Granular material

| Condensed matter physics |

|---|

|

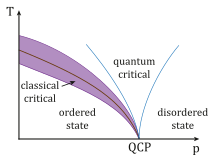

| Phases · Phase transition · QCP |

|

Phase phenomena |

|

Electronic phases |

|

Electronic phenomena |

|

Magnetic phases |

|

Scientists Van der Waals · Onnes · von Laue · Bragg · Debye · Bloch · Onsager · Mott · Peierls · Landau · Luttinger · Anderson · Van Vleck · Mott · Hubbard · Shockley · Bardeen · Cooper · Schrieffer · Josephson · Louis Néel · Esaki · Giaever · Kohn · Kadanoff · Fisher · Wilson · von Klitzing · Binnig · Rohrer · Bednorz · Müller · Laughlin · Störmer · Tsui · Abrikosov · Ginzburg · Leggett |

A granular material is a conglomeration of discrete solid, macroscopic particles characterized by a loss of energy whenever the particles interact (the most common example would be friction when grains collide).[1] The constituents that compose granular material must be large enough such that they are not subject to thermal motion fluctuations. Thus, the lower size limit for grains in granular material is about 1 µm. On the upper size limit, the physics of granular materials may be applied to ice floes where the individual grains are icebergs and to asteroid belts of the Solar System with individual grains being asteroids.

Some examples of granular materials are snow, nuts, coal, sand, rice, coffee, corn flakes, fertilizer, and bearing balls. Powders are a special class of granular material due to their small particle size, which makes them more cohesive and more easily suspended in a gas. Granular materials are commercially important in applications as diverse as pharmaceutical industry, agriculture, and energy production. Research into granular materials is thus directly applicable and goes back at least to Charles-Augustin de Coulomb, whose law of friction was originally stated for granular materials.[2]

The soldier/physicist Brigadier Ralph Alger Bagnold was an early pioneer of the physics of granular matter and whose book The Physics of Blown Sand and Desert Dunes[3] remains an important reference to this day.

According to material scientist Patrick Richard, "Granular materials are ubiquitous in nature and are the second-most manipulated material in industry (the first one is water)".[4]

In some sense, granular materials do not constitute a single phase of matter but have characteristics reminiscent of solids, liquids, or gases depending on the average energy per grain. However, in each of these states granular materials also exhibit properties which are unique.

Granular materials also exhibit a wide range of pattern forming behaviors when excited (e.g. vibrated or allowed to flow). As such granular materials under excitation can be thought of as an example of a complex system.

Granular solids

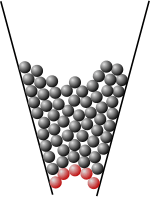

When the average energy of the individual grains is low and the grains are fairly stationary relative to each other, the granular material acts like a solid. In general, stress in a granular solid is not distributed uniformly but is conducted away along so-called force chains which are networks of grains resting on one another. Between these chains are regions of low stress whose grains are shielded for the effects of the grains above by vaulting and arching.

Granular gases

If the granular material is driven harder such that contacts between the grains become highly infrequent, the material enters a gaseous state. Correspondingly, one can define a granular temperature equal to the root mean square of grain velocity fluctuations that is analogous to thermodynamic temperature. Unlike conventional gases, granular materials will tend to cluster and clump due to the dissipative nature of the collisions between grains. This clustering has some interesting consequences. For example, if a partially partitioned box of granular materials is vigorously shaken then grains will over time tend to collect in one of the partitions rather than spread evenly into both partitions as would happen in a conventional gas. This effect, known as the granular Maxwell's demon, does not violate any thermodynamics principles since energy is constantly being lost from the system in the process.

Jamming transition

Granular systems are known to exhibit jamming and undergo a jamming transition which is thought of as a thermodynamic phase transition to a jammed state.[5] The Lubachevsky-Stillinger algorithm of jamming allows one to produce simulated jammed granular configurations. [6]

Pattern formation

Excited granular matter is a rich pattern-forming system. Some of the pattern-forming behaviours seen in granular materials are:

- The un-mixing or segregation of unlike grains under vibration and flow. An example of this is the so-called Brazil nut effect where Brazil nuts rise to the top of a packet of mixed nuts when shaken.The cause of this effect is that when shaken, granular (and some other) materials move in a circular pattern. some larger materials (Brazil nuts) get stuck while going down the circle and therefore stay on the top.

- The formation of structured surface or bulk patterns in vibrated granular layers. These patterns include but are not limited to stripes, squares and hexagons. These patterns are thought to be formed by fundamental excitations of the surface known as oscillons. The formation of ordered volumetric structures in granular materials is known as Granular Crystallisation, and involves a transition from a random packing of particles to an ordered packing such as hexagonal close-packed or body-centred cubic. This is most commonly observed in granular materials with narrow size distributions and uniform grain morphology.

- The formation of sand ripples, dunes, and sandsheets

Some of the pattern-forming behaviours have been possible to reproduce in computer simulations. [7][8] There are two main computational approaches to such simulations, time-stepped and event-driven, the former being the most efficient for a higher density of the material and the motions of a lower intensity, and the latter for a lower density of the material and the motions of a higher intensity.

Acoustic effects

.jpg)

Some beach sands, such as those of the aptly named Squeaky Beach, exhibit squeaking when walked upon. Some desert dunes are known to exhibit booming during avalanching or when their surface is otherwise disturbed. Granular materials discharged from silos produce loud acoustic emissions in a process known as silo honking.

Granulation

Granulation is the act or process in which primary powder particles are made to adhere to form larger, multiparticle entities called granules.

Modeling of granular materials

Several methods are available for modeling of granular materials. Most of these methods consist of the statistical methods by which various statistical properties, derived from either point data or an image, are extracted and used to generate stochastic models of the granular medium. A recent and comprehensive review of such methods is available in Tahmasebi and other (2017).[9]

Another alternative for building a pack of granular particles that recently has been presented is based on the level-set algorithm by which the real shape of the particle can be captured and reproduced through the extracted statistics for particles' morphologies[10].

See also

References

- ↑ Duran, J., Sands, Powders, and Grains: An Introduction to the Physics of Granular Materials (translated by A. Reisinger). November 1999, Springer-Verlag New York, Inc., New York, ISBN 0-387-98656-1.

- ↑ Rodhes, M (editor), Principles of powder technology, John Wiley & Sons, 1997 ISBN 0-471-92422-9

- ↑ Bagnold, R.A. 1941. The physics of blown sand and desert dunes. London: Methuen,

- ↑ Richard, P.; Nicodemi, Mario; Delannay, Renaud; Ribière, Philippe; Bideau, Daniel (2005). "Slow relaxation and compaction of granular systems". Nature Materials. 4 (2): 121–8. Bibcode:2005NatMa...4..121R. doi:10.1038/nmat1300. PMID 15689950.

- ↑ Haye Hinrichsen, Dietrich E. Wolf (eds), The Physics of Granular Media. 2004, Wiley-VCH Verlag GmbH & Co. ISBN 978-3-527-60362-6

- ↑ Kansal, Anuraag R.; Torquato, Salvatore; Stillinger, Frank H. (2002). "Computer Generation of Dense Polydisperse Sphere Packings" (PDF). The Journal of Chemical Physics. 117 (18): 8212. Bibcode:2002JChPh.117.8212K. doi:10.1063/1.1511510.

- ↑ John J. Drozd, Computer Simulation of Granular Matter: A Study of An Industrial Grinding Mill Archived 2011-08-18 at the Wayback Machine., Thesis, Univ. Western Ontario, Canada, 2004.

- ↑ A. D. Wissner-Gross, "Intruder dynamics on vibrofluidized granular surfaces", Materials Research Society Symposium Proceedings 1152E, TT03-01 (2009).

- ↑ Tahmasebi, Pejman; Sahimi, Muhammad; Andrade, José E. (2017-01-01). "Image-Based Modeling of Granular Porous Media". Geophysical Research Letters: 2017GL073938. Bibcode:2017GeoRL..44.4738T. doi:10.1002/2017GL073938. ISSN 1944-8007.

- ↑ Tahmasebi, Pejman (August 2018). "Packing of discrete and irregular particles" (PDF). Computers and Geotechnics. 100: 52–61. doi:10.1016/j.compgeo.2018.03.011.

External links

- Fundamentals of Particle Technology – free book

- Lu, Kevin; et al. (November 2007). "Shear-weakening of the transitional regime for granular flow". J. Fluid Mech. 587: 347–372. Bibcode:2007JFM...587..347L. doi:10.1017/S0022112007007331.

- Mester, L., The new physical-mechanical theory of granular materials. 2009, Homonnai, ISBN 978-963-8343-87-1

- Pareschi, L., Russo, G., Toscani, G., Modelling and Numerics of Kinetic Dissipative Systems, Nova Science Publishers, New York, 2006.