Cavity wall

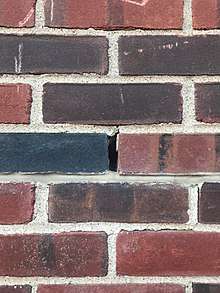

Cavity walls consist of two "skins" separated by a hollow space (cavity).[1] The skins are commonly masonry, such as brick or concrete block. Masonry is an absorbent material, and therefore will slowly draw rainwater or even humidity into the wall, as well as from the inside of the house as from outside. The cavity serves as a way to drain water back out through weep holes at the base of the wall system or above windows. The weep holes allow wind to create an air stream through the cavity and the stream removes evaporated water from the cavity to the outside. Usually weep holes are created by intentionally leaving several vertical joints, also open head joints, open about two meters apart at the base of in every story. Weep holes are also placed above windows to prevent dry rot of a wooden window frame. A cavity wall with masonry as both inner and outer skins is more commonly referred to as a double wythe masonry wall.[2]

History

The typical cavity wall method of construction was introduced in Northwest Europe during the 19th century and gained widespread use from the 1920s. In some early examples stones were used to tie the two leaves of the cavity wall together,[3] while in the 20th century metal ties came into use. Initially cavity widths were extremely narrow and were primarily implemented to prevent the passage of moisture into the interior of the building. The widespread introduction of insulation into the cavity began in the 1970s with it becoming compulsory in building regulations during the 1990s.

Advantages

- Resist wind driven rain

- Insulation provided by slow moving airfilms & airgap

- Enables use of low cost nonrigid insulation batts

Tie types

- Stone

- Brick

- Iron - prone to rusting & expanding

- Stainless steel now the norm

- Plastic

- Elastic

Components

A cavity wall is composed of two masonry walls separated by a continuous air space in between the outer and the inner wall. The outer wall is the brick wall that faces the outside of the building structure.[1] The inner wall, separated from the outer wall by a continuous air space or the cavity, is the wall on the interior of the building structure. The inner wall may be constructed of masonry units such as concrete block, structural clay, brick or in some other cases reinforced concrete.[1] These two walls have to be fastened together with metal ties or bonding blocks.[2] The ties will allow the cavity wall to be strong.

The water barrier is a thin membrane that will keep moisture away from the cavity side of the interior wall.

In cavity walls the flashing component is very important for the overall water management of the wall.[4] The main purpose of the flashing is to direct water out of the cavity. Metal flashing will usually extend from the interior wall through the outer wall and a weep hole with a downward curve should be provided in order to get water out. Flashing system in cavity walls are typically located close to the base of the wall, so that it will collect, on the bottom, all the water that goes down the wall.

Weep holes are drainage holes left in the exterior wall of the cavity wall, to provide an exit way for water in the cavity.

Expansion and control joints do not have to be aligned in cavity walls.[5]

In modern cavity wall construction, cavity insulation is typically added. This construction makes possible to add a continuous insulation layer in between the two wythes and, vertically, through the slabs, which minimizes thermal bridges.[5]

Wall issues

Breathing Performance: Early cavity wall buildings are structures that exchange moisture readily with the indoor and outdoor environment. Materials used in repairs must be selected with care so they do not affect the breathing performance of the materials.[4]

Cavity wall insulation installed in older buildings can create problems with moisture retention. [4]

Thermal mass cavity walls are thick walls. These help stabilize the interior environment of a building better that the thinner modern walls.[4]

Environmental Influences: The orientation or design of a building may affect the performance of different façades on a building. Some walls may receive more rainwater and wind than others depending in their orientation or protection to some of the faces. [4]

Damp: Moisture is one of the main problems in materials weathering. [4]

Salts

References

- ↑ "Cavity" def. 4. Oxford English Dictionary Second Edition on CD-ROM (v. 4.0) © Oxford University Press 2009

- ↑ Matthys, John H.. Masonry: components to assemblages. Philadelphia, PA: ASTM, 1990. 175. Print.

- ↑ "AECB Forum : Victorian cavity wall thread". Archived from the original on 2007-09-28. Retrieved 2006-12-15.

- ↑ "Masonry wall flashings". Masoncontractors.org. 2012-05-11. Retrieved 2018-08-27.

- 1 2 1884-1963., Ramsey, Charles George, (2000). Ramsey/Sleeper architectural graphic standards. Sleeper, Harold Reeve, 1893-1960., Hoke, John Ray, 1950- (10th ed.). New York: John Wiley & Sons. ISBN 0471348163. OCLC 43286484.

- Allen, E., & Iano, J. (1986). Fundamentals of building construction (5th ed.). New York: Wiley.

- Ching, F. D., Onouye, B., & Zuberbuhler, D. (2014). Building structures illustrated (2nd ed.). Hoboken (N.J.): J. Wiley & Sons.

- Ching, F. (2012). A visual dictionary of architecture. Hoboken, NJ: Wiley.

- Whittemore, H. L. (1939). Structural properties of a concrete-block cavity-wall construction sponsored by the National Concrete Masonry Association. Washington, D.C.: U.S. Dept. of Commerce, National Bureau of Standards .

- Whittemore, H. L. b. 1876. (1939). Structural properties of a brick cavity-wall construction sponsored by the Brick Manufacturers Association of New York, Inc.. Washington, D.C.: U.S. Dept. of Commerce, National Bureau of Standards .

- Whittemore, H. L. (1939). Structural properties of a reinforced-brick wall construction and a brick-tile cavity-wall construction sponsored by the Structural Clay Products Institute. Washington, D.C.: U.S. Dept. of Commerce, National Bureau of Standards .