Conveyor belt

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems. A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley. There are two main industrial classes of belt conveyors; Those in general material handling such as those moving boxes along inside a factory and bulk material handling such as those used to transport large volumes of resources and agricultural materials, such as grain, salt, coal, ore, sand, overburden and more.

Overview

Conveyors are durable and reliable components used in automated distribution and warehousing. In combination with computer-controlled pallet handling equipment this allows for more efficient retail, wholesale, and manufacturing distribution. It is considered a labor saving system that allows large volumes to move rapidly through a process, allowing companies to ship or receive higher volumes with smaller storage space and with less labor expense.

Rubber conveyor belts are commonly used to convey items with irregular bottom surfaces, small items that would fall in between rollers (e.g. a sushi conveyor bar), or bags of product that would sag between rollers. Belt conveyors are generally fairly similar in construction consisting of a metal frame with rollers at either end of a flat metal bed. The belt is looped around each of the rollers and when one of the rollers is powered (by an electrical motor) the belting slides across the solid metal frame bed, moving the product. In heavy use applications the beds which the belting is pulled over are replaced with rollers. The rollers allow weight to be conveyed as they reduce the amount of friction generated from the heavier loading on the belting.

Belt conveyors can now be manufactured with curved sections which use tapered rollers and curved belting to convey products around a corner. These conveyor systems are commonly used in postal sorting offices and airport baggage handling systems. A sandwich belt conveyor uses two conveyor belts, face-to-face, to firmly contain the item being carried, making steep incline and even vertical-lift runs achievable.

Belt conveyors are the most commonly used powered conveyors because they are the most versatile and the least expensive. Product is conveyed directly on the belt so both regular and irregular shaped objects, large or small, light and heavy, can be transported successfully. These conveyors should use only the highest quality premium belting products, which reduces belt stretch and results in less maintenance for tension adjustments. Belt conveyors can be used to transport product in a straight line or through changes in elevation or direction. In certain applications they can also be used for static accumulation or cartons.

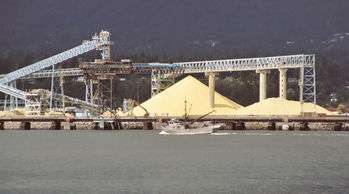

Belt conveyor systems at a Packing Depot

Belt conveyor systems at a Packing Depot Baggage Handling Belt Conveyor systems

Baggage Handling Belt Conveyor systems Belt conveyor from an open-pit lignite mine in Bavaria

Belt conveyor from an open-pit lignite mine in Bavaria

History

Primitive conveyor belts were used since the 19th century. In 1892, Thomas Robins began a series of inventions which led to the development of a conveyor belt used for carrying coal, ores and other products.[1][2] In 1901, Sandvik invented and started the production of steel conveyor belts. In 1905 Richard Sutcliffe invented the first conveyor belts for use in coal mines which revolutionized the mining industry. In 1913, Henry Ford introduced conveyor-belt assembly lines at Ford Motor Company's Highland Park, Michigan factory.[3] In 1972, the French society REI created in New Caledonia the longest straight-belt conveyor in the world, at a length of 13.8 km. Hyacynthe Marcel Bocchetti was the concept designer. In 1957, the B. F. Goodrich Company patented a conveyor belt that it went on to produce as the Turnover Conveyor Belt System. Incorporating a half-twist, it had the advantage over conventional belts of a longer life because it could expose all of its surface area to wear and tear. Möbius strip belts are no longer manufactured because untwisted modern belts can be made more durable by constructing them from several layers of different materials.[4] In 1970, Intralox, a Louisiana-based company, registered the first patent for all plastic, modular belting.

Structure

The belt consists of one or more layers of material. It is common for belts to have three layers: a top cover, a carcass and a bottom cover. The purpose of the carcass is to provide linear strength and shape. The carcass is often a woven or metal fabric having a warp & weft. The warp refers to longitudinal cords whose characteristics of resistance and elasticity define the running properties of the belt. The weft represents the whole set of transversal cables allowing to the belt specific resistance against cuts, tears and impacts and at the same time high flexibility. The most common carcass materials are steel, polyester, nylon, cotton and aramid. The covers are usually various rubber or plastic compounds specified by use of the belt.

Steel conveyor belts are used when high strength class is required. For example, the highest strength class conveyor belt installed is made of steel cords. This conveyor belt has a strength class of 10.000 N/mm and it operates at Chuquicamata mine, in Chile.[5] Polyester, nylon and cotton are popular with low strength classes. Aramid is used in the range 630 - 3500 N/mm. The advantages of using aramid are energy savings, enhanced lifetimes and improved productivity.[6][7] As an example, a 2250 N/mm, 3400 m long underground belt installed at Baodian Coal Mine, part of in Yanzhou Coal Mining Company, China, was reported to provide energy savings of >15%.[8]

Applications

Today there are different types of conveyor belts that have been created for conveying different kinds of material available in PVC and rubber materials. Material flowing over the belt may be weighed in transit using a beltweigher. Belts with regularly spaced partitions, known as elevator belts, are used for transporting loose materials up steep inclines. Belt Conveyors are used in self-unloading bulk freighters and in live bottom trucks. Belt conveyor technology is also used in conveyor transport such as moving sidewalks or escalators, as well as on many manufacturing assembly lines. Stores often have conveyor belts at the check-out counter to move shopping items. Ski areas also use conveyor belts to transport skiers up the hill.

Some of the major global conveyor belt manufacturers and service providers are Berndorf AG, Continental AG, Fenner plc, Kale Conveyor, Terra Nova Technologies, ThyssenKrupp, HESE Maschinenfabrik GmbH and Tenova Takraf. [9]

Long belt conveyors

_-_BEIC_6328731.jpg)

The longest belt conveyor system in the world is in Western Sahara. It was built in 1972 by Friedrich Krupp GmbH (now thyssenkrupp) and is 98 km (61 mi) long, from the phosphate mines of Bu Craa to the coast south of El-Aaiun.[10]

The longest conveyor system in an airport is the Dubai International Airport baggage handling system at 63 km (39 mi). It was installed by Siemens and commissioned in 2008, and has a combination of traditional belt conveyors and tray conveyors.[11]

Boddington Bauxite Mine in Western Australia is officially recognised as having the world's longest and second-longest single belts with a 31-kilometre-long (19 mi) belt feeding a 20 km (12.5 miles) long belt. This system feeds bauxite through the difficult terrain of the Darling Ranges to the Worsley Alumina refinery. The longest single-belt international conveyor runs from Meghalaya in India to a cement factory at Chhatak Bangladesh.[12][13][14] It is about 17 km long and conveys limestone and shale at 960 tons/hour, from the quarry in India to the cement factory (7 km long in India and 10 km long in Bangladesh). The conveyor was engineered by AUMUND France and Larsen & Toubro. The conveyor is actuated by three synchronized drive units for a total power of about 1.8 MW supplied by ABB (two drives at the head end in Bangladesh and one drive at the tail end in India). The conveyor belt was manufactured in 300-meter lengths on the Indian side and 500-meter lengths on the Bangladesh side, and was installed on-site by BeltPro (formerly NILOS India). The idlers, or rollers, of the system are unique in that they are designed to accommodate both horizontal and vertical curves along the terrain. Dedicated vehicles were designed for the maintenance of the conveyor, which is always at a minimum height of 5 metres (16 ft) above the ground to avoid being flooded during monsoon periods.

Belt conveyor safety system

Conveyors used in industrial settings include tripping mechanisms such as trip cords along the length of the conveyor. This allows for workers to immediately shut down the conveyor when a problem arises. Warning alarms are included to notify employees that a conveyor is about to turn on. In the United States, the Occupational Safety and Health Administration has issued regulations for conveyor safety, as OSHA 1926.555.[15]

See also

References

- ↑ "Thomas Robins, Inventor, 89, Dies. Developer of Heavy-Duty Conveyor Belt Had Headed Hewitt-Robins Company". The New York Times. November 5, 1957. Archived from the original on December 25, 2013. Retrieved 2013-12-18.

Thomas Robins, founder and former chairman of the board of the Hewitt-Robins Company here, died today in the Nestledown Convalescent Home after an illness of several months, His age was 89. He invented the heavy-duty belt conveyor.

- ↑

- ↑ Hounshell, David A. (1984), From the American System to Mass Production, 1800-1932: The Development of Manufacturing Technology in the United States, Baltimore, Maryland: Johns Hopkins University Press, ISBN 978-0-8018-2975-8, LCCN 83016269

- ↑ "Mobius band". Daviddarling.info. 2007-02-01. Archived from the original on 2013-04-03. Retrieved 2013-03-27.

- ↑ "Archived copy". Archived from the original on 2017-11-10. Retrieved 2017-11-10. . "Awarding of the World's Most Powerful Belt Conveyor System" Mining.com, 15-04-2016. Retrieved on 2017-10-11

- ↑ Lodewijks G. (2011), "The Next Generation Low Loss Conveyor Belts", Proceedings of the Beltcon 16 conference, Johannesburg, Republic of South Africa, August 3–4, 2011.

- ↑ "Archived copy". Archived from the original on 2017-11-10. Retrieved 2017-11-10. . Engineering and Mining Journal 5-12-2014. Retrieved on 2017-10-11

- ↑ Ven H.J.F.M., Beers H., Jinglei W, Martins C., Mendez E. (2017), "Aramid in conveyor belts in operation: extended lifetime, energy savings and environmental effects", Proceedings of the Beltcon 19 conference, Pretoria, Republic of South Africa, August 2–3, 2017"

- ↑ Digiscend (October 2014). "Conveyor Belt System Services". Digiscend.com. Archived from the original on 2014-10-31.

- ↑ "Morocco's fish fight: High stakes over Western Sahara". BBC News. 15 December 2011. Archived from the original on 16 December 2011.

- ↑ "Dubai International Airport: A Baggage Handling System for the gate to the Arab World" (PDF), Seimens AG, 2009, archived (PDF) from the original on 2013-10-19

- ↑ Alspaugh, Mark, Bulk Material Handling By Conveyor Belt 7, p 83 ISBN 0-87335-260-2

- ↑ "Asian Development Bank description of the Lafarge Surma project". Pid.adb.org. Archived from the original on 2014-01-11. Retrieved 2013-03-27.

- ↑ "Stoppage of limestone supply to Lafarge Surma Indian SC issues showcause notice on central, Meghala". Mines and Communities. 2007-06-20. Archived from the original on 2014-01-11. Retrieved 2013-03-27.

- ↑ "Safety and Health Regulations for Construction, Conveyors". US Department of Labor. 2010-01-21. Archived from the original on 2013-12-16. Retrieved 2013-12-16.

External links

| Wikimedia Commons has media related to Conveyor belts. |