less efficient than is claimed by existing counter-rotating designs but those are complex.[4]

Counter-rotating horizontal-axis

When a system expels or accelerates mass in one direction, the accelerated mass causes a proportional but opposite force on that system. The spinning blade of a single rotor wind turbine causes a significant amount of tangential or rotational air flow. The energy of this tangential air flow is wasted in a single-rotor propeller design. To use this wasted effort, the placement of a second rotor behind the first takes advantage of the disturbed airflow, and can gain up to 40% more energy from a given swept area as compared with a single rotor. Other advantages of contra-rotation include no gear boxes and auto-centering on the wind (no yaw motors/mechanism required). A patent application dated 1992 exists based on work done with the Trimblemill.[5]

When the counter-rotating turbines are on the same side of the tower, the blades in front are angled forwards slightly so as to avoid hitting the rear ones. If the turbine blades are on opposite sides of the tower, it is best that the blades at the back be smaller than the blades at the front and set to stall at a higher wind speed. This allows the generator to function at a wider wind speed range than a single-turbine generator for a given tower. To reduce sympathetic vibrations, the two turbines should turn at speeds with few common multiples, for example 7:3 speed ratio.

When land or sea area for a second wind turbine does not come at a premium the 40% gain with a second rotor has to be compared with a 100% gain via the expense of a separate foundation and tower with cabling for the second turbine. As of 2005, no large practical counter-rotating HAWTs are commercially sold.

Furling tail and twisting blades

In addition to variable pitch blades, furling tails and twisting blades are other improvements on wind turbines. Similar to the variable pitch blades, they may also greatly increase the efficiency of the turbine and be used in "do-it-yourself" construction[6]

Wind-mill style

De Nolet is a wind turbine in Rotterdam disguised as a windmill.

Fuller

The "Fuller" wind turbine is a fully enclosed wind turbine that uses boundary layers instead of blades.[7] Much like a Tesla turbine.

The concept is similar to a stack of disks on a central shaft, separated by a small air gap. The surface tension of air through the small gaps creates friction, making the disks rotate around the shaft. Vanes help direct the air for improved performance, hence it is not totally bladeless.

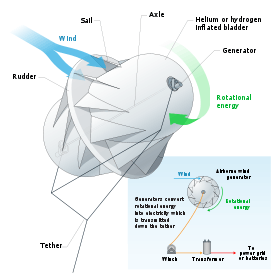

Aerial

It has been demonstrated that wind turbines could be flown in high-speed winds using high altitude wind power tactics, taking advantage of the winds at high altitudes. A system of automatically controlled tethered kites[8] could also be used to capture energy from high-altitude winds.

H-rotor

This is a vertical axis turbine, but it isn't favored because of its poor efficiency. One blade is pushed by the wind while the other is being pushed in the opposite direction. Consequently, only one blade is working at a time.

INVELOX

SheerWind's INVELOX technology was developed by Dr. Daryoush Allaei. The invention is really not a turbine, rather a wind capturing and delivery system to a turbine. In a sense, INVELOX is a wind injection system, much like a fuel injection system for cars. It works by accelerating the wind. A large intake captures wind, funnels it down using tapered pipes leading to a concentrator that ends in a Venturi section and finally wind exits from a diffuser. Turbine(s) are placed inside the Venturi section of the INVELOX. Inside the Venturi the dynamic pressure is very high while the static pressure is low. The Turbine converts dynamic pressure or kinetic energy to mechanical rotation and thereby to electrical power using a generator.[9][10] The device has been constructed and tested, but also criticized for lack of efficiency.[11] As of 2017, prototypes are being installed,[12][13] while another is inoperable.[14]

Saphonian

The Saphonian design produced by Tunisian startup Saphon Energy uses a dish to generate wind pressure and back-and-forth motion that drives a piston.[15][16]

Windbeam

Zephyr Energy Corporation’s patented Windbeam micro generator captures energy from airflow to recharge batteries and power electronic devices. The Windbeam’s novel design allows it to operate silently in wind speeds as low as 2 mph. The generator consists of a lightweight beam suspended by durable long-lasting springs within an outer frame. The beam oscillates rapidly when exposed to airflow due to the effects of multiple fluid flow phenomena. A linear alternator assembly converts the oscillating beam motion into usable electrical energy. A lack of bearings and gears eliminates frictional inefficiencies and noise. The generator can operate in low-light environments unsuitable for solar panels (e.g. HVAC ducts) and is inexpensive due to low cost components and simple construction. The scalable technology can be optimized to satisfy the energy requirements and design constraints of a given application.[17]

Wind belt

Invented by Shawn Frayne. A tensioned but flexible belt vibrates by the passing flow of air, due to aeroelastic flutter. A magnet, mounted at one end of the belt translates in and out of coiled windings producing electricity.[18][19] The company and product are no longer in existence.

Vortex bladeless

The Vortex Bladeless device deliberately maximizes vortex shedding, converting wind energy to fluttering of a lightweight vertical pole, then captures that energy with a generator at the bottom of the pole. [20][21][22] [23]

Vaneless ion wind generator

Piezoelectric

Another special type of wind turbines are the piezoelectric wind turbines. Turbines with diameters on the scale of 10 centimeters work by flexing piezoelectric crystals as they rotate, sufficient to power small electronic devices.[24]

Traffic-driven

A few proposals call for generating power from the otherwise wasted energy in the draft created by traffic.[25][26]

Blade Tip Power System (BTPS)

Designed by Imad Mahawili with Honeywell/WindTronics. This design uses many nylon blades and turns a permanent magnet generator inside out. The magnets are on the tips of the blades, and the stator is on the outside of the generator.

Solar chimney

Wind turbines may also be used in conjunction with a solar collector to extract the energy due to air heated by the Sun and rising through a large vertical Solar updraft tower.

Wind turbines on public display

Most wind turbines around the world belong to individuals or corporations who use them to generate electric power or to perform mechanical work. As such, wind turbines are primarily working devices. However, the large size and height above surroundings of modern industrial wind turbines, combined with their moving rotors, often makes them conspicuous. A few localities have exploited the attention-getting nature of wind turbines, either by putting visitor centers on their bases, or by providing viewing areas.[27] The wind turbines themselves are generally of conventional horizontal-axis, three-bladed design, and generate power to feed electrical grids, but they also serve the unconventional roles of technology demonstration, public relations, and education.

Rooftop wind-turbines

Wind-turbines can be installed on roofs of buildings, but this is less common than one might expect. Some examples include Marthalen Landi-Silo in Switzerland, Council House 2 in Melbourne, Australia. Ridgeblade in the UK is like a vertical wind turbine on its side mounted on the apex of a pitched roof. While the Ridgeblade is still in the design stage another example like this, already available in France is the Aeolta AeroCube. Discovery Tower is an office building in Houston, Texas, that incorporates 10 wind turbines in its architecture.

The Museum of Science in Boston, Massachusetts began constructing a rooftop Wind Turbine Lab in 2009.[28] The lab is testing nine wind turbines from five different manufacturers. Rooftop wind turbines may suffer from turbulence, especially in cities, which reduces power output and accelerates turbine wear.[29] The lab seeks to address the general lack of performance data for urban wind turbines.[28]

Due to structural limitations of buildings, limited space in urban areas, and safety considerations, wind turbines mounted on buildings are usually small (with nameplate capacities in the low kilowatts), rather than the megawatt-class wind turbines that are most economical for wind farms. An exception is the Bahrain World Trade Centre with three 225 kW wind turbines mounted between twin skyscrapers.

See also

References

- ↑ NedWind Rhenen bV NW 43/500 (Turbine), Nedwind website. Retrieved 27 January 2013.

- ↑ Why 2-Blade?, GC China Turbine Corporation website. Retrieved 27 January 2013.

- ↑ Uni-Stuttgart.de website Archived October 25, 2006, at the Wayback Machine.

- ↑ Iowa State engineers study the benefits of adding a second, smaller rotor to wind turbines.

- ↑ (WO1992012343) Wind Turbine, Patentscope website, 1992.

- ↑ Furling tail windturbines (page 18) PDF

- ↑ Fuller wind turbine

- ↑ Kite Energy Systems

- ↑ https://www.technologyreview.com/s/508136/ducted-wind-turbines-an-energy-game-changer/

- ↑ http://sheerwind.com

- ↑ "Sheerwind Invelox: All Hype, No Substance". CleanTechnica. 8 July 2014. Retrieved 24 September 2016.

- ↑ "Strange structure at Fort Custer harnesses wind power". WWMT. 16 March 2016. Retrieved 20 January 2017.

- ↑ "Nieuws - NedpowerSWH". NedpowerSWH. Retrieved 20 January 2017.

- ↑ "Vindturbinen skulle være en revolution: Nu står den stille". Ingeniøren. 18 January 2017. Retrieved 20 January 2017.

- ↑ http://newatlas.com/saphonian-bladeless-wind-turbine/24890/

- ↑ https://www.kcet.org/redefine/bladeless-wind-turbine-too-good-to-be-true

- ↑ http://www.zephyrenergy.com

- ↑ Ward, Logan. Windbelt, Cheap Generator Alternative, Set to Power Third World, Popular Mechanics website, October 1, 2007.

- ↑ Sofge, Erik. Shawn Frayne Makes Another Leap in Wind Power: Breakthrough Winner Update, Popular Mechanics website, December 18, 2009.

- ↑ Sam Davis. "A Wind Turbine Without Blades". 2015.

- ↑ Phil McKenna. "Bladeless Wind Turbines May Offer More Form Than Function". 2015.

- ↑ Liz Stinson. "The future of wind turbines? No blades". 2015.

- ↑ https://www.kcet.org/redefine/you-should-probably-be-skeptical-about-this-bladeless-wind-turbine

- ↑ Description of several types of wind turbines –including piezoelectric

- ↑ Power generation system utilizing wind draft from vehicular traffic

- ↑ Mark Oberholzer's roadside Darrieus wind turbine design

- ↑ Young, Kathryn (2007-08-03). "Canada wind farms blow away turbine tourists". Edmonton Journal. Archived from the original on 2009-04-25. Retrieved 2008-09-06.

- 1 2 "New US Rooftop Wind Turbine Lab". Renewable Energy World. 2009-06-01. Retrieved 2009-07-07.

- ↑ Leake, Jonathan (2006-04-16). "Home wind turbines dealt killer blow". London: The Sunday Times. Retrieved 2009-07-13.