Air compressor

An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). By one of several methods, an air compressor forces more and more air into a storage tank, increasing the pressure. When tank pressure reaches its engineered upper limit the air compressor shuts off. The compressed air, then, is held in the tank until called into use.[1] The energy contained in the compressed air can be used for a variety of applications, utilizing the kinetic energy of the air as it is released and the tank depressurizes. When tank pressure reaches its lower limit, the air compressor turns on again and re-pressurizes the tank. An air compressor must be differentiated from pump because it works for any gas/air and pump work on liquid.

Classification

Compressors can be classified according to the pressure delivered:

- Low-pressure air compressors (LPACs), which have a discharge pressure of 150 psi or less

- Medium-pressure compressors which have a discharge pressure of 151 psi to 1,000 psi

- High-pressure air compressors (HPACs), which have a discharge pressure above 1,000 psi[2]

They can also be classified according to the design and principle of operation:

- Single-Stage Reciprocating Compressor

- Two-Stage Reciprocating Compressor

- Compound Compressor

- Rotary-screw compressor

- Rotary Vane Compressor

- Scroll Compressor

- Turbo compressor

- Axial Compressor

Displacement type

There are numerous methods of air compression, divided into either positive-displacement or roto-dynamic types.[3]

Positive displacement

Positive-displacement compressors work by forcing air into a chamber whose volume is decreased to compress the air. Once the maximum pressure is reached, a port or valve opens and air is discharged into the outlet system from the compression chamber.[4] Common types of positive displacement compressors are

- Piston-type: air compressors use this principle by pumping air into an air chamber through the use of the constant motion of pistons. They use one-way valves to guide air into and out of a chamber whose base consists of a moving piston. When the piston is on its down stroke, it draws air into the chamber. When it is on its up stroke, the charge of air is forced out and into a storage tank. Piston compressors generally fall into two basic categories, single-stage and two-stage. Single stage compressors usually fall into the fractional through 5 horsepower range. Two-stage compressors normally fall

_type_refrigerated_compressed_air_dryer.jpg) Technical Illustration of a two-stage air compressorinto the 5 through 30 horsepower range. Two-stage compressors provide greater efficiency than their single-stage counterparts. For this reason, these compressors are the most common units within the small business community. The capacities for both single-stage and two-stage compressors is generally provided in horsepower (HP), Standard Cubic feet per Minute (SCFM)* and Pounds per Square Inch (PSI). *To a lesser extent, some compressors are rated in Actual Cubic Feet per Minute (ACFM). Still others are rated in Cubic Feet per Minute (CFM). Using CFM to rate a compressor is incorrect because it represents a flow rate that is independent of a pressure reference. i.e. 20 CFM at 60 PSI.

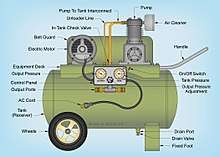

Technical Illustration of a two-stage air compressorinto the 5 through 30 horsepower range. Two-stage compressors provide greater efficiency than their single-stage counterparts. For this reason, these compressors are the most common units within the small business community. The capacities for both single-stage and two-stage compressors is generally provided in horsepower (HP), Standard Cubic feet per Minute (SCFM)* and Pounds per Square Inch (PSI). *To a lesser extent, some compressors are rated in Actual Cubic Feet per Minute (ACFM). Still others are rated in Cubic Feet per Minute (CFM). Using CFM to rate a compressor is incorrect because it represents a flow rate that is independent of a pressure reference. i.e. 20 CFM at 60 PSI. Technical Illustration of a portable single-stage air compressor

Technical Illustration of a portable single-stage air compressor - Rotary screw compressors: use positive-displacement compression by matching two helical screws that, when turned, guide air into a chamber, whose volume is decreased as the screws turn.

- Vane compressors: use a slotted rotor with varied blade placement to guide air into a chamber and compress the volume. This type of compressor delivers a fixed volume of air at high pressures.

Dynamic displacement

Dynamic displacement air compressors include centrifugal compressors and axial compressors. In these types, a rotating component imparts its kinetic energy to the air which is eventually converted into pressure energy. These use centrifugal force generated by a spinning impeller to accelerate and then decelerate captured air, which pressurizes it.

Cooling

Due to adiabatic heating, air compressors require some method of disposing of waste heat. Generally this is some form of air- or water-cooling, although some (particularly rotary type) compressors may be cooled by oil (that is then in turn air- or water-cooled).[5] The atmospheric changes are also considered during cooling of compressors.

Applications

Air compressors have many uses, including: supplying high-pressure clean air to fill gas cylinders, supplying moderate-pressure clean air to a submerged surface supplied diver, supplying moderate-pressure clean air for driving some office and school building pneumatic HVAC control system valves, supplying a large amount of moderate-pressure air to power pneumatic tools, such as jackhammers, filling high pressure air tanks (HPA), for filling tires, and to produce large volumes of moderate-pressure air for large-scale industrial processes (such as oxidation for petroleum coking or cement plant bag house purge systems).[6]

Most air compressors either are reciprocating piston type, rotary vane or rotary screw. Centrifugal compressors are common in very large applications. There are two main types of air-compressor pumps: oil-lubed and oil-less. The oil-less system has more technical development, but is more expensive, louder and lasts for less time than oil-lubed pumps. The oil-less system also delivers air of better quality.

The most common types of air compressors are: electric or gas/diesel powered compressors. The power of a compressor is measured in HP (horsepower) and CFM (cubic feet per minute of intake air).[7] The gallon size of the tank specifies the volume of compressed air (in reserve) available. Gas/diesel powered compressors are widely used in remote areas with problematic access to electricity. They are noisy and require ventilation for exhaust gases. Electric powered compressors are widely used in production, workshops and garages with permanent access to electricity. Common workshop/garage compressors are 110-120 Volt or 230-240 Volt. Compressor tank shapes are: "pancake", "twin tank", "horizontal", and "vertical". Depending on a size and purpose compressors can be stationary or portable.

Maintenance

To ensure all compressor types run efficiently with no leaks, it is imperative to perform routine maintenance, such as monitoring and replacing air compressor fittings.[8] It is suggested that air compressor owners perform daily inspections of their equipment, such as:

- Checking for oil and air leaks

- Checking the differential pressure in the compressed air filter

- Determining whether or not the oil in the compressor should be changed

- Verifying safe operating temperature

- Draining condensation

See also

References

- ↑ "How Do Air Compressors Work?". Popular Mechanics. 2015-03-18. Retrieved 2017-01-12.

- ↑ "CLASSIFICATION OF AIR COMPRESSORS". www.tpub.com. Retrieved 2017-01-12.

- ↑ "Air Compressor Types and Controls". Natural Resources Canada.

- ↑ "Compressor Selection Basics: Positive Displacement versus Dynamic Compression". Retrieved 2017-01-12 – via The 5th Utility.

- ↑ "Types of Air Compressors". The Engineering ToolBox.

- ↑ "Applications for Compressors". www.industry.siemens.com. Retrieved 2017-01-12.

- ↑ "Evaluating True Horsepower and CFM Ratings of Air Compressors".

- ↑ "Air Compressor Fittings". Compressed Air Systems. Retrieved 2017-01-12.

External links